Renishaw, Inc.

1001 Wesemann Dr.

West Dundee, IL 60118 US

847-286-9953

renishaw.com

IS THIS YOUR COMPANY?

Video Gallery

Renishaw trade shows in 2024 - come visit us!

Come visit us at one of our trade shows around the globe! For expert advice, knowledge and to see our products in action.

Non-contact tool setter – How to set up a tool profile check on the NC4 | Renishaw

In this tool setting how-to video, Dan and Iain explain how to check a tool's profile using NC4+ Blue tool setter. They discuss why ...

RLS encoders and Renishaw help place Dynisma in pole position

Renishaw and RLS provided magnetic encoders and technical support to British-based Dynisma for its latest dynamic motion ...

Equator gauging system reduces inspection time of NIMS metalworking training parts by 85%

To uphold student skill levels to current manufacturing industry standards, many trade schools in the USA have aligned their ...

As Seen On Modern Machine Shop

Renishaw, Inc. Supplies the Following Products

- Attachments & Accessories

- CAD/CAM for Additive Manufacturing

- Calibration Equipment

- Calibration Software

- Clamps & Fixturing Devices

- Comparators, Optical & Other

- Consulting

- Consulting Services, R&D Institutes, Labs

- Coordinate Measuring Machines (CMMs)

- Data Collection Devices for Gaging, SPC, etc.

- Digitizing/Scanning Systems

- Encoders/Resolvers

- Engineering Analysis & Simulation

- Fixturing Systems

- Flatness Measuring Equipment

- for Metal Parts

- Gages, Electronic/Digital

- Gages, Mechanical

- Gear Inspection Equipment

- Interferometers

- Job & File Management Software

- Laser Accessories & Supplies

- Laser Measurement Systems

- Leasing & Financing

- Linear Scales

- Maintenance & Repair

- Material Testing & Analysis Equipment

- Metal

- NC Program Optimization

- On-Machine Probes

- Part Design Software

- Powder Bed Fusion

- Powder Metals

- Probes, Electromechanical

- Quality & Measurement

- Quality Documentation

- Replacement & Repair Parts

- Retrofitting, Rebuilding, Remanufacturing Services

- Roundness Measuring Equipment

- Servo Motors, Linear

- Software, Other Manufacturing

- Surface Finish Measuring Equipment

- Surface Plates

- Tool Condition Monitoring Systems

- Tool Presetters

- Tool Presetting Equipment

- Toolchangers

- Toolholders

- Trade Associations, Societies, Gov. Agencies

- Training

- Training & Consultancy for Additive Manufacturing

- Vision Systems

Trade Names Offered by Renishaw, Inc.

- OTS

- OMP40

- RFP

- NC4

- XR20-W

- PH20

- Renscan5

- XK10

- Equator 500

- SiGNUM

- RoLin

- RENGAGE

- QC20-W ballbar

- TONiC

- RMP40

- SFP2

- RVP

- RTS

- Central

- MODUS

- FASTRACK

- Sprint

- InfiniAM

- ATOM

- Revo

- XM-60

- AxiSet

- UCC

- Equator 300

- QuantAM

- RenAM 550E

- XL-80

- OSP60

- 5-axis measurement

- RenAM 500Q

Editorial, News, and Products

-

5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

Renishaw Technology Reduces Metal AM Build Times

A new scanning algorithm for Renishaw’s RenAM 500 series of metal additive manufacturing systems enables the laser to fire while the recoater is moving, which over the build cycle can reduce total build time by up to 50% with no reduction in part quality.

-

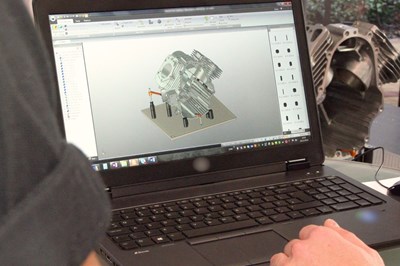

Renishaw Fixture-Modeling Software Streamlines Setup Process

The FixtureBuilder 3D software enables fast creation and documentation of advanced, CAD-based, metrology fixturing setups.

