Many mold makers face the question of whether five-axis machining makes sense for the kinds of complex workpieces these shops routinely produce. For Chicago Mold Engineering (CME) in St. Charles, Illinois, the answer to this question is already clear. The answer is yes—five-axis machining is the way this mold supplier is committed to making its highest-value parts. Lately, this shop has turned to the question that comes next. Namely: Which type of five-axis machine is better? The answer to this question depends on the part, the shop says. As CME’s five-axis capabilities have expanded, the company has seen how different applications favor tilting-spindle or tilting-table five-axis machine tool designs.

Much of the five-axis machining at CME is actually five-side or 3+2 machining. In this type of machining, the rotary axes pivot only between passes, remaining fixed during the cut. While CME frequently does produce five-axis-milled surfaces by feeding with the rotary axes, the argument for five-axis machining remains strong whether or not these axes are used for milling directly. By using the axes just to reorient the angle of cutting, the shop can reach hard-to-access features of the part without a tool extension and can machine various side features of the part in a single setup. This reorientation can even let the shop mill a flat surface at the most favorable angle between workpiece and tool. All these advantages translate to time savings. That’s why, for machining cores and cavities, CME President Jeff Oswald says, “I don’t think we’d buy another machining center that wasn’t five-axis.”

Tilting Spindle Versus Trunnion

The company began five-axis machining with a Fidia machining center that uses rotary axes to pivot the spindle head. Subsequent five-axis machines have come from Fidia as well, and for a time, all the machines the shop chose featured this same kind of tilting-spindle motion. The company’s specialty is automotive headlight molds, for which cores and cavities are relatively large. For these big parts, the best application of five-axis is to let the parts sit still on the table while the spindle moves and pivots all around them.

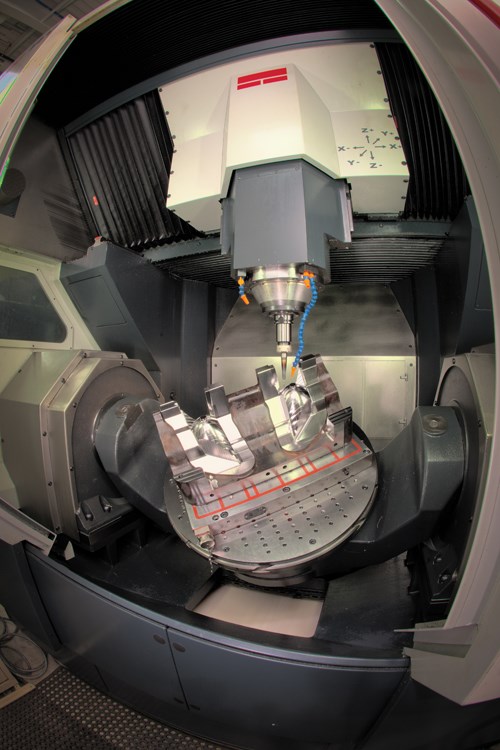

Yet CME does mold work for other industries, too, and a recent, smaller mold suggested a different type of five-axis machine. The molded part was a disk with ribs around the periphery. The corresponding tool included slots in the inner ring for forming these ribs. The slots called for continuous five-axis milling, but the titling-head machine would have required various setups to access every slot from both above and below this small part. In contrast, a trunnion-type machine—one that tilts the workpiece rather than the spindle—would make setup much simpler. Such a machine would also be able to index the part to mill every slot in one cycle.

The shop had not considered itself a candidate for this type of five-axis machine before. On a trunnion-type machine, the part is restricted by clearance limitations. Specifically, the part’s length and width both have to fit within the rotary table’s circle of motion, and CME’s cores and cavities are typically too big for this. This new job was smaller in scale. Given that more of this type of work seemed likely, management debated buying a five-axis machine better suited to the job. CNC foreman Bill Kloskowski went to

Fidia’s facility in Troy, Michigan to experiment with a trunnion-type model. His experience strengthened his opinion of it, and he reported as much back home. CME’s internal debate ended with the purchase of a Fidia G996 trunnion-type five-axis machining center in early 2011. Before the year was over, the shop had already bought and installed its second of these machines.

