SolidCAM Wants to Help Machine Shops Get into Additive Manufacturing

Sponsored ContentSolidCAM's partnership with Desktop Metal is aimed at making additive manufacturing more accessible to job shops and other manufacturers.

Share

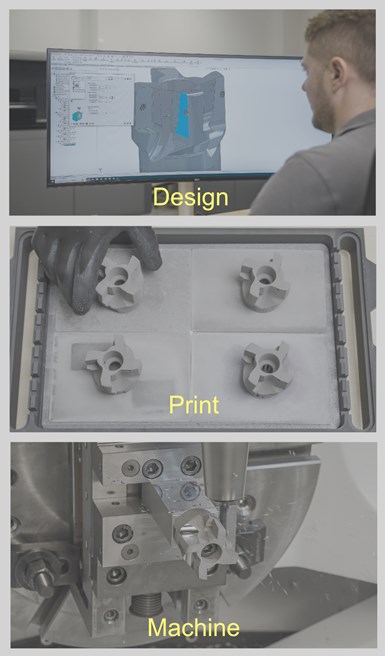

SolidCAM is enabling job shops to master the entire metal AM process, from design to printing to post-process machining.

If you're a job shop or other high-mix machining operation, sooner or later you're going to have to consider bringing additive manufacturing into your production capabilities portfolio. If you're in the prototyping business, you already know that. But AM is becoming increasingly relevant in low-to-medium volume production. Shops that don't have it will grow increasingly uncompetitive for many jobs.

Leading CAD/CAM developer SolidCAM wants to help make the journey to AM easier. According to Founder and CEO, Dr. Emil Somekh, "SolidCAM views additive manufacturing as a complement to our 24,000 CNC subtractive manufacturing customers worldwide. The ability to print complex metal parts, with speed and repeatability, is now within reach of even the smallest job shops and we have committed to becoming a leading resource in this space for our SolidCAM CNC customers.”

Deeper Knowledge Through Partnership

What does that mean? First, SolidCAM has formed a partnership with Desktop Metal to leverage its metal binder jetting technology. Desktop Metal's Shop System is the first such AM platform specifically designed to bring metal 3D printing to machine shops. Dr. Somekh says that Desktop Metal has invested heavily in simplifying a complex process to allow for increased productivity and throughput of parts, with limited operator involvement.

Both companies recognize that taking on AM involves much more than dropping a metal 3D printer on your shop floor. There is a full slate of issues that come with building an internal AM infrastructure such as:

- How to pick the right AM applications.

- How to manage the total metal AM process – from file preparation to printing and curing parts to post-process machining.

- How to design parts for AM.

- How to optimize the total process and ensure that the highest throughput and quality standards are met.

A big problem for job shops exploring AM has been that vendors tend not to sufficiently appreciate the demands of a job shop environment. They need to quickly find process solutions for a part and execute production expeditiously at an acceptable cost. For precision parts, AM alone only gets you halfway there. Because SolidCAM already works with job shops every day, they understand the needs and can help guide shops to an art-to-part process that makes sense, and that makes money.

Integrating the Entire CAD to Part Process

SolidCAM's integrated approach to CAD/CAM provides a significant advantage. Its CAM functionality runs inside the widely used solid modeling packages Solidworks and Autodesk Inventor, both of which have robust design-for-AM capabilities. This frees users to apply the best design tools while leveraging the same 3D model for sophisticated CNC programming functions such as SolidCAM's well-regarded iMachining and Advanced Mill-Turn. The company is also developing a new module for hybrid machines where 3D printing and machining occur on the same platform.

This penchant for integration meshes well with Desktop Metal's holistic approach to AM from the creation of proprietary metal powders to the sintering of parts in its advanced Furnace solution and the first-of-its-kind Live Sinter application. Live Sinter uses a multi-physics engine capable of simulating the complex forces and deformation that parts experience during sintering, and automatically generates "negative offset" geometry which, when sintered, results in straight, defect-free parts.

In additive manufacturing, as well as machining, technique can be as important as technology, and SolidCAM intends to help job shops with both. To that end, SolidCAM has set up new CNC + AM Centers of Excellence in Pennsylvania, Germany, and the U.K. Additional facilities are also in the works in California, Israel, and India. The service centers will teach shops how to implement AM technology and even produce parts for companies not quite ready to make the full commitment. Says Dr. Somekh, "Through combining the two technologies, companies can solve complex engineering problems in new and innovative ways. Metal 3D printing will still need post-processing with CNC machining to ensure the parts are to the finish specifications the customer requires. SolidCAM is positioned as the leader in CAM solutions, adapting its software technology to effectively post-process the growing market of additive parts."

Please visit the website to learn more about SolidCAM Additive Manufacturing Solutions.