-

Renishaw AM System Features Detailed Build Insight

The RenAM 500 Ultra system features innovative optical, chamber and gas-flow design, and also adds new productivity-boosting Tempus technology and advanced process monitoring software.

-

FFG Celebrates Grand Opening of Technology Center

The event featured live demonstrations of CNC equipment and vertical/horizontal milling and turning solutions for high-speed, die/mold, heavy duty, multi-axis, multitasking and high-volume machining solutions across various FFG brands.

-

Takeaways From TASC

Across a range of technical presentations aimed at small and mid-sized job shops, the first-ever Automated Shop Conference (TASC) offered insights into several automated technologies, implementation strategies, shopfloor training tips, and even the untapped power of automated coolant delivery.

-

Renishaw Data Platform Promotes Connected Shop Floor

Westec 2023: Renishaw Central collects metrology, status and alarm data from connected devices across the shop floor.

-

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

-

The Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.

-

Renishaw Robotics Solutions Simplify Calibration, Maintenance

The RCS L-90, RCS T-90 and RCS P-series are designed to simplify robot set up, health checks and recovery of robotic applications following collisions.

-

Simulation and Tooling Secure High-Value Work

Simulation software and careful attention to tooling parameters have enabled Major Tool to take on ambitious projects with its complex machinery.

-

Renishaw Offers Self-Centering Scale Discs for Quick Setup

Centrum CSF40 scale discs are quicker and easier to install due to the specially designed flexures that act like springs to align the disc to the shaft.

-

Renishaw Offers High-Speed Comparative Gaging System

The Equator system enables high-speed scanning and rapid moves between features, while retaining stiffness that delivers point-to-point repeatability for accurate gaging.

-

Partial Automation Inspires Full Cobot Overhaul

Targeting two-to-four hours of nightly automation enables high-mix manufacturer Wagner Machine to radically boost its productivity past a single shift.

-

Renishaw’s Advanced Manufacturing Roadshow Makes Stop in Michigan

The event features presentations with metrology experts answering questions on the significant measurement challenges facing manufacturers, ranging from job shops to high-production environments.

-

OEM Moves From Automation Implementation to Refinement

Automating challenging parts for full-weekend automation requires substantial process refinements that can significantly boost throughput.

-

The Job Shop Is the First Half of the Business

By day, NTL Industries went from a lathe and a mill in a home garage to an 11-employee enterprise in under five years. By night, it tackles a new future.

-

Speedy Setups Secure a Quick-Turn Niche

A talent for live-tool lathe changeovers keeps Kustom Machining & Manufacturing’s customers coming back for more.

-

Focus on Throughput Empowers People and Machines

Lessons learned in robot-tending coordinate measuring machines (CMMs) translate well to a self-correcting multi-tasking machining process.

-

Renishaw Updates Blue Laser Measuring Technology

Renishaw's NC4+ Blue system features improved optics that are said to deliver significant improvements in tool measurement accuracy, ensuring components can be machined more accurately and efficiently.

-

Renishaw Partners With Verisurf, Expands CMM Software

With an emphasis on Verisurf’s CMM Programming and Inspection Suite, this agreement gives companies access to Renishaw’s REVO five‑axis measuring system and the Equator flexible gauging system.

-

Renishaw's Alignment System Precisely Measures Parallelism

The XK10 alignment laser system achieves precise adjustments to machine parallelism at a level that was previously impossible with traditional measurement techniques.

-

Probing for Setup and Lights-Out Machining — The One-Person Shop Episode #2

Automatic measurement on the machine tool speeds efficiency by day and safeguards capacity at night for a small machine shop.

-

DMC Adopts Renishaw's Central Data Platform

The Digital Manufacturing Centre is the first to officially adopt Renishaw’s new manufacturing connectivity and data platform, Renishaw Central, to streamline additive and subtractive manufacturing.

-

Renishaw Debuts High-Durability Fortis Absolute Encoders

Renishaw designed its non-contact Fortis encoders for maximum repeatability and durability, with a vibration-resistance rating of up to 30 g.

-

Starrett AVR-FOV 0.14X Provides Widest Yet AVR Field-of-View

Starrett’s AVR-FOV 0.14X features a 0.14 magnification lens with the widest-yet AVR field-of-view, and delivers measurements accurate to the micron level.

