In CAM programming, it’s often the simplest tool paths that take the most time and trials to create. This is true even with advanced CAM systems. The various uses and special machining conditions only add to the difficulty, particularly in machinery, aerospace and defense applications in which not every tool path that clears the material on the CAM display is acceptable. In many cases, only a specific, user-defined path will do.

As a result, NC programmers still manually write and edit G/M-code programs. Programmers cite the flexibility and control that manual programming provides, versus the perceived rigidity of CAM systems. In CAM, the tool path you want is not always the tool path you get.

This desire for increased control is not lost on the CAM community. That’s why most CAM systems enable users to edit automatically generated tool paths. Usually, though, these edits are not associative. Hence, they are discouraged in the aerospace and defense industries.

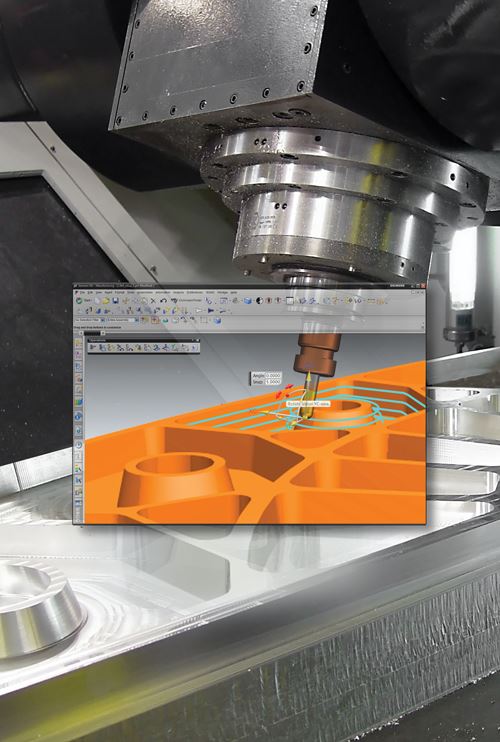

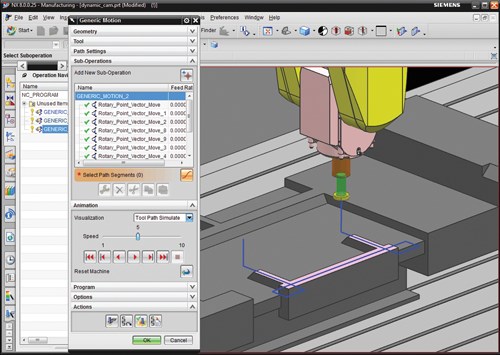

An alternative developed by Siemens PLM represents a very different way to define the tool path within CAM. The company’s Generic Motion Controller—part of NX CAM—is a virtual “teach” mode that enables the user to capture cutter locations by jogging machine axes within CAM.

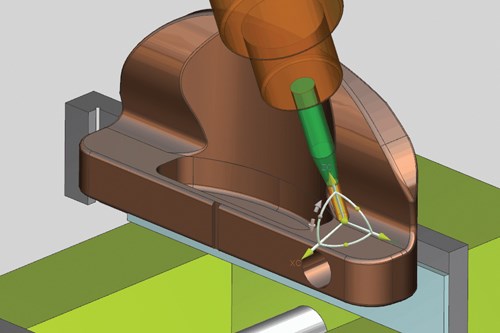

In this mode, the programming interface presents the user with an integrated simulation and verification model that includes the machine, cutting tool, part and fixture. To control the tool, the user employs a dynamic set of seven handles: one for the tool’s origin, three for moving the tool along each primary axis, and three for rotating the tool. By means of these handles, the tool is dragged within the graphic interface. The handles can also be snapped to “smart” objects on CAD models, such as a vertex, edge, midpoint of an edge or center of a circular edge. If a part revision changes one of these smart objects, the corresponding tool paths update automatically.

Programming in this way supports a variety of linear and rotary move types. A machine-position option lets users specify exact X, Y, Z, A and C values for addressing the tool. An upcoming release adds further sophistication. If the tool is positioned at a point on the part where it cannot fit, the software will automatically assign it to a tangent position to avoid gouging.

Onscreen graphical interaction with the cutting tool and part continues throughout the NX system. For example, to define a tool axis, the user positions the tool near the area to be cut and dynamically manipulates the handles attached to the tool display. For an interpolated tool axis option, the tool is shown at all four corners of the area to be cut along with dynamic handles. These handles can also be snapped to part geometry to preserve associativity.

Related Content

-

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

-

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

-

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.