Why Y?

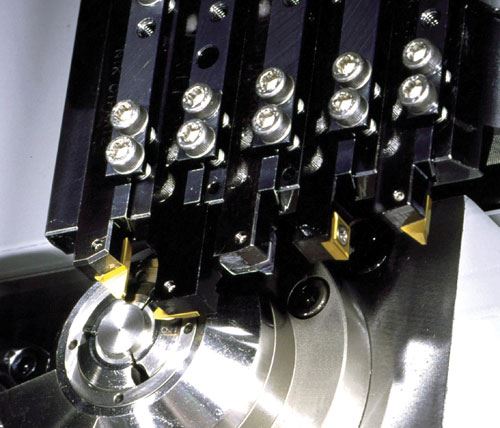

This toolholder takes advantage of a Swiss-type’s Y-axis motion to approach and engage the barstock from the side, which helps prevent “bird nesting.”

Better chip control on Swiss-type lathes, for one. “Y” refers to the Y-axis/gang-tool-slide motion these machines use primarily to bring a different tool into position for a different turning operation. Once the new tool is positioned, the X axis moves it straight down into the top of the barstock to perform the operation.

That’s how it works using conventional tools, anyway. However, depending on the workpiece material, chip control can be an issue with this traditional approach. This spurred NTK Cutting Tools to develop its Y-Axis Control toolholder. Instead of approaching the barstock from the top, it takes advantage of the Swiss-type’s Y-axis motion to approach and engage the barstock from the side. Aided by gravity, the downward-facing chipbreaker on the tool’s insert directs chips down and away from the cutting zone. This helps prevent “bird nesting” around the workpiece during front-turning, back-turning and grooving operations. Plus, the tool’s rigid design is said to minimize vibration to ensure precise machining operations and quality surface finishes.

Although the company admits the Y-Axis Control tools look chunky (that’s the company’s word, not mine), each occupies only one slot on a gang-tool slide. Because of their bulkier design, though, only one or two tools can be installed on the slide, and a pair of them can’t be located side-by-side. Barstock size can vary depending on the tool’s position on the slide as well as the difference in overhang from a conventional X-axis tool (Y-Axis Control tools are slightly longer). The tools accept 35- and 55-degree ISO inserts.

Related Content

-

GenSwiss Releases Redesigned Toolholding System

Its GenQuick quickchange ER system for Swiss-type CNC machines and precision machining equipment has been updated.

-

Quick-Change Collet Chuck Doubles as Mandrel

The hybrid Comot-AZ quick-change collet chuck from SMW Autoblok can be used for OD machining and can be transformed into an expanding mandrel for ID clamping using the EMX series.

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)