-

Renishaw's Free CARTO 4.2 Update Enhances XM-60

Renishaw’s CARTO 4.2 software suite provides new features for calibration equipment, notably extending the measurement range of the XM-60.

-

Resolute Encoders Improve RF Antenna Accuracy, Resolution

Renishaw and Pacific Antenna Systems have teamed up, using Resolute encoders to provide robust, accurate and versatile RF antennas.

-

Automated Part Setup Maximizes Machine Utilization for Additive Manufacturing

MSP recently worked with Renishaw PLC to automate part setup and improve productivity for 3T Additive Manufacturing Ltd., helping cut part setup time from 5 hours to 10 minutes.

-

Choosing the Best Abrasive Finishing Process for 3D Printed Parts

Studies have shown that abrasive finishing is flexible enough to finish 3D printed parts with complex geometries and difficult-to-machine materials, although the best process depends on a number of factors.

-

Drone Manufacturer Applies 3D Printing for More Efficient Engines

Cobra Aero's metal 3D printer has been running "practically non-stop" since it was purchased last year. Two major wins for this process.

-

OEMs and Job Shops See Metal Additive Manufacturing Differently

When should a machine shop consider production metal 3D printing? Part of the answer might be when that machine shop also does design. Cobra Aero is a small shop thriving with AM, because it’s also an OEM.

-

Renishaw Appoints New President

A 33-year industry veteran, Denis Zayia has worked for Renishaw since 1995.

-

Shop Hands Over Gear Deburring to a Robot

Manual deburring of gears was an odious task for many of Katsa’s machinists, which in turn created a bottleneck that caused delays. The solution: a custom robotic deburring cell from Flexmill relying on Renishaw’s RMP60 probe.

-

Renishaw, Sandvik Collaborate on Validating AM Materials

Since 2018, the two companies have worked together to develop process parameters for a range of Sandvik metal powders.

-

Verisurf Announces Software Compatibility with Renishaw Five-Axis Probe

Verisurf’s president and CEO explains that the development is part of the software company’s commitment to universal measurement device compatibility.

-

Product Spotlight: Measurement and Inspection

This month’s Modern Equipment Review Spotlight focuses on technologies for part measurement, tool setting and machine inspection.

-

5 Impressions of EMO 2019, from Automated to Autonomous Manufacturing

The robot show? Not quite that. But automation and the expectation of processes that can run unattended if needed are clearly core to manufacturing now.

-

Fast Part Inspection Enables Quick Turnaround

Renishaw probes, used both on and off the machine tool, helped Tridan Engineering turn a Rally car part in just 17 days. It previously would’ve taken months to complete and inspect.

-

Mitsubishi Electric's Interactive Cycle Insertion Screens Incorporate Renishaw GoProbe Macros

Mitsubishi Electric Automation Interactive Cycle Insertion screens on its M8 series of CNCs are designed to be used with Renishaw’s GoProbe macros.

-

LK Metrology's Altera Scantek 5 CMM Gathers 4,000 Data Points per Sec.

Coupled with Renishaw’s Revo-2 multi-sensor scanning system, LK Metrology’s Altera Scantek 5 coordinate measuring machine (CMM) performs five-axis inspection for dimensional accuracy and surface finish.

-

Machining Demonstration Shows the Digital-Twin Concept in Action

A demonstration at IMTS 2018 showed that all of the pieces to meet the “Grand Challenge” are now in place, making so-called digital-twin manufacturing feasible for shops looking to streamline production of complex workpieces.

-

Metrology Technology Presented as "Smart Factory" Solutions

Eastec 2019: Renishaw is highlighting a range of its products as part of a “smart factory” strategy, focusing on metrology.

-

Metrology Fixture Range Gains ¼ 20 Imperial Thread Size

Renishaw has added a ¼ 20 imperial thread size to its existing metrology fixtures product range.

-

How Is Digitalization Affecting the Manufacturing Supply Chain?

Leaders across the supply chain offered their thoughts during a recent panel presentation.

