Press and representatives from all over the world gathered at Studer AG’s headquarters in Steffisburg, Switzerland, for the company’s annual meeting, which included a press conference and a guided facility tour.

Fritz Studer AG, a member of the United Grinding Group, held its annual meeting on Feb. 9, 2024, at its headquarters in Steffisburg, Switzerland. This year’s event was titled the “Music Motion Meeting” with the theme of “Sound of Studer.” Approximately 65 journalists from over 20 countries attended the event, which began with presentations from the company’s board of directors. After the conference, attendees were given a guided tour of Studer’s headquarters, which featured demonstrations and explanations of entry-level grinding machines and automation solutions.

Market Outlook

The press conference featured a rundown of 2023 sales figures. CEO Jens Bleher says the year was “extremely successful,” with sales growth in two of its largest markets: the U.S. and China. Asia was, as it has been in previous years, the largest region for sales alongside Central Europe and North America.

Although the development of incoming orders was weaker in individual markets, such as Germany, China, and some Asian countries, other parts of the world saw positive results. “We achieved good results in many countries and even posted a new record order intake in some,” says Studer CSO Sandro Bottazzo. The customer care segment of the business set a sales record for the second consecutive year. Customer care includes areas from maintenance and service to spare parts and overhauls.

Measured by customer segments, the aerospace industry once again generated the largest increase in new orders. The industry has now overtaken the declining automotive and supplier industry. The tool segment remained below expectations, while the largest individual segment is precision engineering, which is dominated by contract manufacturers. “I am very pleased that our grinding machines are so highly trusted by small and medium-sized enterprises, and that this segment remains strategically important for us,” says Bottazzo. Additionally, Studer is seeing an increasing demand for precision cylindrical grinding machines in the semiconductor industry.

Automation and Entry-Level Solutions

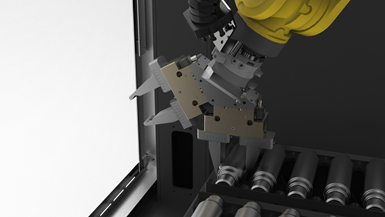

The InsertLoad automation solution supports the loading and unloading of S33 and S31 universal cylindrical grinding machines — and can load workpieces between centers and into the chuck. Source: Studer AG

Globally, Studer participated in about 30 trade shows and open houses. At EMO 2023, the company unveiled its new InsertLoad loading system, which it also showed during the facility tour. The new universal loading system enables standardized automation for loading and unloading Studer’s S33 and S31 grinding machines. InsertLoad can be used for center distances of up to 39.4 inches. The workpieces can be up to 3.94 inches long and weigh 3.3 lbs in alternating mode or 11 lbs in a single mode. The design and ease of use with the digital setup wizard allow users to configure this for centers and chucks – no programming knowledge is required. Additionally, InsertLoad can handle workpieces that are stored either vertically or horizontally. Loading and unloading is handled by a FANUC robot, which moves independently on a linear axis between the loader and the machine’s work area. This system can reduce the time without human operator intervention, which typically is between thirty and sixty minutes.

Studer says the Favorit — part of its entry-level line of machines — can grind both short and long workpieces weighing up to 330 lbs. Source: Studer AG

The machines in the entry-level segment include the Favorit, FavoritCNC, and S100. The Favorit is a cylindrical grinding machine with a 24-inch touch screen, and the company says it can grind both short and long workpieces that weigh up to 330 lbs. The FavoritCNC can be adapted to a variety of grinding tasks with different options such as a measuring system, balancing system, contact detection, and longitudinal positioning. With a distance between centers of 25.6 inches or 39.4 inches, it is suitable for a variety of uses.

Studer says its FavoritCNC can be adapted to a variety of grinding tasks with different options such as a measuring system, balancing system, contact detection, and longitudinal positioning. Source: Studer AG

The S100 handles a wide range of internal, face, and external grinding applications. Its specialty is the complete machining of workpieces with a length of up to 21.65 inches (including clamping devices) and a diameter of up to 16.5 inches. Thanks to the wheelhead with multiple grinding spindles, Studer says these features significantly reduce setup and resetting costs.

“We are continuously expanding our entry-level range for customers who appreciate Studer quality and utmost precision but do not need all the features from the premium segment,” Bottazzo says.

Studer says the S100 is easy and quick to control, with ergonomically arranged operating elements. Source: Studer AG

Adds Daniel Huber, CTO of Studer, “Compared to our high-end models, the number of tools and range of spindle power is limited, and many technical processes and interfaces standardized — this allows (the entry-level machines) to cover a wide range of grinding applications with excellent value for money.”

Fritz Studer Award

Studer concluded the conference portion of its event by presenting the 2023 Fritz Studer Award. Dr. Emil Sauter from the Institute of Manufacturing Technology and Machine Tools at ETH Zurich was the award winner, receiving a prize of 10,000 Swiss francs, or just under $11,400. His topic, “Detection and avoidance of thermal damage for high-performance metal grinding processes using hybrid machine learning models,” deals with the development of an innovative condition monitoring system for external cylindrical grinding with metal-bonded CBN tools that recognizes thermal damage and predicts the remaining useful life of grinding tools with relative accuracy. Process parameters such as structure-borne noise, spindle current, force characteristics and the use of time-frequency transformations generate features of a grinding process to detect different stages of thermal damage to the workpiece.

Dr. Emil Sauter, left, is presented the Fritz Studer Award by Studer CTO Daniel Huber.

The award is aimed at graduates from European universities and technical colleges. Research focus for the award covers any of the following topics:

-

Innovative machine concepts or components for machine tools used in precision machining

-

Alternative materials in the machine tool industry

-

Simulation models for the dynamic and thermal behavior of machine tools

-

Control and sensor concepts for machine tools

-

New or evolved manufacturing techniques, especially in precision finishing processes like grinding, hard turning, etc.

“The objectives of the research prize are, on the one hand, to boost innovation in the machine tool industry with feasible solutions, and on the other hand, to promote young technical and scientific talents,” says Dr. Frank Fiebelkorn, head of research and technology at Studer.

This year’s event concluded in the evening with a group dinner in Bern, which featured live music and entertainment.

Related Content

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreNiche Work If You Can Get It: A CNC Machine Shop Crafts Its Own Destiny

The latest innovations in metalworking aren’t always related to CNC automation or robotics. For Rosenberger North America, a 2022 Top Shops Honoree, it is the company’s niche processes that create the biggest successes.

Read MorePartial Automation Inspires Full Cobot Overhaul

Targeting two-to-four hours of nightly automation enables high-mix manufacturer Wagner Machine to radically boost its productivity past a single shift.

Read MoreModern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)