Data-Driven Manufacturing

Protecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreManufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

Read MoreLeveraging Data to Drive Manufacturing Innovation

Global manufacturer Fictiv is rapidly expanding its use of data and artificial intelligence to help manufacturers wade through process variables and production strategies. With the release of a new AI platform for material selection, Fictive CEO Dave Evans talks about how the company is leveraging data to unlock creative problem solving for manufacturers.

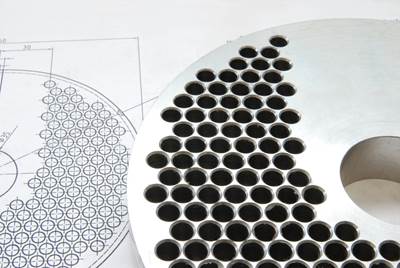

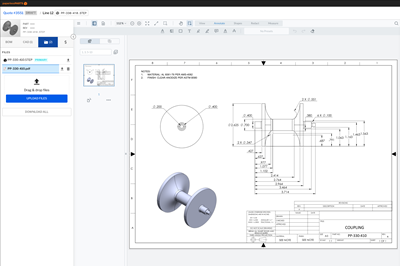

Read MorePaperless Parts Software Streamlines Quoting Process

The software streamlines repetitive, error-prone tasks associated with request for quote intake and prep work, allowing estimators to focus on high-value activities.

Read MoreGF Machining Solutions Platform Enables Remote Troubleshooting

The My rConnect provides a virtual link between a machine and the company’s service and support team, often eliminating the need for a technician to travel to a customer’s shop.

Read MoreABB Software Platform Streamlines Data Management

OptiFact is designed to speed up diagnostics and decision making, increasing production uptime with less engineering effort.

Read MoreSwiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

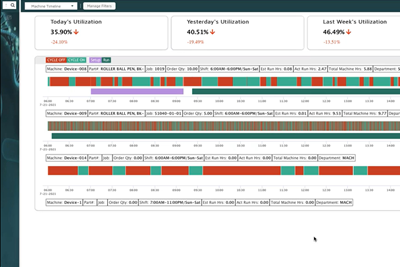

WatchMSC Machine Monitoring Optimizes Manufacturing Processes

Westec 2023: MSC Machine Monitoring provides out-of-the-box connectivity to up to 10 machines and in-depth data on customizable, intuitive dashboards.

Read MoreECI Monitoring System Provides Actionable Insights

Westec 2023: By triggering actions that reduce downtime, scraps and failure, Alora increases utilization of existing machinery and staff.

Read More

.png;maxWidth=300;quality=90)