-

Renishaw, Altair Deepen Partnership for Additive Design, Manufacturing

The two teams will offer joint seminars, workshops and training events that demonstrate metal AM production from powder to part, with emphasis placed on throughput and machine productivity.

-

News of Note: October 2018

The NTMA appoints a new president, Röhm acquires Master WorkHolding, Renishaw opens new demo center and more industry news.

-

Italian Machining Technology at BI-MU 2018

The 2018 edition of the Italian machine tool trade show emphasized start-ups, additive manufacturing and the automotive industry.

-

Software Update Enhances Capabilities of Rotary-Axis Calibrators

Renishaw’s Carto 3.0 software for its XR20-W rotary axis calibrator enables users to quickly capture and analyze machine performance data from rotary axes.

-

Renishaw Opens Additive Manufacturing Demo Center in California

Situated within Ibex Engineering’s headquarters, the center allows visitors to explore, interact with and use Renishaw’s latest metal additive manufacturing (AM) systems.

-

Shop Works to get the Most Out of Its Five-Axis Capabilities

Vertical machining centers with rotary tables helped this Indiana job shop set itself apart, but specific machine features and additional equipment have helped it use them more efficiently to grow its business.

-

Managing Risk Is This Shop’s Bold Strategy

Flying S routinely makes bold moves in how it processes machined parts and pursues business growth. This boldness comes from carefully minimizing risks.

-

XM-600 System Enables Faster and Easier CMM Error Mapping

Renishaw's newly launched XM-600 laser measurement system offers enhanced capability to connect directly with Renishaw's range of UCC CMM controllers.

-

Revo SFP2: A CMM Measurement Revolution

The Revo multi-sensor system enables you to switch between scanning and surface finish measurement.

-

Ultra-Fast Probing for Workpiece Setup, Surface Condition and Form Monitoring

The Sprint system with SupaScan is an easy-to-use touch-trigger and on-machine scanning measurement system.

-

Measure 6 Degrees of Freedom from a Single Setup

The XM-60 is a powerful diagnostic laser measurement system capable of measuring errors in linear, pitch, yaw, roll, horizontal and vertical straightness measurements simultaneously from a single setup.

-

Hopper Provides Batch-to-Batch Powder Management for 3D Printing

IMTS 2018: The PowderTrace hopper from Renishaw and LPW Technology is an external powder silo option for the RenAM 500 series of AM systems.

-

Ultra-High Productivity Multi-Laser AM System

The RenAM 500Q is Renishaw’s multi-laser additive manufacturing (AM) system.

-

The Equator 500 Gaging System

The Equator system is a flexible gage, designed to provide speed, repeatability and ease of use for manual or automated applications, which is why hundreds of manufacturers worldwide are replacing their current gaging method with Equator systems.

-

Metal AM System's Four Lasers Increase Productivity

To improve additive manufacturing productivity and lower cost per part, Renishaw has launched the RenAM 500Q.

-

Benefits of Scanning Touch Probes for Setups

Touch-trigger probes are commonly used to speed and simplify setups for new jobs, but scanning touch probes are valuable for these duties, too.

-

Apps Simplify Use of Tool Probes, Tool Setters

Renishaw has developed the GoProbe and Trigger Logic smartphone apps for users of its machine tool probing hardware.

-

In Hogout Machining, the CAD File Becomes Critical

To serve customers by helping them bypass casting, this shop first needs a close-enough relationship with the customer that it can count on getting good CAD data. Here is why.

-

How Part Data Control Will Expand and Simplify the Supply Chain

Digital rights management for manufactured part files will enable OEMs to enforce manufacturing requirements at a distance, as an alternative to in-person certification of suppliers.

-

What Does It Take to Succeed at Machining Hogouts?

Beyond the machining capacity, other important factors relate to the people and the understanding of the process.

-

Four-Laser Additive System Improves Productivity

The company is also introducing process-monitoring and high-temperature additive manufacturing technology.

-

The Link Between Gaging and Tool Cost Savings

New software delivers the next step for Renishaw’s programmable gaging system: a mechanism for changing cutting tools when they are truly at the end of their life, not after an arbitrary number of pieces have been run.

