Applying Creative Workholding Techniques

Not all parts can be fixtured by conventional workholding methods. Here are a few examples of ways that shops secure feisty workpieces for milling and turning operations.

A number of factors can contribute to difficulties in securing certain workpieces for machining operations. It may be that the workpiece material is pliable, causing it to distort using traditional clamping methods. Similarly, workpieces that have very thin features can have those features deform or even fracture because of clamping pressure. Contoured geometries also make it challenging to clamp certain workpieces.

There have been a number of innovative workholding methods that shops profiled in have adopted for such parts. In some cases, though, that neat workholding method may not have shone through as brightly as other shop improvement efforts because it wasn’t the main thrust of the story. That’s why we collected them here.

Even though your shop may not typically encounter the materials or geometries similar to the five examples that follow, these applications may spark an idea for a new or more effective way to secure a difficult workpiece you are currently machining.

“Lollipop” Workholding

The “lollipop” workholding method devised by Harmonic Drive LLC has roots in cutting tool technology. The Peabody, Massachusetts, manufacturer produces harmonic drives used for precision motion control and mechanical power transmission applications for various industries.

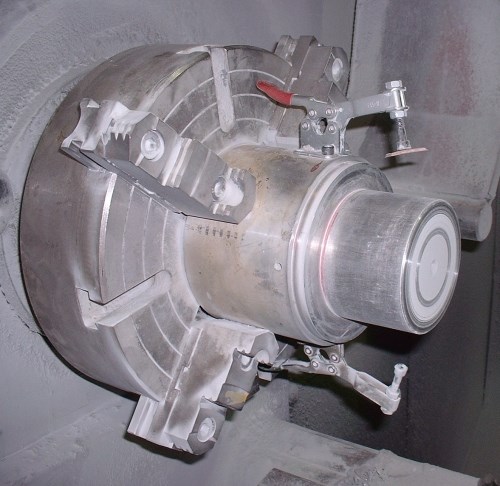

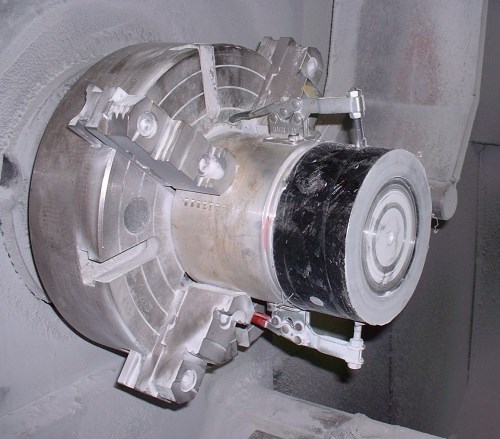

The shop needed to secure small, bell-shaped workpieces called flexsplines for turning, spline machining and OD inspection. The part, which begins as a 15-5PH stainless steel forging, first has its ID turned. This creates a wall thickness of approximately 0.06 inch. A final wall thickness of 0.01 inch is attained through OD turning. Because of the part’s shape and extremely thin wall thickness at this stage, it can’t be clamped in a lathe’s chuck. The thin walls would not provide adequate support during the turning operation.

The company had adopted Sandvik’s Capto as a quick-change tooling interface. To allay its workholding dilemma, it developed the idea to machine an arbor from a Capto boring bar blank onto which the flexspline can be mounted. However, because of the part’s bell-like internal profile, voids exist between the arbor and inner surface of the workpiece. To fill these voids, the shop pours a low-melt-temperature alloy through a bore down the center of the arbor. Once the alloy fills the voids and solidifies, the part and arbor bond together to become one. The alloy provides the internal wall support required to turn the part’s OD to the desired wall thickness. After all machining and inspection operations are completed, the alloy is melted away and the flexspline is removed from the arbor.

Got Tape?

Ron Thorn is the owner of Thorn Custom Guitars, located in Glendale, California. He uses the precision of CNC machining to help produce various wood components for his custom guitars.

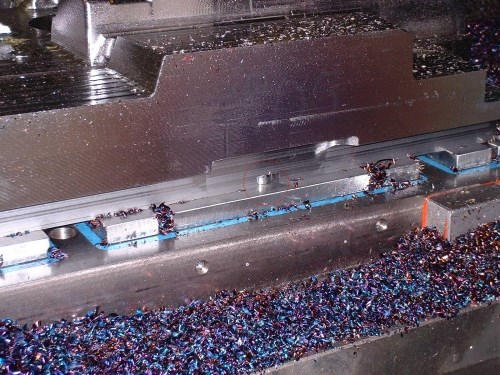

Mr. Thorn uses an uncommon workholding method—double-sided industrial tape—to fixture in the machine flat blanks of wood that will become fretboards, as well as inlay material used to adorn various guitar components. The tape, which measures 0.007 inch in thickness, creates a very strong bond between flat workpieces and the VMC’s tooling plate. The underside of the fretboard—the side that attaches to the guitar’s neck—is first face milled to flatness. Three dowel pin blind holes are then drilled into specific points on the fretboard. These holes locate the fretboard onto dowels in the tooling plate. Tape placed on the tooling plate hold the fretboard in place while various fretboard features are machined. The tape’s bond is so strong that acetone must be used to free the workpiece from the tooling plate.

