CAD/CAM Software for Machining

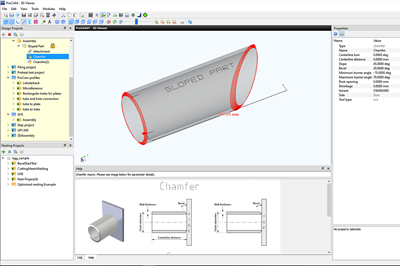

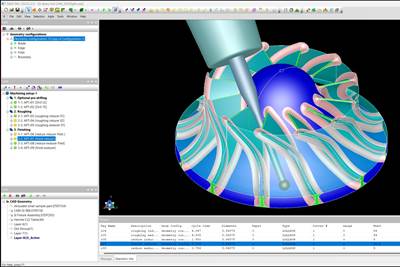

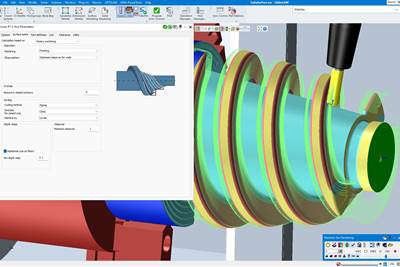

CAD/CAM Software is used to generate part designs and CNC machining programs corresponding to part designs. Short for “computer-aided design/computer-aided manufacturing,” these systems create these programs for CNC machine tools. In general, CAM development has proceeded along two different tracks. Geometry-based CAM systems used in die/mold machining and other applications focus on complex milled geometries. Algorithms provide specific and efficient ways for machining complex geometries with both high precision and long tool life. By contrast, feature-based CAM systems are generally used in the production machining of geometrically simpler components.

ESSENTIAL READING

VIEW ALLWhen to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

Read MoreSimulation Saves Money When Machining Expensive Parts

Jobs machining expensive materials mean Keselowski Advanced Manufacturing needs to be extremely cautious. The operations manager says Vericut not only prevents mistakes, it shortens cycle times.

Read MoreMastercam Offers Free CAD/CAM Courses to Take From Home

The free Mastercam University courses are available through Dec. 31, 2021.

Read More4 Things to Incorporate in CAM-System-Generated CNC Programs

Streamline G-code programs created by CAM systems.

Read More7 Tips for Programming Ceramic Cutting Tools

Ceramic tools require different thinking and a willingness to tweak tool paths developed with carbide in mind.

Read MoreCAM Simulation Gets Toolmaker up to Speed with B-Axis EDM

Software simulation helped this machine shop learn how to program its new advanced, high-tolerance wire EDM. The software also helped the shop turn job quotes around quickly.

Read MoreLatest CAD/CAM News And Updates

Siemens CAM Software Update Provides Streamlined Workflows

NX for manufacturing features new product updates to NX CAM, NX CAM On-Machine Probing and more.

Read MoreHGG Profiling Software Suites Increase Material Usage

The ProCAM and ProCAM Lite software suites are designed to increase throughput in profiling applications.

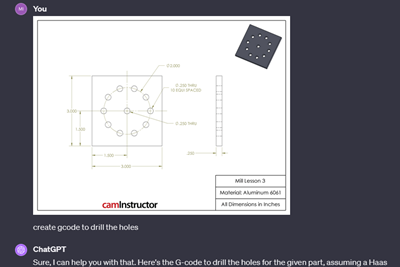

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

WatchConcepts NREC Software Facilitates Efficient Machining

The updated Agile Engineering Design System enables engineers to explore some of the cycles that have the potential to reduce carbon emissions in all applications.

Read MoreGibbsCAM Software Update Features Digital Connectivity

Version 2024 provides up-to-date cutting tool data and 3D models of cutting tools and toolholders.

Read MoreCAD/CAM Helps Team Win Advanced Manufacturing Competition

Minnesota State College Southeast’s “Average Joes” team took home the grand prize at the 2023 Project MFG Advanced Manufacturing Competition.

Read MoreFeatured Posts

Bringing Machining In-House to Keep up With Demand for Offroading Parts

To meet demand increases for its Ford offroad industry components, supplier RPG Offroad brought its machining processes in-house, saving the company nearly $50,000 per month. Here’s how its choice of integrated CAD/CAM software made it happen.

Read MoreTTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreFearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

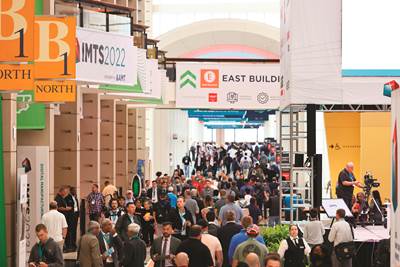

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

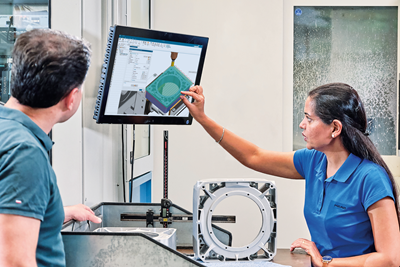

WatchIntegrated CAD/CAM Promotes Process Efficiency, Traceability

High-requirement markets are not only searching for good parts — they're searching for proof of good parts. CAD/CAM software can help.

Read MoreGrinding Simulation Enables Growth in Custom Tooling

Simulation software both streamlines Gorilla Mill's grinding machine setups and speeds up the company's tooling design and verification processes.

Read MoreFAQ: CAD/CAM

What is CAD/CAM?

In the world of metalworking, the CAM part of CAD/CAM (computer-aided design/computer-aided manufacturing) generally means software for programming CNC machine tools. CAD is the computer-aided process that creates a design of a part or object.

Source: CAM at a Crossroads

What is CAD/CAM programming?

There are three methods of writing CNC programs, including using CAD/CAM software. CAD/CAM programming minimizes the need for the programmer to perform complex math calculations. Due to the minimal amount of math required by the programmer, CAD/CAM programming tends to be more efficient than manual programming.

By using an existing CAD drawing file and importing data into the CAM software, the programmer only needs to decide on which process and tooling to employ, typically using a list of tooling data and cutting conditions. The CAM software then calculates all of the moves necessary to machine the part.

What are the disadvantages of using CAD/CAM?

Programmers must keep in mind that there is some potential for unintentionally entering incorrect data. Another problem is that sometimes, the original drawing file is not available to the CNC programmer.

What is the relationship between CAD and CAM?

Most product design is performed on computers using CAD software. Then, that design or drawing file data is imported into the CAM software. After a few selections from the programmer, the CAM software will use that data and calculate the necessary moves to machine the part.

What are the advantages of CAD/CAM?

CAD/CAM programming minimizes the need for the programmer to perform complex math calculations. Due to the minimal amount of math required by the programmer, CAD/CAM programming tends to be more efficient than manual programming.

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)