-

Meeting the Machining Challenges of Additive Manufacturing

You can 3D print the part, but can you finish it? Here is how to overcome the challenge of part deflection in the machining of lightweight, complex AM parts.

-

What We Learned at Westec 2017

Westec offered a useful mix of emerging technology and practical applications. This slide show reflects this mix in its eclectic coverage of what exhibitors had to offer.

-

How to Anticipate Machining Errors before Parts Are Scrapped in QA

In L&S Machine's system for data-driven manufacturing, the data describe a good day.

-

Flexible Gage Software Integrates with CNC Machine Tools

EMO 2017: Renishaw will exhibit its software for the Equator flexible gauge, which allows users to fully integrate the system with CNC machine tools, its contact scanning system for CNC machine tools, its on-machine and mobile apps which are designed to simplify the use of machine tool probing, an enhanced non-contact tool setter for machining centers, a multi-probe optical interface system, a surface finish probe for coordinate measuring machines, and software that enhances the functionality of Renishaw’s XM-60 multi-axis calibration system.

-

On-Machine Scanning Probes for Speedier Setups

Renishaw introduces new on-machine, touch-probe scanning technology to enable faster workpiece setup and inspection cycles.

-

Gage Software Connects to CNC, Automates Tool Offset Updates

The Renishaw Equator flexible gage is now offered with intelligent process control (IPC) software, providing the functionality to fully automate tool offset updates in CNC manufacturing processes.

-

Renishaw Engineer among Top 50 Women in Engineering in 2017

Lucy Ackland has worked on developing the company’s RenAM 500M metal additive machine, and continues to lead outreach to young girls about engineering careers to narrow the United Kingdom’s gender gap in the field.

-

Hiring, Training and Supporting the Workforce in School and on the Job

Virginia’s Rolls-Royce Crosspointe plant shares its strategies for attracting, hiring and supporting its workers, while Danville Community College excels with its integrated machining education model.

-

One Setup Unrolls Six Linear Errors

Consisting of only two components, this linear axis calibration device measures error in all six degrees of freedom—including roll—directly and in real time.

-

Multi-Axis Calibrator Captures Angular, Linear, Straightness Errors

Renishaw’s XM-60 multi-axis calibrator can measure six degrees of freedom from a single setup and in any orientation for linear axes.

-

Renishaw Prepares for Growth in North America with New Facility

The company’s new North American headquarters will also include an Additive Manufacturing Solutions Center.

-

Three Design Strategies for Additive Manufacturing

It’s possible to reproduce existing designs via metal additive manufacturing. But the greatest benefits come from designing intentionally with additive in mind.

-

Reducing the Weight of a Robot Actuator

A metal additive manufacturing process reduced the weight of a hydraulic actuator, leading to a better performing component.

-

Can Additive Manufacturing Increase Milling Feed Rates?

With PCD tooling, yes it can. The diamond cutting edges demand a large number of flutes to realize their full effectiveness. Traditional methods for making cutter bodies limit the number of flutes, but 3D printing is delivering tools with higher flute density and other enhancements as well.

-

Manufacturing News of Note: November 2016

A Brazilian student wins an advanced materials contest, Local Motors launches an SaaS division, Airbus certifies an additive material from Stratasys and other industry news.

-

Renishaw’s Dedicated Facility Makes Custom Additive Medical Parts

The Healthcare Center of Excellence is located adjacent to the company’s South Wales site, where it makes its additive equipment.

-

When a Turn-Mill Doesn’t Turn

LeanWerks uses innovative probing, tooling and workholding strategies to enable its turn-mill to machine castings complete, in effect turning it into a five-axis machining center.

-

Renishaw Makes Senior Management Changes in Response to U.S. Expansion

The changes include upper-management promotions and appointments as the company plans for new facilities opening in 2017.

-

July 2016 Product Spotlight Slideshow: Measurement and Inspection

This month’s Modern Equipment Review Spotlight focuses on equipment and software for measurement and inspection.

-

Simplify Setups with 3D-Modeling Software

New software allows setups to be created onscreen, making it easier to determine the optimal designs and the quickest setups.

-

“Pay As You Go” Probing

This part- and tool-setting probing system minimizes upfront costs by using a “pay as you go” model, whereby users purchase a six-month credit token that enables unlimited use of the system during that period.