Clamping Composites

Amalga Composites in West Allis, Wisconsin, specializes in producing fiber-wound products, such as drive shafts, rollers, pressure vessels and tanks. It winds or molds composite components, and machines those parts when necessary.

To support long, thin tubes for turning operations, the shop temporarily installs headers that are just a few thousands of an inch smaller than a tube’s ID into either end of the tube for chucking purposes. Shorter tubes that may require facing, drilling or turning are often mounted on a steel extension installed in the lathe’s chuck. Toggle clamps on the extension are used to hold the workpiece in place with sufficient force for the machining operation, but not too much force that could deform the part. To eliminate the chance that a tube’s inner surface might be scratched when held by its ID, the shop may simply apply a layer of duct tape over chuck jaws.

Atypical Application Of Magnetic Workholding

Anderson Pattern, located in Muskegon Heights, Michigan, is a 70-year-old pattern and moldmaking company that has started its lean manufacturing journey. The company turned to Wen electropermanent magnetic milling chucks in order to reduce set up times for mold components. Its goals were similar to other shops that have integrated magnetic workholding—quicker change-overs, better positioning repeatability and increased spindle uptime thanks to access to up to five sides of a part in one setup.

Some of the company’s large components fit the conventional profile of parts most commonly held by magnetic workholders—billets with ample surface area that the magnet can hold. Other parts, including smaller billets and castings, did not provide an adequate amount of surface area for the magnet to securely grip. Examples include wheel molds with a 1-inch-wide annulus on their bottom surface or blocks in which material was removed from their backside to reduce weight.

Parts such as these are prone to twist on a magnet during cutting operations, especially when cutting forces are directed parallel to the face of the magnet (which occurs when milling about a part’s periphery), compared to down toward the magnet (as in a drilling operation). An axial cutting force that’s only 1/18 of a magnet’s total pulling force on a part can cause that part to twist out of position.

To eliminate this tendency to twist, the shop uses dowel pins installed in key positions on pole extensions bolted to the magnet’s poles. The workpiece has mating dowel pin holes. By installing the workpiece on the pins and powering the magnet, the workpiece resists sliding and twisting during machining. Using dowel pins in such a way also provides a way to repeatedly position a part in all the shop’s machine tools and CMMs.

Fixturing Tall Blocks For EDM

Sometimes a shop’s efforts to fill a machining niche helps drive new product development. Such is the case with Extreme Wire EDM, located in Grandville, Michigan, which focuses on winning large mold work.

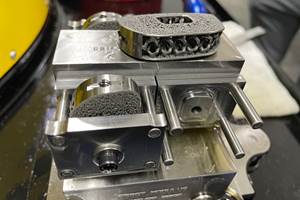

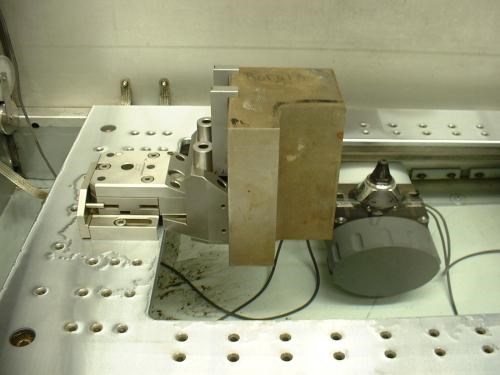

The shop uses a modular fixturing system from Hirschmann Engineering USA on its various wire EDM units. The system’s three main components are clamping unit, pallet and vise. The clamping unit secures to existing tapped holes located around the machine’s table. The vise jaws, which install in the pallet, clamp the workpiece. The pallet/vise/workpiece then locks into the clamping unit.

The shop has worked with Hirschmann over the years to develop taller vertical jaws to hold thicker workpieces. The latest jaws the shop has tested can secure workpieces as tall as 160 mm. Current versions can secure parts as tall as 115 mm and are rated at 66-pound capacity (though Extreme has installed parts as heavy as 100 pounds). Not only do the jaws secure large blocks for wire EDM, but they also extend the block into the center of the machine’s table to allow cutting heads a better chance of accessing the entire workpiece.

Related Content

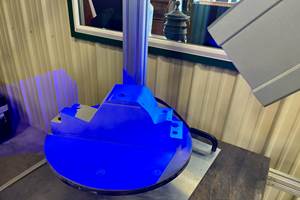

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreRead Next

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)