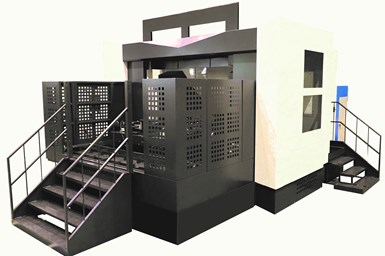

Niigata Engineers HN80E-5X for Maximum Rigidity

Niigata’s HN80E-5X Five-Axis Horizontal Machining Center features a heavy-duty construction that improves rigidity and part accuracy.

The HN80E-5X Five-Axis Horizontal Machining Center is the latest addition to Niigata Machine Techno USA Inc.’s heavy-duty HN-5X Series. The HN80E-5X features an impressive 49.2” of travel in the X-axis, 48.4” in Y and 47.2” in Z, and allows a maximum workpiece diameter of 49.2”, height of 39.4” and weight of 3,300 pounds. For increased rigidity, stability and accuracy, the HN80E-5X incorporates the solid cast iron X and Z base of Niigata’s HN100D-II Heavy Duty Boxway Horizontal Machining Center.

The simultaneous five-axis machining of the HN80E-5X improves cycle times and machined surfaces of complicated and 3D curved components. A quick and easy five-axis compensation function ensures high accuracy over extended periods. Five-face machining reduces the number of setups and simplifies fixtures for reduced changeover time. A servo motor drives the tool magazine for fast and reliable indexing.

As with all HN-5X machines, the guide ways of the HN80E-5X consist of a combination of hardened and ground hand-scraped turcite for long life, stability and vibration damping. The cross section of the rectangular guide ways is thick and wide for maximum machine rigidity. Niigata’s unique bifurcated bell-shaped column further contributes to rigidity and metal cutting efficiency.

The High Load Type Roller BRG and a Double-Lead Worm Gear System for low frequency machining support both ends of Niigata’s heavy-duty five-axis trunnion table. For consistent long-life dynamic machine accuracy, the HN80E-5X is equipped with an optical-scale feedback system (on X, Y and Z axes) and an inductive-scale feedback system (on the A and B axes).

A high-torque, heavy-duty spindle complements the rigid machine frame. The spindle head stock consists of mono-cast castings for more powerful milling and greater accuracy than bolt-together type spindle heads.

The HN80E-5X comes equipped with the FANUC 30iM controller. A variety of five-axis machining support software is available.

Related Content

-

Choosing The Right Grinding Wheel

Understanding grinding wheel fundamentals will help you choose the right wheel for the job.

-

Threading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

-

Choosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)