KYOCERA SGS Precision Tools

World Headquarters

150 Marc Drive

Cuyahoga Falls, OH 44223 US

330-688-6667

webmaster@kyocera-sgstool.com

kyocera-sgstool.com

About KYOCERA SGS Precision Tools

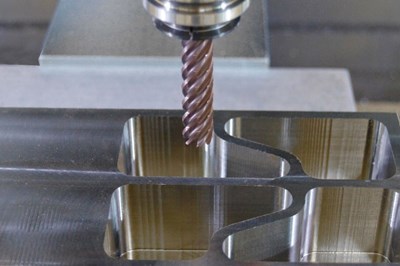

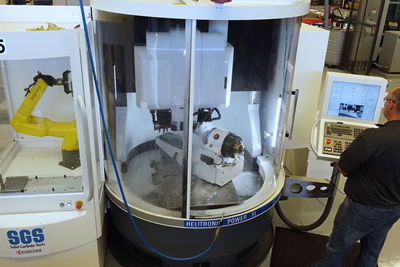

An ISO-certified supplier of round solid-carbide cutting tool technology for high-performance industries, such as aerospace, medical and power generation. Has a global network of sales representatives, industrial distributors, and agents that blanket the world.

IS THIS YOUR COMPANY?

As Seen On Modern Machine Shop

KYOCERA SGS Precision Tools Supplies the Following Products

Trade Names Offered by KYOCERA SGS Precision Tools

- Di-NAMITE

- Hi-PerCarb

- Ski-Carb

- Ti-NAMITE-A

- Z-Carb-HTA

- Z-Carb AP

- Series 33

- Multi-Carb

- Z-Carb-MD

- Turbo-Carb

- Z-Carb

- Ti-NAMITE

- V-Carb

- S-Carb

- ICe-Carb

- Ti-NAMITE X