Milling with Air

... not to mention grinding with air. Thanks to high speed spindles powered by shop air, this job shop expands the work its VMCs can do.

Video footage: air-driven spindle

Bryan Machine Service has a jig grinder, but the machine doesn’t see as much activity as it once did. One recurring part number illustrates why. The part has a series of holes, two of which demand grinding. In the past, after drilling on one of its Haas machining centers, this Huntington, Indiana job shop would take the part to its grinding room to do the jig grinding work.

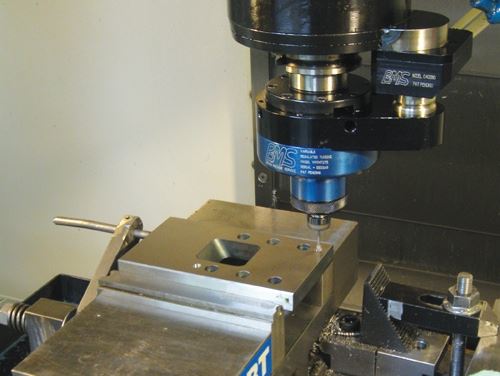

Now, the part remains on the machining center. This same machine that does the drilling can do the grinding as well. Nothing about the machine has changed, except for the addition of one accessory—a spindle driven by shop air. The lightweight 40,000-rpm spindle fits into the machine’s main spindle just like a toolholder.

Bryan Machine has six VMCs. All from Haas, they range in size from Mini Mill to VF-6, and through the addition of high speed air spindles, all have become more versatile. In addition to jig grinding, the shop uses the air spindles for profile grinding, engraving, graphite milling and machining with small tools. In each case, the spindle saves cost by eliminating a setup, and in some cases the spindle expands the range of work that the shop is able to perform.

Owner Steve Bryan invented the spindle design himself. His shop produces these spindles; selling them is a small side business. He says many CNC machining centers today, even low-cost ones, are already capable of the precise interpolated moves and fine-detail tool paths that make grinding or small-tool milling practical. All that’s needed is the higher spindle speed. The discovery he made about 12 years ago—when he first bought an air-powered spindle—is that this accessory offers a low-cost way to realize more of the capability that modern VMCs can deliver.

3D Machining

Ironically, it was software that first led the shop to use this hardware accessory. When Bryan Machine began to use sophisticated CAM software, the ability to perform accurate machining of complex 3D surfaces made it possible for the shop to win graphite electrode milling work from a nearby manufacturer of molded rubber parts. A low-power spindle, driven by shop air, provided a means for the shop to machine graphite efficiently on its existing machines rather than buying a dedicated electrode mill.

However, Mr. Bryan found shortcomings with that initial air-powered spindle. One was the connection to the shop air supply. The spindle had to be loaded by hand into the main spindle because the air connection was a hose that had to be affixed manually. A more significant limitation was that the spindle had only one speed. The shop bought a 20,000-rpm air spindle, only to discover that one job would require 30,000 rpm.

Mr. Bryan, a tinkerer, decided to develop his own design. Among his requirements was that the spindle had to be speed-adjustable, as well as shorter than the shop’s existing air spindle for greater rigidity. A new spindle also had to be capable of being changed in and out by the machine’s toolchanger, without the air connection getting in the way.

Today, that toolchanger compatibility is accomplished with a stationary air manifold installed on the machine. An M-code controlled solenoid engages the manifold with the spindle. The rigidity and adjustability objectives were both met, too. The air spindle unit offers variable speed ranging from 15,000 to 40,000 rpm. At 20,000 rpm, the unit delivers about 1.5 horsepower.

Low-end torque is one advantage of the high speed spindle, Mr. Bryan says. Not the low-end torque of the air spindle—but the torque of the standard spindle on the machine. If a high speed spindle is simply an accessory, he points out, then the machine’s own original low speed capabilities remain available. One of Bryan’s machining centers is 50-taper. Having an air-powered spindle in the tool magazine means this machine can do both heavy milling of steel and fine grinding of the part surfaces—not just in a single setup, but in a single, unassisted NC cycle that swaps these capabilities using the toolchanger.

Electrode Mill

Recently, the shop did decide to buy a separate machining center for electrodes. However, it bought a standard-speed machine—a Haas Mini Mill equipped with a standard 6,000-rpm spindle. Mr. Bryan says the spindle is the only thing about this machine that might be considered “low speed.”

Specifically, the CNC is equipped for high speed machining. Its capabilities include look-ahead for holding complex tool paths at high programmed feed rates. With this CNC, the machine can take advantage of the fast moves in graphite that a high spindle speed would make possible. It just needed the high spindle speed.

Mr. Bryan finds this accessorized approach to high speed milling to be a more effective solution for the shop’s graphite work than a dedicated high speed machining center would be. The shop’s new Mini Mill does not have to be committed to high speed milling, he says. Whenever necessary, the shop has the option of simply leaving the air-powered spindle in the carousel and running a job that takes advantage of low-end torque.

Related Content

Tool and Die Shop Discovers New Opportunities With First CNC Machine

In a shop that stamps millions of parts per year, the arrival of a CNC machining center is opening new pathways for production and business.

Read MoreStars Slowly Align for Small Shop Merger

RPM Tool’s seemingly overnight expansion from a five-person machine shop to an almost 30-employee production business involved over a year and a half of planning.

Read MoreHexagon Acquires TST Tooling Software Technology

Hexagon acquires TST Tooling Software Technology, a distributor of VISI, Hexagon’s CAD/CAM software for the mold and die sector, and PEPS CAM software.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)