Grinding

Redesigned Grinding Machines Feature Improved Stability

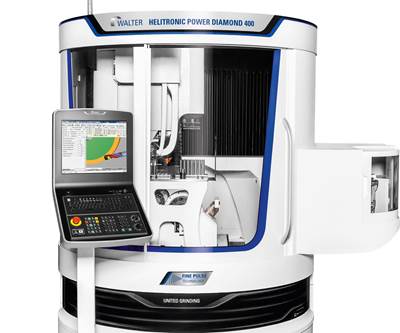

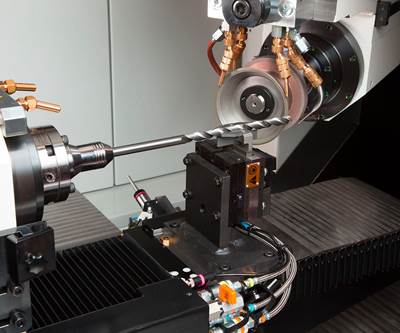

United Grinding Group has redesigned the Walter Helitronic Power 400 grinding machine and Power Diamond 400 grinding and eroding machine.

Read MoreCenterless Sets the Tone for Shop-to-Stage Success

Grinding three shaft diameters at once eliminates runout and helps reintroduce a ‘70s-era guitar effects unit that mimics the action of a violin bow.

Read MoreEvolution of Performance Camshaft Grinding, Finishing

Comp Cams has made numerous improvements to its CNC camshaft grinding process. The company has also implemented what it calls its “Micro Surface Enhancement” finishing technology, which works in tandem with its enhanced grinding process to further improve camshaft longevity and durability.

Read MoreUniversal Cylindrical Grinder Handles Long Workpieces

Studer has introduced the Favorit CNC universal cylindrical grinding machine with a center distance of 1,600 mm (63") to handle long workpieces.

Read MoreRollomatic Group Appoints Strausak Inc. President

Joe Kane has over 14 years of experience in manufacturing and quality assurance.

Read MoreFive-Axis Spark Grinder Sharpens Diamond Cutting Tools

The universal five-axis Dia-2200-Mini from Lach Diamond is designed for the automatic sharpening of diamond tools and saw blades.

Read MoreTool Grinder's CNC Facilitates Unattended Automation

Star Cutter’s NTG 6RL five-axis tool and cutter grinding machine, based on NUM’s Flexium+ CNC platform, automates the high-speed production and reconditioning of complex cutting tools.

Read MoreTool Grinding Center Processes Finish Milling Cutters

Holroyd Precision’s CS700E tool management center is designed to grind high-accuracy profile forms on finish milling cutters as large as 700 mm in diameter.

Read MoreUniversal Cylindrical Grinder Completes Complex Parts in One Setup

Taiyo Koki, a DMG Mori company, announced the U.S. debut of the CVG-series vertical universal cylindrical grinder with pallet changer.

Read MoreCam Grinder Meets Strict Automotive Standards

The Jucam 1S from Junker specializes in the precise, efficient grinding of cam pieces with minimal downtimes to maximize economical production.

Read More

.png;maxWidth=300;quality=90)