Deburring

Deburring is perhaps the most critical post-machining operation for ensuring the functionality of the machined part, as well as the safe handling of the part. Deburring has traditionally been a task that takes place after machining to remove any remaining sharp pieces of metal necessary to achieve the desired finish. Deburring has traditionally been a manual task, but various technologies exist for reliably automating deburring.

ESSENTIAL READING

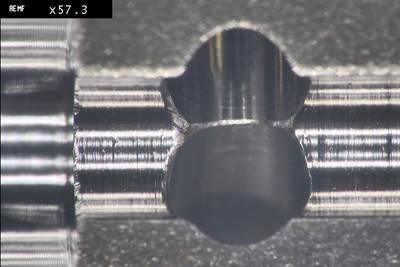

VIEW ALLCross-hole Deburring Tool Eliminates Secondary Process

The Orbitool from J.W. Done helped Paramount Machine eliminate a secondary deburring process, saving 75 process hours across a 2000-part run and enabling the shop to meet its profit and delivery time goals.

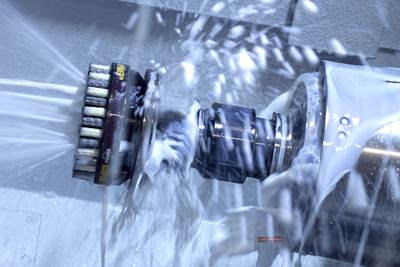

Read MoreThe Case for Abrasive Finishing Tools in CNC Applications

According to Brush Research Manufacturing, abrasive finishing tools do not release large amounts of grit into a machine’s coolant. Hear from three shops using these tools.

Read MoreWhen Sophisticated CNC Machine Tools Aren't the Best Answer

As a machine shop owner, challenges come every day. Sometimes, relying on the tools you’re used to can keep you from finding more beneficial solutions.

Read MoreHigh-Energy Barrel Finishers Efficiently Deburr Complex Parts

Mass Finishing Inc. has developed high-energy barrel finishers that automate the process of deburring complex parts, saving time and eliminating the need to deburr parts by hand.

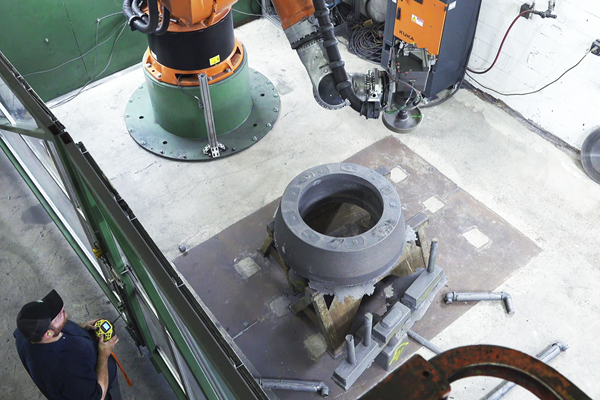

Read MoreShop Hands Over Gear Deburring to a Robot

Manual deburring of gears was an odious task for many of Katsa’s machinists, which in turn created a bottleneck that caused delays. The solution: a custom robotic deburring cell from Flexmill relying on Renishaw’s RMP60 probe.

Read MoreAutomated Part Deburring, Cleaning in One System

Palletized parts are transferred from a five-axis, high-pressure waterjet station to a cleaning station via linear motor to enable fast, automated finishing.

Read MoreLatest Deburring News And Updates

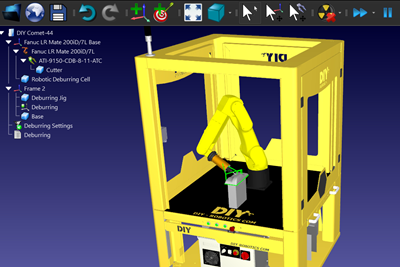

Robotics Partners Design Easy-to-Use Robotic Deburring Cell

RoboDK, DIY-Robotics and ATI Industrial Automation have released a plug-and-play Robotic Deburring Cell technology bundle, which they say rapidly integrates into user systems.

Read MoreRoyal Products Hires New Regional Business Manager

Royal Products has hired Kendal Glotzbach as its new regional business manager for Indiana and Michigan.

Read MoreThe Case for Abrasive Finishing Tools in CNC Applications

According to Brush Research Manufacturing, abrasive finishing tools do not release large amounts of grit into a machine’s coolant. Hear from three shops using these tools.

Read MoreWhen Sophisticated CNC Machine Tools Aren't the Best Answer

As a machine shop owner, challenges come every day. Sometimes, relying on the tools you’re used to can keep you from finding more beneficial solutions.

Read MoreBel Air's AutoHone Uses Robot Arm to Insert, Remove, Clean and Dry Parts

Bel Air’s AutoHone reverse drag finisher rotates the media instead of the parts, which are then dipped into the flowing media in a rotating bin.

Read MoreHigh-Energy Barrel Finishers Efficiently Deburr Complex Parts

Mass Finishing Inc. has developed high-energy barrel finishers that automate the process of deburring complex parts, saving time and eliminating the need to deburr parts by hand.

Read MoreFeatured Posts

Shop Hands Over Gear Deburring to a Robot

Manual deburring of gears was an odious task for many of Katsa’s machinists, which in turn created a bottleneck that caused delays. The solution: a custom robotic deburring cell from Flexmill relying on Renishaw’s RMP60 probe.

Read MoreAutomated Part Deburring, Cleaning in One System

Palletized parts are transferred from a five-axis, high-pressure waterjet station to a cleaning station via linear motor to enable fast, automated finishing.

Read MoreDrilling and Chamfering Tool Solves Machine Shop's Vexing Problem

An oil & gas part with a lot of holes required that Utex use two different tools to ensure burr-free inner and outer diameters. With Heule’s Vex-S tool, the shop realized time savings per cycle of an entire minute by performing drilling and chamfering in a single step.

Read More4 Considerations for Electropolishing Machined Parts

Manufacturers considering this non-contact finishing process should expect test runs and close collaboration with service providers before production begins.

Read MoreApril 2019 Product Spotlight: Cleaning and Deburring

This month’s Modern Equipment Review Spotlight focuses on equipment used to remove imperfections from and clean finished workpieces.

Read MoreBack-Spotfacing Tool Frees Production from Costly Bottlenecks

By removing the need to detach and reattach the cutting head in a traditional back-spotfacing process, a cutting tool from Heule saved Sicom Industries two to three hours per part.

Read MoreFAQ: Deburring

What is deburring?

Deburring has traditionally been a manual task that takes place after machining to remove any remaining sharp pieces of metal.

What is a deburring tool used for?

A deburring tool is used to remove any remaining sharp pieces of metal necessary to achieve the desired finish. Deburring has traditionally been a manual task, but various technologies exist for reliably automating deburring.

.png;maxWidth=300;quality=90)