EDM

Hybrid Control Makes Lights-Out EDM More Accessible

This CNC enables EDMs to switch between G-code and an integrated CAM system to adapt to changing conditions and make lights-out manufacturing more attainable.

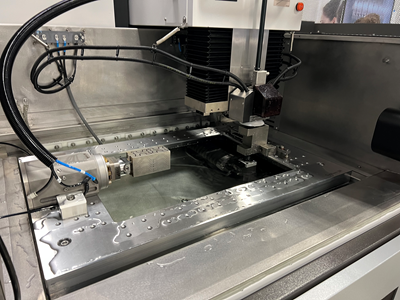

Read MoreEDM Network's Wire EDM Targets 3D-Printed Mold Component Removal

EDM Network introduces the EDMMax 434W that enables customers to economically cut 3D-printed mold inserts from their build plates.

Read MoreMC Machinery EDM Offerings Provide Optimized Performance

MC Machinery’s Mitsubishi SG12 and MV2400 EDMs provide ergonomic and efficient operations.

Read MoreSodick Die-Sinker EDM Fits Range of Automation Needs

The Sodick ALG EDM series doubles motor response speed for the development of accurate, high-quality molds, and is equipped with automated features for continuous operations.

Read MoreEDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreGF Machining Solutions EDM Features Enhanced Control

The Cut F 600’s iWire function automatically identifies and adapts wire speed to changing erosion height conditions during the wire EDM process, eliminating wire breakage while reducing overall wire consumption.

Read MoreWall Colmonoy Acquires New Wire EDM From Sodick

The company will use the new wire EDM machine to increase capacity, improve cycle times, achieve tighter tolerances and improve surface finishes.

Read MoreDielectric Oil Dramatically Reduces EDM Maintenance

Plagued by repeated small fires that interrupted its wire EDM throughput, this cutting tool manufacturer changed its dielectric oil and both eliminated fires and reduced its oil consumption.

Read MoreYCM Sinker EDM Features Large Work Envelope

The Exeron 316 Sinker EDM features heavy-ribbed and welded construction for added strength and stability.

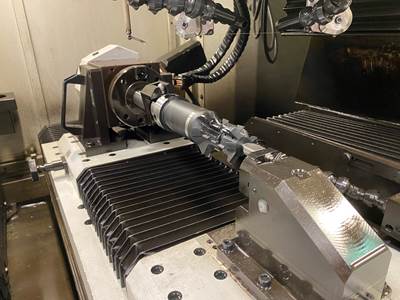

Read MoreEDM Network Introduces Fast Wire EDMs for 3D-Printed Metal Parts

EDM Network's mid-sized, four-axis Fast Wire EDM machine quickly removes 3D-printed metal parts from larger build plates.

Read More