Five-Axis

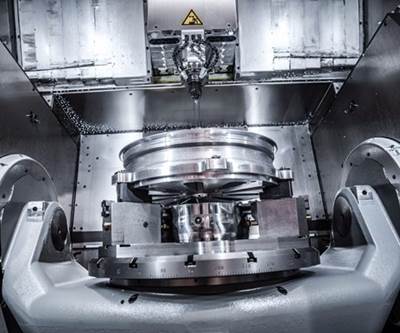

When Buying a Five-Axis Machine, Bigger Isn't Always Better

For trunnion-type five-axis machine tools, workpiece size will have an impact on what size machine you should buy.

Read MoreFive-Axis Machine’s Water-Cooled Traveling Column Increases Rigidity

Zimmermann is introducing the FZH400 five-axis machining center with a water-cooled traveling column.

Read MoreSW North America Opens Manufacturing Facility

The Michigan facility will help the company grow its presence in the automotive market.

Read MoreHeller Hires New VP of Sales for North America

Stephen Pegram will use his experience in the machine tool industry to grow the company’s special machine tool business.

Read MoreAluminum Material Removal Rate New World Record?

Sweden’s Modig Machine Tool says it has achieved the world’s highest material removal rate in aerospace-grade aluminum at 1,001 cubic inches per minute.

Read MoreManufacturing News of Note: November 2017

Acquiring a cutting tool manufacturer, growing apprenticeships in the United States and other industry news.

Read MoreOne Five-Axis Process, 10 Elements of Automation

The new five-axis machine at Phoenix Proto has a pallet pool with loading system, but there are many other less obvious elements of automation in this precision mold-machining process that are just as essential.

Read MoreThe YouTube Apprentice

Inspired by social media and unencumbered by preconceived notions about how to machine, this shop owner plunged confidently into five-axis aerospace work.

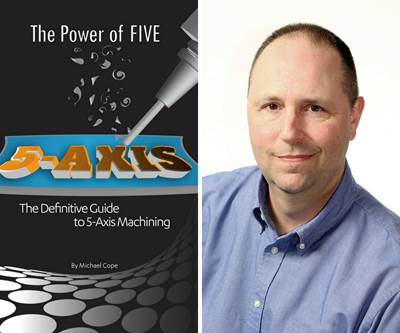

Read MoreHurco Engineer Publishes Book on Five-Sided Machining

For Michael Cope, the book is a chance to reach machinists and shop owners about the advantages of five-axis machining, which he sees as the industry’s future.

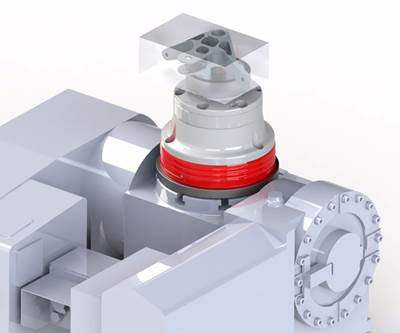

Read MorePartners in THINC Winter Showcase to Demonstrate Five-Axis Setup

The demonstration is intended to benefit shops that need to do five-axis work but don’t want to or need to incur the price of a dedicated five-axis machine tool.

Read More

.jpg;maxWidth=300;quality=90)