-

Don’t Sweat the Setup: Probing the Position of Complex Workpieces

This manufacturer uses a software tool to tailor the machining program to the location and orientation of each contoured part.

-

Video: Does Metal Additive Manufacturing Compete with Machining?

In an interview during the Additive Manufacturing Conference, one expert says no—in fact, they’re complementary.

-

Closed-Loop Gear Production

A familiar concept is now gaining serious traction, enabling manufacturers to develop closed-loop cells that automatically match the finished product to design concept goals.

-

How Renishaw Is Lowering Barriers to Additive Manufacturing

The company wants to help manufacturers prove out designs and processes for part production via additive manufacturing.

-

Vision Probe for CMM System Handles Sheet Metal, Small Holes

Renishaw has expanded its Revo five-axis measurement system for use on coordinate measuring machines (CMMs), with an RVP vision measurement probe.

-

Can a CNC M-Code Accelerate Laser Calibration?

A metrology technology supplier describes a technique for significantly reducing the downtime to calibrate large machines.

-

Visiting Renishaw in the UK

The unveiling of Renishaw’s new 153,000-square-foot Innovation Center gave me a good opportunity to visit a company in the UK that I’ve known for years.

-

Houstex 2015 Preview Slideshow

Click through the slideshow to see a selection of technologies to be displayed at Houstex in advance of the February 24-26 trade show.

-

Laser Encoder Feedback for 40-Meter Wing Parts

Large machine travels, long machining cycles and changing aircraft manufacturing precision demands necessitated a non-contact approach to machine-tool position feedback.

-

Raising the Bar with Ballbar Testing

Few manufacturing companies rely on ballbar testing to maintain machine tool accuracy as thoroughly as Silfex. Now, advanced training and a move to a Renishaw QC20-W wireless system have enabled the company to take the benefits of ballbar testing to a higher level.

-

Discover More—And I Did

The time I spent at the Discover More with Mazak Midwest event in Schaumburg, Ill. was designed to help attendees discover new tools and techniques for staying ahead of the manufacturing curve. Here are four good ideas that caught my attention.

-

3D-Printed Titanium Bike Frame Manufactured for Empire Cycles

An additive manufacturing technology supplier collaborates with a British bicycle company to create what the two companies say is the world’s first 3D-printed metal bike frame.

-

Measurement Technology Transcends Limitations

One metrology equipment supplier says its laser systems address common difficulties with noncontact measurement, while another touts a product that enables measuring surface finish on CMMs.

-

Videos Showcase SFP1 Probe

These two videos showcase some of the technology behind the SFP1 surface finish probe option for Renishaw's Revo five-axis measuring head.

-

Probe Enables Finish Measurement on CMMs

The SFP1 probe uses technology incorporated in Renishaw’s five-axis Revo measuring head to facilitate surface finish measurement on CMMs.

-

A Tidy Turning Cell

This compact cell offers automated turning and inspection for extended periods of unattended operation.

-

The Big Step Up

A small shop added two new machines, each of which is more advanced than any of the previous machine tools the company has used. One of the co-owners committed to the work of bringing both of these machines fully into service. Here is the shop’s experience so far.

-

Tidy Machining Cell

A compact cell designed by Gosiger Automation demonstrates the advantages of automated turning and inspection for long stretches of unattended operation.

-

Probe Option for CMMs

Renishaw’s SFP1 probe option for the Revo five-axis measurement system enables surface finish inspection to be integrated within coordinate measurement routines.

-

More Demanding Than Production

The challenges of prototyping have dramatically increased. This company reinvented itself to specialize in the tight-leadtime process development that prototyping now entails.

-

Multiple Tool Setting and Inspection Probing for Machine Tools

Renishaw's RMI-Q multiple-probe radio transmission system uses a single radio receiver for tool-setting probe and spindle-mounted touch probe installations.

-

Selective Laser Melting Makes Parts Directly from 3D CAD

The additive manufacturing process used in Renishaw’s SLM125 and SLM250 selective laser melting uses a high-powered fiber laser to produce fully dense metal parts direct from 3D CAD.

