Workholding

Putting Production on Repeat with Machine Tool Automation

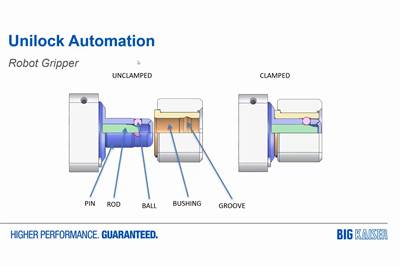

Cobots and automation advances have spurred tooling and workholding innovations like Big Daishowa’s zero-point workholding system and EWA fine boring head.

Read MoreMini Workpiece Positioning System Offers Fast, Flexible Setup

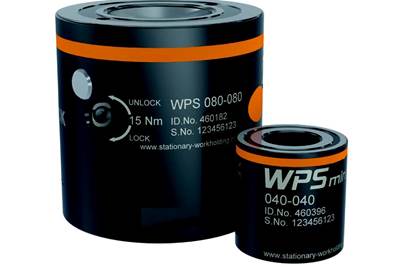

SMW Autoblok’s 40-mm Workpiece Positioning System (WPS) Mini is designed to reduce setup times and offer flexibility, especially for small workpieces that require quick part changeover.

Read MoreWorkholding 101

No universal workholding solution exists, so machine shop employees should have a basic understanding of multiple ways they can secure workpieces.

Read MoreSchunk Upgrades Low Maintenance, Quick-Change Jaw Chuck

Schunk says its Rota THW3 quick-change jaw chuck is particularly beneficial for users who produce small and medium quantities and are frequently switching between jobs.

Read MoreFull-Grip Chuck Jaws Hold Delicate Workpieces Without Marring

Dillon Manufacturing says its full-grip chuck jaws are ideal for high-speed machining, as well as precision boring, tapping, drilling and finishing across virtually all industrial markets. Brass provides a softer surface without marring or marking of the workpiece surface.

WatchKurt Manufacturing Introduces Compact Vise

The 8" DX8 CrossOver vise features a redesigned nut with less weight, a new brush seal design and a larger, stronger bearing pack for more durability.

Read MoreSMW Autoblok Acquires Tecnomagnete

Tecnomagnete is said to have invented the use of permanent magnetic systems for component clamping, plastic injection molding, stamping and lifting.

Read MoreQuick Fixture Changing System for Heavy-Duty Machining

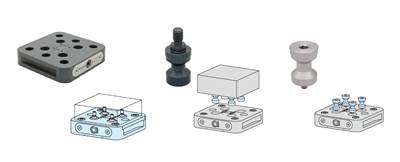

IMAO Fixtureworks' Flex Zero clamping system reduces downtime during fixture changes. It is designed for quick change of pallets, workpieces and vises in five-axis and vertical machining centers, and the strong clamping forces enable heavy-duty machining.

WatchSchunk's Automated Vise Offers Chip-Repellent Design

The Tandem PGS3’s compact design and square shape optimizes accessibility and enables a stroke of 6 mm per jaw. With a clamping force of 4,500 N and a repeat accuracy of 0.02 mm, the vise is said to be suitable for basic applications in aluminum and plastics machining.

Read MoreSchunk's New Chuck Jaw Clamps a Range of Geometries

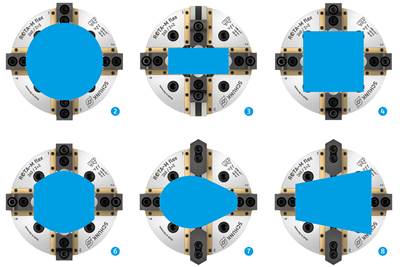

Schunk’s Rota-M Flex 2+2 chuck jaw is designed to provide increased flexibility for clampable workpiece geometries and a variety of possible applications.

Watch

– Medium Rectangle (1).png;maxWidth=300;quality=90)