Finishing A Pocket Floor In Titanium

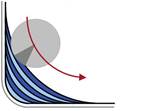

Machining animation from Boeing illustrates effective techniques for titanium workpieces. This simulation also shows finishing of the floor of the pocket.

Like the previous simulation in this series, this machining simulation provided by Boeing Research and Technology (using CGTech software) shows roughing followed by material removal from the corners prior to finishing. The finishing of the walls is performed with fast passes at successive layers.

This simulation also shows finishing of the floor of the pocket. Note how the tool radiates out from the center of the pocket to the wall. This keeps unmachined stock always adjacent to the cut for support. No section of the floor is ever touched again after it has been machined once.

Find details in the articles at right. Or, see other videos in this series:

1. Video: Finishing Walls In Titanium

2. Video: Finishing A Pocket Floor In Titanium

3. Video: Plunge-And-Sweep For Finishing Corners

Related Content

-

"Crazy" Tools from Mikron Expand Capabilities

Despite past challenges of the pandemic, Mikron Tool's R&D department runs at full speed, developing efficient machining of demanding materials in the micron range.

-

10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

-

How to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)