ZOLLER Inc.

3900 Research Park Drive

Ann Arbor, MI 48108 US

734-332-4851

zoller.info/us

About ZOLLER Inc.

ZOLLER is the global leader in tool presetting, measuring, inspection, balancing, shrinking, automation and tool management technology. The third-generation, family-owned company has provided state-of-the-art solutions for the complete management of cutting tools for more than 75 years.

IS THIS YOUR COMPANY?

Video Gallery

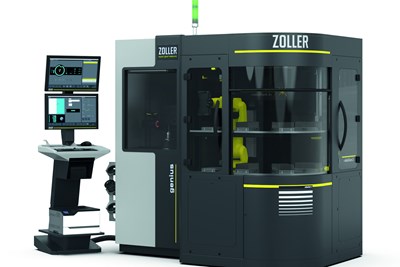

Measuring a concave radius on ZOLLER »genius« inspection solution | Tip of the Week

One of the challenges with measuring a radius on the inside of a cutting tool is detecting the exact portion of that arc. This video ...

How to measure an included angle on ZOLLER »genius« inspection solution | Tip of the Week

There are several ways to measure an included angle on a cutting tool, and ZOLLER offers measuring programs that work for all ...

Measuring diameter and taper on ZOLLER »genius« inspection solution | Tip of the Week

ZOLLER offers several measuring programs to measure the diameter and the back taper. In this video, we will demonstrate ...

Measuring intersection between 2 steep angles on ZOLLER »genius« solution | Tip of the Week

Measuring an intersection between two steep angles can be challenging. That's why ZOLLER developed measuring program ...

As Seen On Modern Machine Shop

ZOLLER Inc. Supplies the Following Products

Trade Names Offered by ZOLLER Inc.

- »zidCode« scanner

- »smartCheck« measuring machine

- »roboBox« automation solution

- »roboSet« automation solution

- »cora« collaborative robot assistant

- »coraMeasure LG« automation solution

- »venturion« presetting and measuring machine

- »toolBalancer« balancing machine

- TMS Tool Management Solutions

- »titan« inspection and measuring machine

- »smileCompact« presetting and measuring machine

- »smile« presetting and measuring machine

- »redomatic« presetting and heat-shrink machine

- »powerShrink« heat-shrink machine

- »pomSkpGo« inspection machine

- »hyperion« presetting and machine machine

- »hobCheck« inspection machine

- »genius« inspection machine

- »pomBasic« inspection machine

- »3dCheck« measuring machine