What the shop discovered is that much more of its work belongs on a trunnion-type machine than it had previously assumed. Part of why Mr. Kloskowski was pleasantly surprised is because the machine proved to have a larger practical working envelope than he and others in the shop had imagined. Machining with a tilting spindle head had made CME accustomed to allowing room for this head at every angled cut. For example, a right-angle side cut might require the spindle ram to be offset from the part by 10 inches to leave room for the head and its tilt. An undercut might require the part to be set on risers to leave room for the spindle to locate underneath. But on a trunnion-type machine, the spindle is fixed. Rotating the table gives this spindle equal access to any surface around the part. And while the machine cannot hold a large core or cavity, it can hold mold inserts. At CME, at least 80 percent of the molds use inserts that can now be milled efficiently on this style of machine.

Slide Rule

For some parts, the trunnion-style machine offers even better access than the tilting-spindle alternative. Mold slides are an example. The long parts could be set up in pairs on a tilting-spindle machine’s table, but the clearance needed for the spindle head impeded this head from reaching all the way around these two parts together. By contrast, a trunnion-style machine can easily machine the two slides in one cycle. In this machining, only two faces of each part are hidden from the spindle—the face touching the table and the face adjacent to the other slide. By reaching all of the other faces of the slide parts, this one cycle can machine the two parts nearly complete. Slides are now candidates for five-axis machining where they generally were not in the past. This is more than five-side machining, the shop says. Given the four sides per part that can be machined, it’s actually eight-side machining.

In fact, the leadtime savings are even greater than what this combined cycle would suggest. Because the slides no longer require three or more setups, they don’t need square surfaces to serve as references through various operations. A dowel can serve as reference for the part’s machining instead, including the machining that will square the surfaces. As a result, Mr. Kloskowski now often finds himself insisting to shop personnel that they do not pre-square slides—contrary to habit. That work is a waste of time if five-axis machining can make it unnecessary.

Size Factor

Of course, trunnion-type machines are not automatically the more effective choice. Tilting-spindle machines remain just as valuable to CME as they ever were—not only for cores and cavities, but also for deep recesses. There is a right five-axis machine type for each part. It’s just that the choice between the two styles is more balanced than the shop would have expected before it became experienced with a trunnion-type machine.

One final advantage of the trunnion-type relates to roughing. The fixed spindle is rigid enough to permit rough milling, while the tilting-spindle machines generally only finish. Mr. Kloskowski says he routinely mills mold steel with a 2-inch-diameter cutter on a trunnion-type machine, something he would not do with the other five-axis equipment. This ability to rough and finish in one setup produces even more streamlined machining of molds. In fact, lately it has streamlined the machining of other part types as well.

In late 2011, just as its second trunnion-style machine was arriving, CME started work on a five-axis job outside of mold making—a run of Inconel parts for the power-generation industry. Mr. Oswald says the shop expects to see more of this work in the future. In quoting on this job and winning it, CME discovered that its five-axis capabilities now stand out not only among mold shops, but also among shops performing five-axis machining for production.

New Online Video: Five-Axis Machining at Chicago Mold Engineering

“It’s not always obvious which job to cut on which machine,” says CME’s Bill Kloskowski in a new video on five-axis machining that can be seen on MMS Online. The video shows CME’s five-axis machines in action, with both tilting-spindle and tilting-table machines milling parts and moving through their full ranges of motion. Plus, CME personnel have even more to say about the advantages of five-axis machining, including the leadtime savings, the reduced need for EDM and the ability to cut with shorter tools. As Jeff Oswald says in the film, “Five-axis machining is very important to Chicago Mold”—this video illustrates why. To view it, click here.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=600)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)