Because the ability to make deep holes effectively and efficiently is critical in many applications, deep hole technology is one of the most highly developed sectors in metalworking. It covers a diverse range of processes and methodologies. Unisig (Menomonee Falls, Wisconsin), a supplier of machines, tools and automation for deep hole making, says the list of industries it serves includes aerospace, automotive, defense, hydraulics, mold making, oilfield and energy. Yet deep hole making is largely the domain of shops specializing in this capability, whereas technology suppliers such as Unisig believe that a wider awareness of deep hole making processes would alert new users to valuable opportunities.

As an example of how deep hole technology has mastered some of its most extreme challenges, Unisig points to one particularly interesting technique: pull boring, which enables users to achieve remarkable straightness in deep holes. A variation of this technique is also effective when maintaining consistent wall thickness (in long, cast pipes, for example) is top priority.

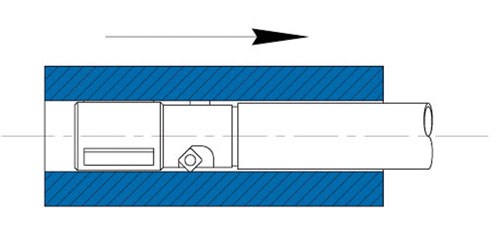

As its name implies, pull boring involves pulling a cutter through an existing hole. Pull boring is usually performed on the same machine that created the original hole. In this case, a boring bar is inserted all the way through the existing hole. After emerging at the opposite end, the bar is fitted with a single-point pull boring head. The bar is then engaged in the tool drive mechanism and drawn back through the workpiece. The bar rotates in one direction, while the workpiece is rotated in the opposite direction by the work spindle. The tooling head holds a carbide insert of the appropriate grade and style for the workpiece material. This insert functions much like an ID turning tool, enlarging the original hole slightly as it is pulled into the workpiece. Coolant pumped around the boring bar channels chips up and out through its hollow center to aid metal removal and protect the surface.

According to Sarang Garud, a Unisig applications engineer, hole drift tolerances achieved by pull boring can be less than 0.001 inch per foot (0.08 mm/meter) of workpiece length, if material, tooling and process conditions are favorable. However, reaching this level of straightness may require several passes.

For concentricity, a multi-point pull-boring head is used instead of a single-point tool. A multi-point tool typically has between two and six inserts, Mr. Garud says. Wear pads are located in front of the inserts so that the existing ID of the bore provides support during cutting. In contrast, a single-point head is supported by the finished bore ID, so wear pads are located behind the insert.

Mr. Garud notes that pull boring involves several nuances. For example, it is customary to make the original hole by boring halfway through the part, turning it end for end and boring the second half of the hole. This practice reduces the overall out-of-straightness condition in the resulting hole because each half of the bore will show less drift compared to a hole bored all the way through in a single pass. Thus, pull boring has a “head start” in its straightening action.

Pull boring can be applied to any part that a deep hole machine can accommodate. The only limit on part length is the length of the deep hole machine. Likewise, pull boring benefits from the same qualities of accuracy and rigidity in the deep hole machine that affect the original boring operation. In addition, sensing the rate and pressure of coolant flow, which the Unisig machines do automatically, enables users to protect workpieces and cutting tools by closely monitoring cutting conditions during pull boring.

A special accessory that makes pull boring more efficient is the lantern chuck. A drum-shaped device with openings on opposite sides, the lantern chuck is installed at the workpiece headstock end of the machine. The side openings make it easy to install and align a guide bushing for the pull boring tool. The lantern chuck also eliminates the need to machine a special pilot hole otherwise required so that the pull boring tool enters the workpiece on center.

Advances in deep hole technology will strenghten the capability of specialist shops while widening its use in general metalworking. By providing complete machining systems, tooling, coolant, accessories and process know-how, Unisig says it is ready to support customers following either trend.