-

Wireless Ballbar Speeds Medical Machine Testing

The QC20-W wireless ballbar from Renishaw enables this precision-machined medical device manufacturer to perform faster, more convenient CNC machine capability tests and produce a representative measurement of volumetric positioning accuracy.

-

PC-Based Probing Software for Machining Centers

Renishaw’s Productivity+ version 1.90 integrates measurement and process control functionality into CNC machining programs.

-

Cycle Efficiency

Automated machining processes enable this maker of high-performance mountain bike parts to manufacture efficiently with minimal staff.

-

Renishaw Acquires MTT

The metrology company’s move suggests confidence in additive manufacturing.

-

New Idea in Shopfloor Gaging

In many manufacturing facilities, production measurement and programmable measurement are two separate things. Read how one company’s new product represents a new idea in gaging.

-

Inspection System Brings Programmability to Shopfloor Gaging

Gaging device extends the reach of the CMM out to the production floor, and provides an alternative to dedicated gaging.

-

Probe Has Right Touch for Five-Axis Aerospace Parts

On-machine measurement is critical at this aerospace manufacturer, which needs to ensure that features of already high-value parts are within specification before performing additional operations. With the RMP600 strain-gage probe from Renishaw, the company has eliminated the delays that come with measuring on a true CMM.

-

Last Glance at IMTS 2010

It would be impossible to cover all of the key exhibitors at IMTS 2010—even if every booth got merely a quick glance. However, the editors of MMS did get glimpses of some interesting technologies exhibited at the show...

-

Five-Axis Head for Inspection on CMMs Increases Throughput

Utilizing technology developed for its Revo measurement system, Renishaw says its PH20 probe head offers “head touches” for rapid touch-trigger measurement and fast, infinite, five-axis positioning for optimal feature access.

-

Five-Axis Head for Touch-Trigger Inspection on CMMs

Utilizing technology developed for its Revo measurement system, Renishaw says its PH20 probe head offers “head touches” for rapid touch-trigger measurement and fast, infinite, five-axis positioning for optimal feature access.

-

Wireless Ball Bar Has Volumetric Testing Capability

The QC20-W ball bar features a linear sensor and Bluetooth wireless technology for greater ease of use and enhanced durability, the company says.

-

It Takes Firm Resolution To Master The Micro

This shop’s experience of successfully machining a micro aneurysm clip in silicon nitride ceramic points out the need to have CAD, CAM and CNC capability at high resolution—plus the commitment to pull it all together.

-

How Stylus Choice Affects CMM Accuracy

Measurement uncertainty and inconsistency can result when an improper CMM stylus is chosen. A metrology products manufacturer details four aspects of stylus choice that can impact overall CMM accuracy.

-

How to Improve Machining Center Accuracy

Accuracy is not just inherent to the machine—it also depends on how the machine is used. Try these techniques to let a new or existing CNC machining center achieve its potential precision.

-

Turning On A Machining Center

VIDEO. Part of Renishaw’s automated production process, this turning operation uses tools affixed to the machining center’s table while the workpiece is mounted in the spindle.

-

Video: Automatic Part Verification Through Reference Comparison

The machining center in this automated production process inspects its own work and updates its own positioning. Probing a known, traceable reference makes this possible.

-

Can A Machining Center Be Used As A CMM?

One manufacturer in need of a shop-rugged CMM wants to use a probe-equipped VMC for precisely this purpose. The shop asked probing expert Renishaw about this idea. Here is the response.

-

Probing Beyond Prismatic

This manufacturer has used on-machine probing to help automate setups and maintain process control for prismatic parts produced on VMCs for years. The metrology products maker recently implemented probing strategies that let it achieve similar results on its turn-mills and Swiss-types. The smaller, more economical batch sizes these machines now produce are better aligned with true production requirements.

-

Get Better Before You Get Bigger

Rather than making a major new machine tool purchase just yet, this shop is finding additional capacity on the equipment it already has. What once was a vertical machining center will become a flexible automated production center for unattended machining.

