Aerospace

Rego-Fix Appoints New Global Aerospace Specialist

Sherman D’Souza will provide global customers with access to Rego-Fix research, development and technical support teams to create and supply toolholding solutions.

Read MoreIncreasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

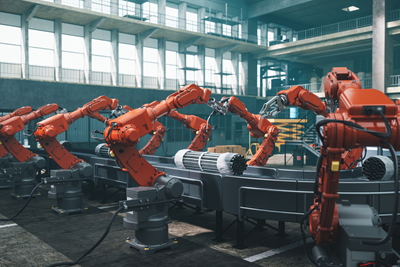

Read MoreMachine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read MoreSolar Atmospheres Receives Northrop Grumman Approval for South Carolina Facility

All five Solar Atmospheres facilities are now an option for customers with Northrop Grumman requirements for vacuum heat treating.

Read MoreSolar Atmosphere Receives Boeing Approval for Vacuum Oil Quenching

The approval was granted for oil quenching of alloy steels in the company’s new furnace, the Neo.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read More10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

Read More

.png;maxWidth=300;quality=90)