Medical Shop Demonstrates How To Manage Risk for ISO

The new ISO 9001:2015 standard emphasizes risk assessment. Medical shops like Protomatic with ISO 13485 certification already manage this.

Machine shops registered to the medical ISO 13485 standard have quality management system (QMS) procedures in place to effectively analyze, manage and mitigate production-related risks. So do AS9000-certified aerospace shops and most that serve the automotive industry.

Conversely, other shops registered only to ISO 2001:2008 (as well as those that aren’t) likely don’t have a QMS that formally addresses risk management. However, a certificate to ISO 9001:2008 will no longer be valid after the end of September 2018, and its ISO 9001:2015 replacement requires that shops establish procedures for comprehensive risk management. (Risk management represents one of a few significant changes in this revised standard that was published a couple of years ago.)

Failure mode and effects analysis (FMEA) is one common method of risk identification and mitigation, although it is sometimes referred to differently from company to company. Protomatic, a Dexter, Michigan, prototype machining and custom short-run production facility serving the medical, automotive, military and aerospace industries, refers to its as PFMEA—process failure mode and effects analysis.

Protomatic established its PFMEA methods years ago as part of meeting the requirements for its ISO 13485 certification. Doug Wetzel, company vice president, says the risk management procedures the shop has put in place might serve as a good model for other, non-medical shops that will be working toward becoming registered to the updated ISO 9001:2015, which is why he invited me to visit and learn more.

Identifying Then Mitigating Risks

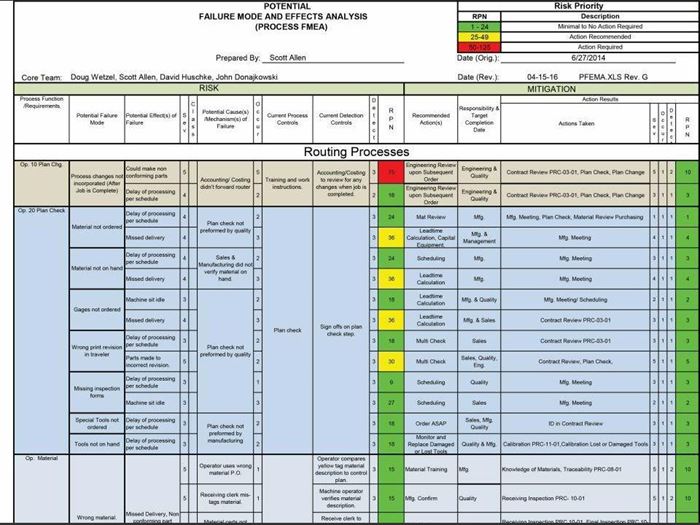

Mr. Wetzel says Protomatic’s PFMEA system is common to other medical shops, and a small portion of the generic PFMEA document he and his management team developed is shown in the slideshow above. Development of this document started with a management brainstorming session to identify all aspects of the shop’s operation (and those of outside vendors) that presented potential production risks, known as failure modes, that might result in non-conforming parts or assemblies. Then, for each of these failure modes, the team determined how severe the risk was, its potential frequency of occurrence and how difficult it would be to detect it.

In Protomatic’s case, it ranked the seriousness of each of these three factors on a five-point scale with 1 being minimal and 5 being maximum. (Mr. Wetzel says that other FMEA systems use a 10-point scale, but he notes that most medical companies are more familiar with the five-point scale.) For each failure mode, these three values are multiplied to establish a risk priority number (RPN). The shop established that an RPN ranging from 1 to 24 means the potential risk is such that no action is required, an RPN ranging from 25 to 49 means action is recommended, and an RPN ranging from 50 to 125 means action is required. These RPN values are highlighted in the PFMEA document in green, yellow and red, respectively.

Protomatic’s generic PFMEA document currently includes more than 300 potential failure modes. These are divided in sections related to internal machining processes such as milling, turning, deburring and blank sawing, as well as procedures such as job routing, inspection packaging and shipping. It also includes sections related to outsourced processes, such as passivation, plating and heat treating. This generic PFMEA document is then tailored to each specific customer job, because some jobs will not require all operations to be performed. It is also a living document. For example, if the shop was to bring in a new manufacturing process, such as Swiss-type turning, then it would have to add a section to its PFMEA listing all potential failure modes related to that process.

Risk assessment is only one part of the PFMEA method. As shown on the right side of the generic PFMEA document, Protomatic has identified ways to mitigate all potential process failure modes, with greatest attention paid to those that have RPN values of 50 or higher. Mr. Wetzel says that, in this respect, the PFMEA method enables the shop to establish solutions that are procedural or instructions-based prior to a problem emerging, rather than coming up with solutions on the fly after an issue arises.

For example, the section of Protomatic’s generic PFMEA document shown at the beginning of this article shows potential failure modes in the shop’s job-routing process. The initial failure mode listed relates to process changes not incorporated after a job is completed. One potential effect is the production of non-conforming parts when the job is run again. The severity of this failure mode is given a risk value of 5. The potential cause identified for this failure mode is the accounting department not forwarding the job router to engineering after job completion. This occurrence is also given a risk value of 5. Employee training and existing work instructions represented the company’s initial means for process control of this issue, and the initial detection method was for the accounting department to review any changes noted when a job is completed. The value for detection with respect to this failure mode is 3, bringing its total RPN to 75 and meaning immediate action was required.

