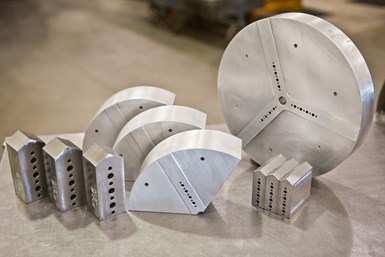

Dillon Pin Location Jaws Hold Sensitive Parts Without Deformation

Each jaw is CNC milled to provide maximum accuracy of workpiece location, enabling air chucks to hold sensitive workpieces firmly.

Dillon Manufacturing Inc.’s pin location jaws are designed to firmly yet safely grip deformation-prone parts. Well suited for thin-walled components, tubing-type products and other sensitive workpieces, Dillon manufactures full grip (pie) blank jaws and soft jaws for Northfield, Microcentric and others. Each is CNC milled to provide maximum accuracy for workpiece location, enabling air chucks to hold sensitive workpieces firmly. Standard sizes are available, as well as custom jaw sizes. Dillon pin location jaws are typically available in three days or less, according to the company.

Full grip jaws are manufactured for chuck sizes ranges between 4" and 10" diameters and are available in 1018 steel and 6061 aluminum. Jaw heights are available between 1" and 4". Soft jaws are available in 1018 steel and 6061 aluminum in heights from 0.75" to 5.00" and widths from 0.75" to 3.00".

Related Content

-

IMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

Moving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.