Horizontal Machining Centers

Best Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreModular Horizontal Machining Center Offers Uninterrupted Production

According to Starrag, the Bumotec 191neo offers twelve separate machines based on a single platform. The system is designed to address current and future challenges for medical technologies, the luxury industry and the micromechanics sector.

WatchHorizontal Machining Center From Okuma Offers New Features

The new machining center offers a larger work envelope, enhanced chip and coolant management functions and automation compatibility, among other features.

Read MoreStarrag's New Compact HMC Increases Speed, Output

The Heckert H65 provides traverse rates up to 80 m/min and a standard spindle speed of up to 10,000 revs/min from its 60 kW/450 Nm hollow shaft HSK-A100 spindle. A motor spindle with a run-up time of one second can be used for machining light alloys.

Read MoreNiigata Launches HMC With Hardened, Ground Inverted V-Shaped Slideways

According to Niigata, the HN800-V is built with the rigidity and accuracy necessary to perform ultra-precise contour machining and boring of components with critical tolerances.

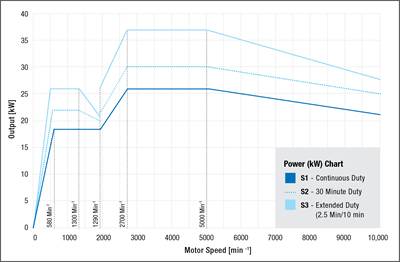

Read MoreBack to the Charts for Productive Milling

Roughing operations can push a CNC spindle to its limits. Understanding how to interpret the horsepower chart can keep these operations within safe limits.

Read MoreStarrag Five-Axis HMC Joins AMRC's Factory of the Future

Starrag Heckert’s X40 joins a series of other multi-axis Starrag-supplied machines at the University of Sheffield Advanced Manufacturing Research Centre’s Factory of the Future.

Read MoreMazak Upgrades Vertical and Horizontal Machining Centers

According to Mazak, both the HCN-6800 NEO and the Variaxis i-800 NEO include a fully redesigned enclosure and improvements that enable fast, optimal solutions for a wide range of part-production applications.

Read MoreNiigata Introduces High-Speed Jig Borer Machining Center

Niigata says the HN800-V is built with the rigidity and accuracy necessary to perform ultra-precise contour machining and boring of components with critical tolerances.

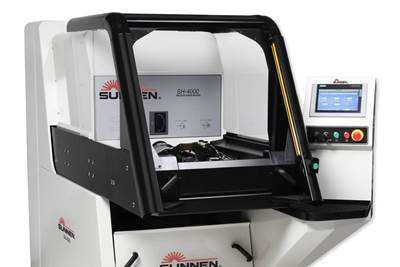

Read MoreSunnen's New Servo-Precise Machining Center

Eastec 2021: Sunnen’s new honing machine is engineered for medium to high production of parts with bore diameters from 1.5 to 102 mm (0.060" to 6.50").

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)