Top Shops Profile: XL Machine

XL Machine Co. Inc. was 2017's Top Shops Honors Program winner in the category of machining technology.

Share

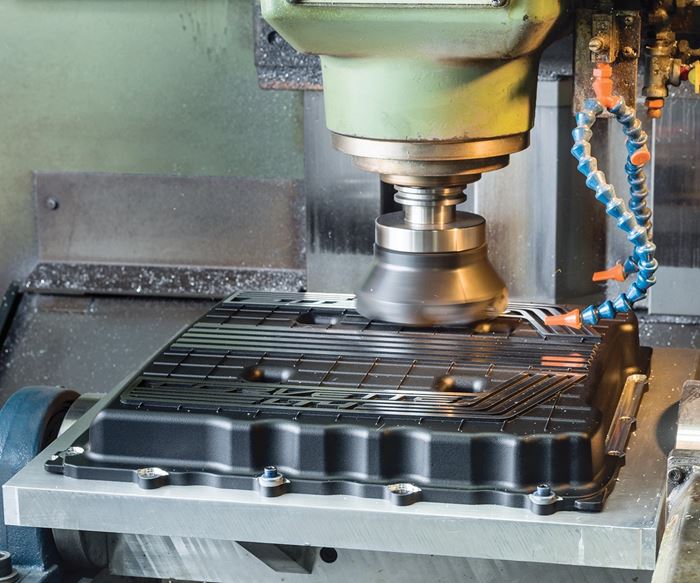

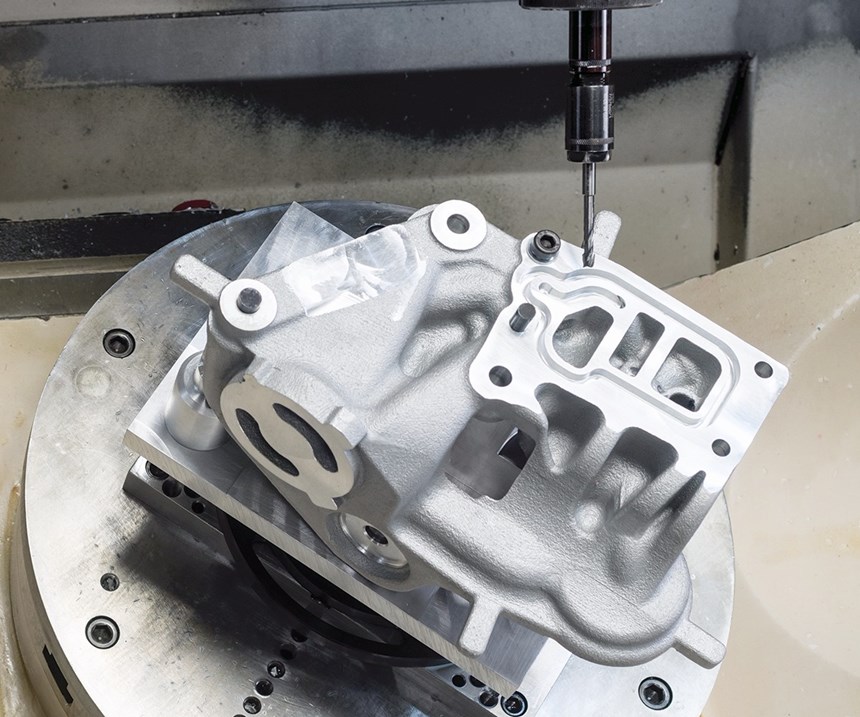

XL Machine is this year’s Top Shops Honors Program winner in the machining technology category. The shop has more than 75 CNC machine tools in its Three Rivers, Michigan, facility that are well-suited for prototypes, tooling, low to medium volume production runs and specialty production runs. This includes advanced equipment such as HMCs, five-axis machines, turn/mills and a universal grinding machine. Many of these are fitted with features such as touch probes, tool setting probes, quick-change fixturing, magnetic chucks, high-pressure through-tool coolant delivery and collision avoidance systems.

Founded in 1976, XL Machine began as a quality, prototype machine shop. Today, this core function is paired with a more complete, large-capacity production facility. The shop believes its ability to invest in new technology continues to provide the leading-edge capabilities necessary to distinguish itself from its competitors.

End Markets Served

- Automotive

- Die/mold

- Equipment/machinery

- Off-road/construction

- Power generation

Workpiece Materials Commonly Machined

- Aluminum

- Brass

- Bronze

- CFRP

- High-temp alloys

- Stainless steel

- Steel alloys

- Titanium

- Tool steel

Related Content

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

-

Building a Better Business: Lessons for Machine Shops From an Unexpected Source

Learning how to be a great manufacturer by listening to the insights of a different industry, homebuilding (which perhaps is not so different after all).

-

Benchmarking: An Invaluable Business Tool

Modern Machine Shop’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

Related Content

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreBuilding a Better Business: Lessons for Machine Shops From an Unexpected Source

Learning how to be a great manufacturer by listening to the insights of a different industry, homebuilding (which perhaps is not so different after all).

Read MoreBenchmarking: An Invaluable Business Tool

Modern Machine Shop’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreRead Next

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)