There’s still a place for older machining technology, especially when it’s combined with new. A group of volunteers working with the USS Pampanito knows this well — they’re using a combination of new and old equipment, all donated by the machining community, to help restore the historic submarine.

The USS Pampanito is a WWII-era submarine that’s now a memorial and museum located at the San Francisco Maritime National Park Association at Fisherman’s Wharf. The submarine, which was stripped for parts and sits in corrosive salt water, is constantly undergoing restorations with the goal of bringing the ship back to its condition at the height of WWII submarine development. Photo Credit: Allied Machine & Engineering

The USS Pampanito is a U.S. Navy submarine that was built in 1943 and served six patrols in the Pacific during WWII. It was in storage through the 1950s, and was used for naval training during the 1960s. Eventually, the Pampanito was stripped for parts to repair other submarines. In 1982, it opened to the public as a memorial and museum, and is currently moored at the San Francisco Maritime National Park Association at Fisherman’s Wharf. Visitors and researchers can experience what life and war was like on a submarine in 1945, at the height of WWII submarine development, says Richard Pekelney, a member of the association’s board of trustees.

The process of restoring the historic submarine to its 1945 condition is a never-ending project, according to Pekelney. Not only is the Pampanito old, it also sits in corrosive salt water, so there are always parts that need to be repaired and replaced. In addition, the Maritime Park Association is working to recreate some of the parts that were lost when the submarine was stripped. This can be a challenge, but sometimes they’ll track down an old part they can reverse engineer, or find drawings for a part that they can then make themselves. The goal is to get everything functioning again at least one time, so that they know it’s been done correctly and can get it working again in the future if there’s ever a need or desire to do so.

.jpg;maxWidth=720)

The Maritime Park Association established a machine shop in a nearby building where volunteers repair, replicate and recreate parts for the Pampanito’s restoration. Equipment such as this Bridgeport milling machine and LeBlond lathe were donated by suppliers and machinists. Photo Credit: Richard Pekelney

In the mid-2000s, the Maritime Park Association established a machine shop in a building next to the submarine that’s dedicated to repairing, replicating and recreating parts for the Pampanito. All of the equipment and tools in the shop are donated by suppliers and other local machine shops. Currently, the machine shop has a range of manual equipment, including an old Bridgeport milling machine, a LeBlond lathe, a drill press and a variety of saws and grinding machines, plus tooling.

The shop is staffed with volunteer machinists, including Pekelney. He’s a self-described “computer science guy” who learned machining to assist with the restoration project. The onsite machine shop can’t handle all of the Pampanito’s needs (for example, larger runs of parts like screws that aren’t practical for manual machines), so local machine shops also donate machine time and material to the restoration project.