The required actions the shop devised call for a review by the engineering department of each subsequent order for each job. Although the severity of this potential failure mode remains ranked at 5, because it could result in the production of non-conforming parts, the actions put in place to mitigate the problem reduced the occurrence value to 1 and the detection value to 2, reducing the RPN value for this failure mode to 10.

The portion of the example PFMEA document also shows that the shop doesn’t only work to reduce the RPN values of failure modes in the red zone that require immediate action. It also addresses potential failure modes that are in the green (no action required) and yellow (action recommended) ranges.

PFMEA’s Impact on Equipment Purchase Decisions

In some cases, the process of determining how to mitigate risks has impacted the decisions about what equipment Protomatic purchases. For example, the four VMCs it has most recently purchased from Haas Automation include tool presetting and touch-trigger probing systems. Scott Allen, Protomatic’s engineering manager, says all future VMC purchases will also include those systems.

The tool presetting probe is helpful in automatically measuring tools to speed setups and boost productivity. However, it is the spindle-mounted touch-trigger probe that has helped mitigate risks. Mr. Allen points to a job machining a very thin plastic cover for a medical device that requires milling to remove a molding defect. Depending on how those parts were packaged and handled after molding, they could become slightly warped, meaning the true location of the surface of a given part is unknown once fixtured on a machine. This led to machining repeatability issues that caused a high RPN value. To mitigate this, the shop programs the touch-trigger probe to locate a few points on the surface of a fixtured part and uses that data to adjust the machine’s coordinate system accordingly prior to machining, helping to ensure process repeatability.

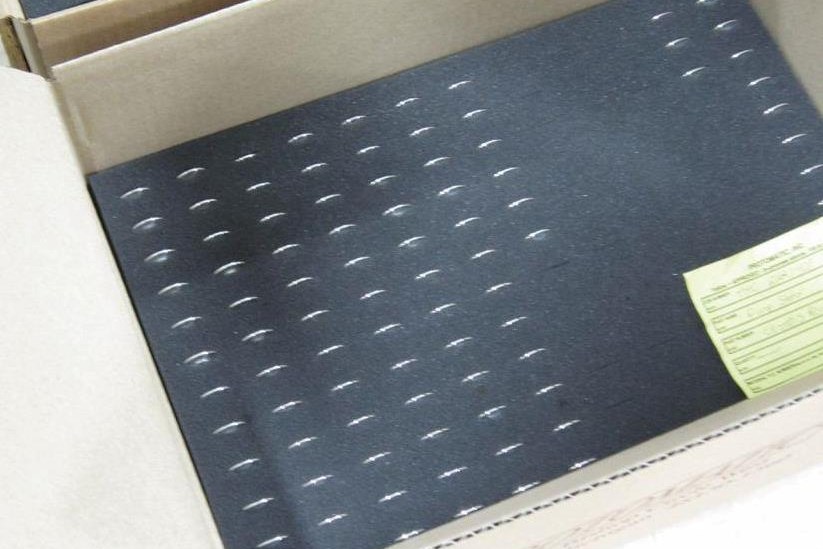

Protomatic has also introduced new technology to mitigate risks involved with tracking material received for specific jobs. “Although it is a rare occurrence, it is possible that the documentation for material received, be it on paper or via email, can be misplaced,” Mr. Wetzel explains. “In extreme circumstances, this could cause our customers to recall products if the material used isn’t the proper alloy.”

To mitigate this potential risk, the shop invested in a handheld Delta-brand X-ray fluorescence (XRF) material analyzer from Olympus. In less than one minute, the analyzer can detect the material alloy as well as all the elements that comprise it. A printout including this information is then included with the purchase order. Requiring XRF analysis of all material received reduced the RPN value for potentially receiving the wrong material for a job from 62 to 5.

Protomatic: Former Top Shops Winner

Efforts in establishing its comprehensive PFMEA method is just one example of why Protomatic was the 2015 Honors Program winner in the shopfloor practices category of Modern Machine Shop’s Top Shops benchmarking survey.

Mr. Wetzel says the shop analyzes the data compiled in the annual survey and compares that to its own specific data. “Even though most companies know their weaknesses, and likely have a plan in place to address those, the survey helps support a shop’s vision and confirms business direction,” he says.

In fact, this year marks the seventh edition of our annual Top Shops benchmarking program, which includes an annual survey with free data reports and an awards program. The online survey is now live and will remain open through February 28, 2016. Visit survey.mmsonline.com/topshops to participate.

Related Content

Beyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

Read More4 Ways 3D Printing Is Changing Medical Implants

Additive manufacturing provides new ways of making medical implants, but its impact is greater than this. How 3D printing is changing medical manufacturing and improving patient outcomes.

Read MoreModern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreThe Producto Group Appoints New Member to Board of Directors

Dean Schauer, the newest appointee to the company’s board of directors, is the current CEO and president of Confluent Medical Technologies.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)