Measurement

Acu-Rite Offers Software Upgrade for Digital Readouts

Heidenhain’s Acu-Rite brand offers a free software upgrade for its 100, 200 and 300 models of digital readouts (DROs).

Read MoreAIMS Metrology Shifts Production to Aid Health Providers

In response to the coronavirus pandemic, AIMS is shifting its machining and metrology capabilities to the manufacture of medical parts.

Read MoreTraceability Without Serial Numbers: Vision Technology Makes Every Part Its Own Identifier

Off-the-shelf imaging technology is now so good it can pick up the distinct surface features of seemingly identical parts. This startup company’s technology leverages what cell phones and other imaging devices can now do, identifying parts by their own unique features so that no serial number is needed.

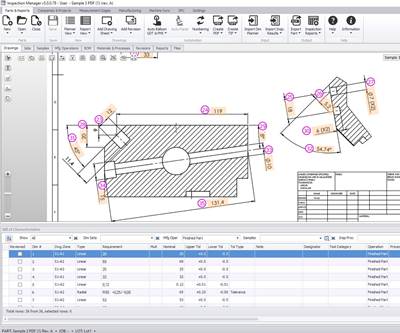

Read MoreHigh QA's Inspection Manager 5.0 Improves Support for ISO, BSI, ASME Standards

High QA’s Inspection Manager (IM) 5.0 includes features for higher quality standards and increased automation.

Read MoreNUM Adds Form Compensation Option to Numroto, Eliminating Need for Third-Party Software

A new form compensation option for NUM’s Numroto tool grinding software enables tool manufacturers to close the loop between CNC tool grinding and measurement.

Read MoreCoordinate Metrology Society Conference Opens Registration

The 36th annual Coordinate Metrology Society Conference (CMSC) is scheduled to be held July 20-24, in New Orleans.

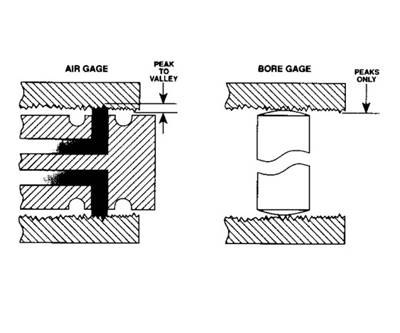

Read MoreWhat’s the Correct Reading?

A CMM, a bore mic and an air gage measure parts differently and may provide different values, yet all of them may be correct. Here’s how.

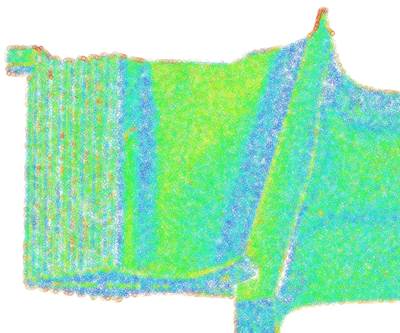

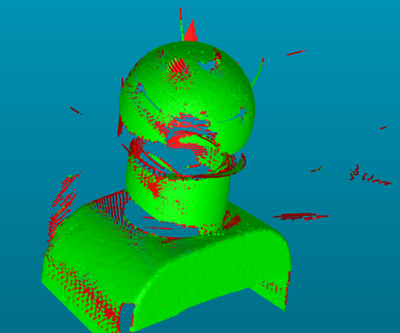

Read MoreHexagon's PC-DMIS 2020 R1 Eases Use of Portable Measuring Arms

PC-DMIS 2020 R1 offers features, capabilities and an enhanced user experience to portable measuring arm operators and those who scan and create point cloud data.

Read MoreNew CMMs Gather More Data, Faster, for Automotive QC Department

Continental’s single-touch-probe CMM was bogging down quality control and limiting the information the company could glean for safety inspections. Two Altera CMMs from LK Metrology cut cycle times and increased insight.

Read MoreExact Metrology Opening New Facility in Illinois

A product of increasing demand in the region, the Moline, Illinois, facility will serve Illinois and Iowa.

Read More

.png;maxWidth=300;quality=90)