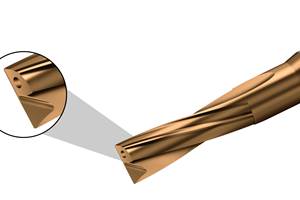

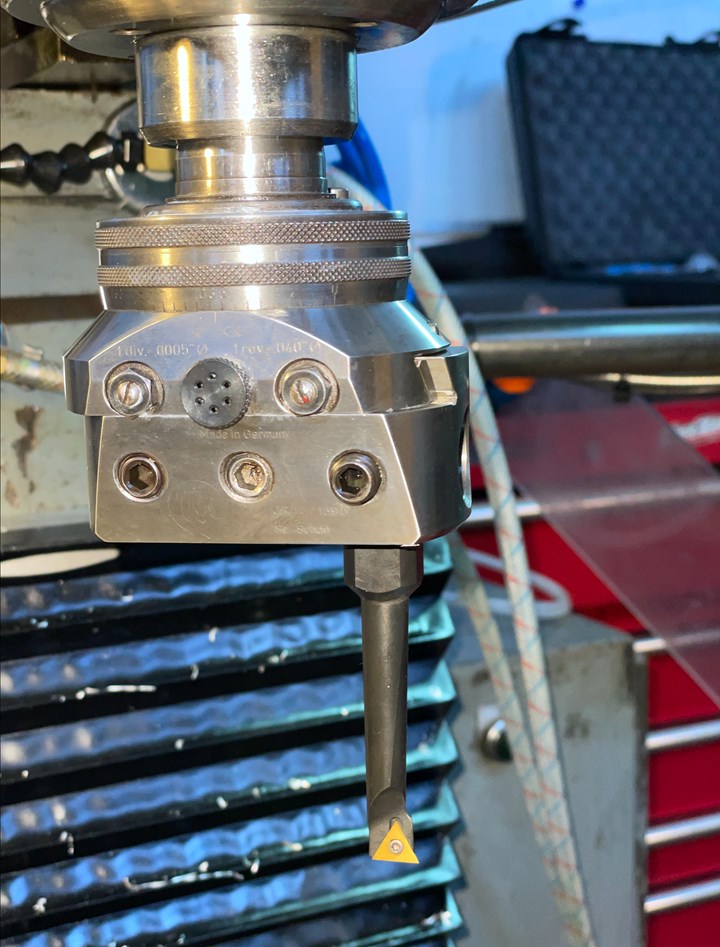

Donated by a local machinist, this 1954 Wohlhaupter boring head enables volunteers to face, recess, undercut and taper on the shop’s manual Bridgeport. Allied Machine & Engineering donated boring bars to use in the boring head, along with a conventional boring head and counter weights. Photo Credit: Allied Machine & Engineering

One of the Pampanito’s most recent equipment donations is a 1954 Wohlhaupter UPA 3 boring head from a local machinist. “The Wohlhaupter boring head makes it easy to face, recess and undercut on a manual milling machine like Pampanito's classic Bridgeport,” Pekelney explains. “It can even do some tapers.”

The shop needed a set of ¾" shank boring bars to go with the new head, so it reached out to Allied Machine & Engineering, which acquired Wohlhaupter in 2016. Allied went above and beyond, he says, and included ½" shank boring bars as well as and ½" and ¾" adapters that maximize flexibility to select the most rigid tool for the application. Allied also sent new Criterion-brand conventional boring heads, which he says will be “great for turning accurate inside and outside diameters on the mill,” as well as a set of balance weights that can be used with any of the boring heads.

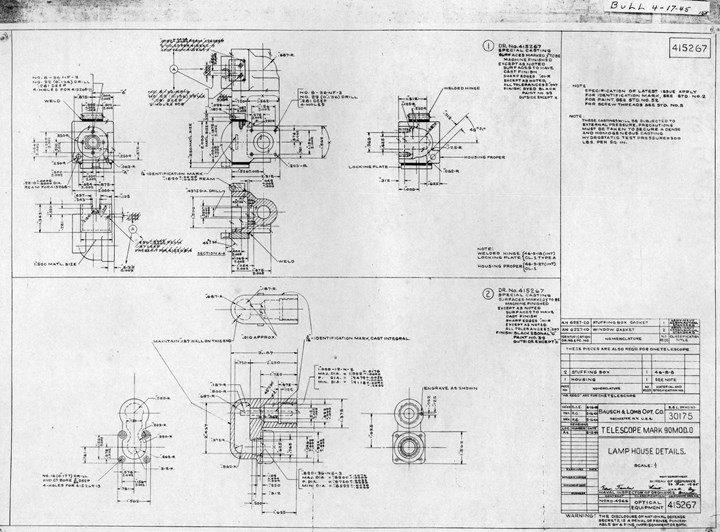

The first project using the donated boring tools will be recreating lamp housings for the Pampanito’s waterproof binocular sights, which enabled the crew to determine the size and distance of objects on the surface while the submarine was under water. The lamps for the binoculars were missing from the Pampanito, but recently found drawings have made it possible to create replicas. Photo Credit: Richard Pekelney

Pekelney says that the first project using these newly donated tools will be creating replica lamp housings for the submarine’s waterproof binocular sights. These binoculars stayed on the surface while the submarine dove 300 feet below the water. The lamps allowed the crew to see lines drawn up the side of the binoculars that they could use to determine how tall or wide an object was, and calculate its distance. These lamps for the binoculars were missing from the Pampanito, but recently found drawings have made it possible to create replicas.

Pekelney says that the generosity of the machining community has been vital to the Pampanito’s restoration. Donations like the one from Allied, as well as other suppliers and machinists, are enabling the association to preserve this piece of history.

Related Content

New Modular Tool Options for Small Spindle Milling

Tooling options have been limited for small spindle milling applications. Now modular, indexable systems are available that provide broad flexibility to get the right cutter for the job with less inventory and at lower cost.

Read MoreHow Lowering Torque Improves Tapping Tool Life

Escaping the tap breakage trap requires a long look at torque and the many factors that influence it.

Read MoreWalter Extends Line of Precision Boring Tools

The new boring tools employ modular components such as cartridge holders and extensions, which are matched to the system, utilize an extensive range of indexable inserts suited for precision boring and can be used for all material groups.

Read MoreWalter Launches New Solid Carbide Drill

The DC118 Supreme solid carbide drill provides high rigidity against deflection, superior centering accuracy and four margins with corner chamfers.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)