-

RAMTIC System Still Ticking

When it first appeared in the early 1990s, RAMTIC (Renishaw’s Automated Milling, Turning and Inspection Center) pioneered the use of portable carrousels for palletized workpieces and the use of artifacts, or master components, by which a machine tool could check its own dimensional calibration. This innovative approach to process control is still highly effective as applied in the company’s most advanced machine shop, which opened in 2006. Carrousels and artifacts are very much a part of this new shop’s remarkable success.

-

Compliant Machining Of Composite Wings

Bell Helicopter created a systematic, scripted process to machine composite wing skins and structural components for the V-22 Osprey vertical takeoff aircraft. Custom software ensures there is no deviation from the script.

-

Under One Roof

In bringing multiple manufacturing processes in-house, this medical shop parallels its customers' efforts to be one-stop sources for hospital equipment.

-

Move The Program Instead Of The Part

A complex five-axis part with hard-to-reach datums is machined in two setups instead of eight, thanks to a process that rewrites the tool paths to match the part's position.

-

Thinking Big

This shop specifies large machine tools for the machining possibilities of the future. To prepare for the feed rates the shop expects to use one day, the latest large gantry mills apply linear motors on all three linear axes.

-

Revving Up The CMM

High speed, five-axis scanning promises to give throughput on coordinate measuring machines a big boost. Entire manufacturing strategies may be up for rethinking as a result.

-

System Takes Guesswork Out Of Diagnosing Problems

Rockwell Automation Power Systems (Greenville, South Carolina) specializes in technologies and services for optimizing power transmission performance and productivity.

-

Release The Potential Of Your Machine Tool

Probing can improve OEE in many different ways throughout the machining cycle. (Sponsored Content)

-

Move Parts - Don't Move Production

Robotic automation can make manufacturing in North America the most profitable choice. (Sponsored Content)

-

Automation For Information

There is a wealth of information already in the shop. Here is how to profit from it. (Sponsored Content)

-

A Manager's Guide to Overall Equipment Effectiveness (OEE)

Under current economic conditions, severe global competition and postponement of new equipment purchases are causing business executives to be sensitive about all aspects of manufacturing operational costs. In this environment, it pays to consider both creative and proven methods that manufacturers can use to bring their product to market at minimum cost. 'Overall Equipment Effectiveness' (OEE) is a method that meets this objective. (Sponsored Content)

-

Keeping Accuracy Within Reach

Part quality is at risk if a machining center cannot hold tolerances at the farthest reaches of its work envelope. This makes volumetric accuracy a key indicator of a machine's performance. One machine tool builder discusses the implications.

-

CAM Software For Probing

Software for creating probing routines off-line promises to make machine tool probing easier to use. As a few examples show, different software providers look at this off-line programming in different ways.

-

Faster Inspection On Existing CMMs

Software that adjusts for dynamic error lets a CMM inspect at higher rates without losing precision.

-

Humility, Inc.

This shop has capabilities similar to others. It hires employees who have no experience. What sets the shop apart and accounts for its success is an unusual attitude of service toward customers.

-

The Technology Of Lean Machining

This plant makes different choices for its machining cells depending on whether the parts to be machined there are known or unknown.

-

Using The Machine Tool As A Gage

On-machine inspection probing keeps jet engine production flying.

-

Winning The Door Prize

The accuracy of this shop's five-axis gantry-type profiler helped it land the job of machining the engine-bay doors for the F/A-22.

-

Racing Team Shifts Into Reverse Engineering

When the Joe Gibbs Racing team went shopping for a reverse engineering system five years ago, it looked at a variety of technologies. But the team decided to put this on-machine scanning system in the driver's seat of its reverse engineering program.

-

Retrofitted Laser-Scale Systems Improve Linear Accuracy Of Gantry Mills

When aerospace machining specialist Alson Manufacturing of Compton, California, produced its first parts more than 30 years ago, allowable tolerances on a 160-inch part might have been 0.030 to 0.040 inch. Today, thanks to an industry-wide narrowing of tolerances, that same part has to be machined to within ±0.004 inch of the printed specification.

-

Probing For Process Improvement

Advances in machine accuracy and probing technology make on-machine inspection a powerful tool for automating and speeding part processing.

-

Under Control

This small-parts machining operation combines superbly automated workholding and handling with total machining process management.