Software Provides The Edge For Toolgrinding

These days, software is increasingly providing the machining skills that once were the domain of experienced operators. This is especially true at cutter grinding shops where complex three-dimensional geometry, difficult materials, extreme tolerances and short lead times are typical.

These days, software is increasingly providing the machining skills that once were the domain of experienced operators. This is especially true at cutter grinding shops where complex three-dimensional geometry, difficult materials, extreme tolerances and short lead times are typical.

Tim Knapke, founder of Tru-Edge Grinding, Inc. (St. Henry, Ohio) started his business in 1993 with a few jobs from a former employer. "We started with regrinds and began to compile a large database of information about different cutters and what they do," says Mr. Knapke. "And that led us into manufacturing. Within a year we did our first dovetail, and since then we have been getting into increasingly complex processes for generating HSS and carbide cutters."

Today the growing workload at Tru-Edge is partly a result of a shrinking skill set in many companies. During the tough economy of the mid-1970s, most companies did not add personnel to the cutter grinding departments, and the remaining talent began retiring in the late 1980s and early 1990s. Few were left to train new operators. So today, many companies rely on a Tru-Edge to help them out, according to Mr. Knapke.

The backbone of the company's production capacity includes two CNC cutter grinders for manufacturing tools and a CNC cutter regrinding machine. "A six- to ten-piece manufacturing order is a big one for us, and we typically process 5,000 regrinds per month," Mr. Knapke says. "Manufacturing is 30 percent of our business and growing."

The company emphasizes the production of special, unique parts and troubleshooting tooling problems. "When a customer has an exit burr problem, for example," Mr. Knapke says, "we can identify what caused it, and we can eliminate the problem with proper cutter grinding. We find there is a lot more value to that than just putting an edge on a tool."

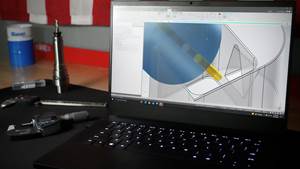

The desire to take a part print and design and manufacture a tool to complete a customer's part led Tru-Edge to invest in an off-line tool development program that enabled the efficient design of new tooling and the required manufacturing process without disrupting production. The answer was the CIMulator 3D cutter design and production software from ANCA, Inc. (Farmington Hills, Michigan).

With this software, customers can e-mail a .dxf or .dwg file describing their production part and tooling challenges. Tru-Edge then reverse engineers from the finished part print and provides a tool to create the part. The program shows the tool designer the exact shape of the tool to be ground on the machine and lets the designer examine the shape from virtually any perspective and to check each detail of the grinding process before the part is chucked in the machine tool. The position and direction of the cross-section can be changed in real-time by dragging it with the mouse, avoiding re-simulation.

The Cimulator 3D accuracy and reliability enables Tru-Edge to move quickly from CAD to grinding precisely the tool designed without missteps, trial cuts or wasted material, according to Mr. Knapke. "We get a true machine program directly from the tool design and simulation," he adds. Setup time for new tools is reduced, and production can begin more quickly.

As an offline workstation, CIMulator can also be run on the CNC to simulate tool production programs before grinding. "When I am designing a tool in the office," Mr. Knapke says, "I can simulate the grinding operation and make adjustments at the computer before the part program ever gets to the machine tool, avoiding trial cutting. I can then print off a sheet of what the tool for that job will look like or e-mail it to the customer for approval, make adjustments and then process the order."

The 3D Cimulator is essential to success at Tru-Edge. "It shows me exactly the tool the grinder will cut. It is the only software I have seen—and I've seen most of them—that enables the grinder to produce exactly what the simulator shows. The operator knows what he's making before the machine begins. We're enjoying setup times of literally only minutes, tool to tool, allowing us to process parts quickly. And it's allowed us to do work impossible otherwise. Recently, we produced a tool for an aerospace application that required us to grind 15 different radii along the outside diameter of the tool while following a helical flute form."

Tru-Edge is a specialist with the ANCA CNC tool grinding machines, regrinding and manufacturing with the TG7's and with OD grinders and centerless grinders. The TG7 does the fluting and finish work plus an RGX, which is designed for regrinding but can also do limited manufacturing.

"There are experienced operators who are good enough to do our type of work with old hard code," says Mr. Knapke. "They measure each individual tool, measure the index positions and do a hard program of the tool path. It takes them weeks to measure one tool, do the program and produce the tool. It takes me 10 minutes. Being able to turn around the cutters in days rather than weeks is particularly valuable to our automotive plant customers. Those production machining lines cost upwards of $5,000 per minute to operate and depend on the special tools we design and grind."

"We're not trying to be like everyone else. My goal is to help the manufacturing engineer who has a new part to make to concentrate on the machine tool while sending the job of creating the cutting tool to Tru-Edge. Many of our customers value that option," concludes Mr. Knapke.

Related Content

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreNew Machining Technology Works With Old to Restore WWII Submarine

A set of donated boring bars that can be used in a 1954 boring head will enable volunteer machinists to recreate a pair of binoculars for the USS Pampanito.

Read MoreHow to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More