Cutting Tools

Kennametal Introduces FBX Drill for Aerospace Machining

The FBX drill from Kennametal is designed for flat-bottom drilling for structural aerospace parts, combining advantages from a flat-bottom drill and a Z-axis plunge mill.

Read MoreIngersoll Introduces Superturnz Inserts

Superturnz, a multi-directional turning system that uses the front and back cutting edge of a four-corner insert, is now available from Ingersoll.

Read MoreGreenleaf Introduces Xsytin-360 End Mills

Greenleaf's Xsytin-360 solid ceramic end mills offer high material removal rates and increased productivity, according to the company.

Read MoreIs It Time to Reconsider Regrinding?

The advance of automation makes in-house cutting tool regrinding more accessible. An automated measurement cycle adjusts the tool path in grinding operations to make regrinding simpler to program and easier to automate.

Read MoreTungBore-Mini Boring Toolholders Improve Chip Evacuation

Tungaloy has released boring toolholders for its TungBore-Mini line. The company says these toolholders maximize chip evacuation for small-diameter boring contexts.

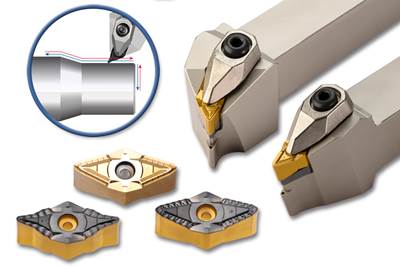

Read MoreShifting Toward Preparedness and Flexibility with Turning Tool for Steel

The pandemic has taught manufacturers to reevaluate their preparedness for unexpected and drastic market disruptions. A practical example from a cutting tool manufacturer may show the way.

Read MoreTungaloy AH9130 Extends Life in ISO P, M and K Applications

Tungaloy’s AH9130 insert grade for its DrillForce-Meister line of exchangeable-head drills enhances tool life and wear-pattern predictability for ISO P, M and K hole-making applications.

Read MorePalmgren Releases Durable, Heavy-Duty Bench Grinders

Palmgren’s heavy-duty bench grinder provides what the company says are longer duty cycles under load and less speed degradation than competing products.

Read MoreEMAG Acquires Samputensili

EMAG has acquired Samputensili Machine Tools and Samputensili CLC, planning to merge them into EMAG SU Srl.

Read MoreHorn Tooling Boosts Pipe and Coupling Machining Performance

Horn USA has developed a variety of different tooling solutions to assist end users and manufacturers of machine tools in the pipe and coupling production market.

Read More

.png;maxWidth=300;quality=90)