Milling Tools

Emuge-Franken Threading Tools Mill Challenging Materials

The company has expanded its offerings of solid-carbide thread mills with new products for challenging applications.

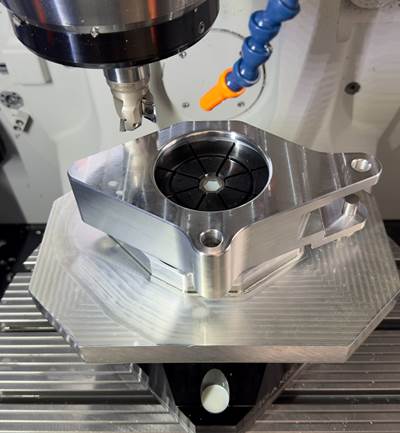

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

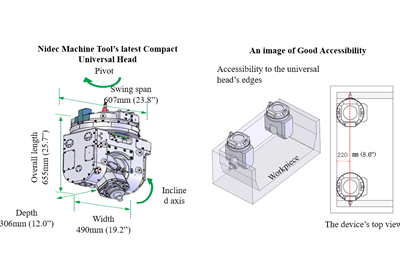

Read MoreNidec Universal Head Enables Versatile Machining

The compact universal head enables better accessibility between the tool and the workpiece, as well as improved surface-finish quality, greater motion range and high-efficiency machining under ideal machining conditions.

Read MoreKyocera SGS Through-Coolant End Mills Improve Chip Evacuation

H-Carb end mills feature a specialized core and flute design improve rigidity and chip flow while reducing deflection.

Read MoreBig Daishowa Milling Cutters Provide Versatile Operation

The company has expanded its lineup of Fullcut Mill FCM tools to include larger diameters and additional lengths.

Read MoreTungaloy Milling Inserts Enhance Cutting Performance

TungAluMill is designed for efficient machining of aluminum alloys and other non-ferrous materials at high speeds.

Read MoreWalter Ceramic Inserts Enable Efficient Turning, Milling

Suitable turning and milling applications of the WIS30 ceramic grade include roughing, semi-finishing and finishing, as well as interrupted cuts.

Read MoreCeratizit Product Update Enhances Cutting Tool Solutions

The company has updated its MaxiMill 273-08 face mill, WPC – Change Drill, as well as the HyPower Rough and HyPower Access 4.5-degree hydraulic chucks.

Read MoreSandvik Coromant Milling Tool Boosts Productivity in Steel Machining

CoroMill MR80 is designed for challenging roughing operations in a wide range of face and profile milling applications in steel and stainless steel.

Read MoreEmuge-Franken End Mill Wins ANCA's Tool of the Year Award

Emuge-Franken received the award for its specialized tool based on the new Cera-Cut end mill design.

Read More

.png;maxWidth=300;quality=90)