#MFGDay15 Illuminates and Bridges the Manufacturing Divide

Gaps in workforce skills and public perception are nothing new to manufacturing. What is Manufacturing Day doing to help, and what happens after outreach?

Share

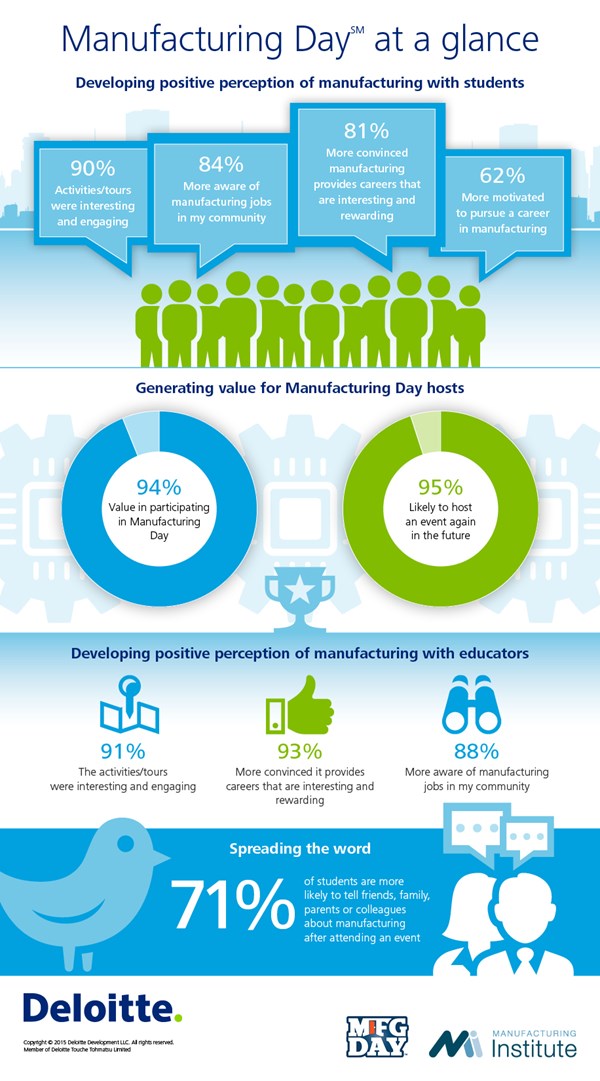

Photo courtesy of The Manufacturing Institute.

It’s no news that U.S. manufacturing faces a challenge: growing the workforce. There are increasing calls to reach out to the community and to schools, to make manufacturing relevant to millennials, to change perceptions of what some people see as a dingy, dangerous or old-hat field of work.

To try to change perceptions and facilitate just this sort of outreach, Manufacturing Day (MFG Day)—coordinated by The Manufacturing Institute—presided over more than 2,600 events held across the United States, Canada, Mexico and Puerto Rico in 2015, reaching more than 400,000 participants. Unified on social media by the hashtag #MFGDay15, these events were hosted by manufacturers who opened their doors to students and community members to showcase modern manufacturing.

Based on a Deloitte survey of participating teachers, students, parents and employers taken after MFG Day 2015, the effort seems to be working.

Find the infographic and more detailed survey results at mfgday.com.

According to The Manufacturing Institute, the survey found that after attending MFG Day events, 81 percent of student respondents were more convinced manufacturing provides careers that are both interesting and rewarding, and 71 percent were more likely to tell friends, family, parents or colleagues about manufacturing.

Ninety-four percent of manufacturers surveyed found value in participating in the event and 88 percent are more likely to continue engaging with high schools or colleges in their area.

Illuminating the Divide

The avowed purposes of MFG Day speak to the gaps in labor skills, demographics and perception that trouble manufacturers. An earlier Deloitte study found that while 90 percent of Americans believe manufacturing is very important to national prosperity, only a third of parents on average would encourage their children to pursue a career in it.

That said, the study also found that those familiar with manufacturing were twice as likely to encourage a child to pursue a manufacturing career.

In that light, the event’s focus on getting manufacturers to engage with local communities and expose young people, their teachers and parents to modern manufacturing would seem to be the ticket to improving the odds for manufacturing’s future.

Bridging the Divide

The divide between potential machinists and established professionals often manifests as differences in age, demographics and culture. Some manufacturers may find bridging those gaps difficult. The MFG Day approach helps make it easier for event hosts to connect with the community—particularly the younger crowd—where they are. That means local venues. It also means social media.

To this end, MFG Day and its partners have put effort into providing a variety of toolkits and guides for reaching out to and capitalizing on local and trade media, social media, schools, and others. Edge Factor got involved as well as Science Channel, publishing material that local hosts and organizers could use and distribute to put manufacturing on kids’ radars.

But even if students and their parents change their perceptions of manufacturing, what’s supposed to happen then?

What Happens After Outreach

As Editor Pete Zelinski wrote recently, “One thing these outreach efforts often lack is a specific way forward. If a young person becomes interested in machining…then what should he or she prepare to do to follow this interest and proceed into this career?” In that blog, Mr. Zelinski cites a document by a professional machinist who describes his own career path and recommends concrete steps in pursuing a manufacturing career.

For other material on this topic, you may want to check out Russ Willcutt’s MMS Online blog post on drawing millennials to manufacturing or maybe the 13-part series on finding, training and retaining employees Ryan Pohl contributed to MoldMaking Technology.

To begin planning for your own MFG Day event in 2016, go to mfgday.com and access the site’s event planning resources. While you’re there, you may want to peruse Facebook, Instagram or Twitter to see what other event hosts did on these platforms in 2015.

Related Content

Preserve the Craft of Manufacturing as Technology Advances

As the industry continues to move toward a digital future, be sure to reinforce the core fundamentals right alongside it.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreHow I Made It: Craig Cegielski

Craig Cegielski tells us about the founding and successes of student-run manufacturing business Cardinal Manufacturing and offers advice for setting up a student-run manufacturing business in your own school district.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More