Top Shops 2011: Hyper-Tech

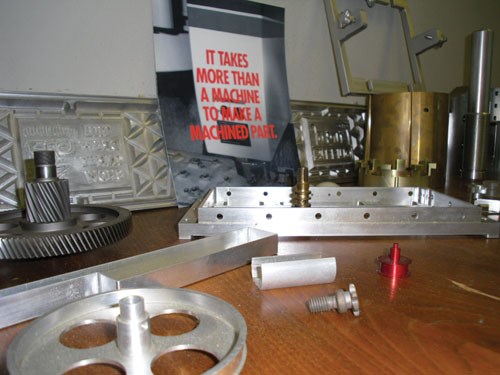

This shop uses CNC turning, milling, gear cutting, ID and OD grinding, honing and broaching to be a done-in-one supplier of machined parts.

More than an ordinary machine shop, Hyper-Tech offers turning, milling, gear cutting, ID and OD grinding, honing and broaching all on the latest CNC equipment. This enables it to maintain high quality standards throughout the entire manufacturing process.

Hyper-Tech is dedicated to producing parts that meet today’s tough acceptance standards, and its quality control system is designed to meet or exceed most aerospace requirements. Its machinists have gone through rigorous journeyman training. They go back to school for continuing education on the latest technology, including CNC and CAM programming and the newest quality-control methods. The shop designs and manufactures mechanical assemblies, prototypes and runs production-volume lots. It works with a vast array of metals from aluminum to zinc as well as plastics.

Related Content

-

Building a Better Business: Lessons for Machine Shops From an Unexpected Source

Learning how to be a great manufacturer by listening to the insights of a different industry, homebuilding (which perhaps is not so different after all).

-

Niche Work If You Can Get It: A CNC Machine Shop Crafts Its Own Destiny

The latest innovations in metalworking aren’t always related to CNC automation or robotics. For Rosenberger North America, a 2022 Top Shops Honoree, it is the company’s niche processes that create the biggest successes.

-

Top Shop Builds Upon Employee Ownership for Future Success

In its quest to become the Fox Valley’s best-in-class employer, A to Z Machine has adopted an ESOP, expanded benefits and invested in apprenticeships.

.jpg;width=70;height=70;mode=crop)