Tool Line Complements Titanium, Stainless Techniques

A notable trend over the past five years or so has been the evolution of techniques for machining hard, difficult-to-cut materials, particularly titanium and stainless steel.

A notable trend over the past five years or so has been the evolution of techniques for machining hard, difficult-to-cut materials, particularly titanium and stainless steel. Driven by demand in the burgeoning aerospace and medical sectors, one approach that has gained traction involves CAM software tool paths designed to keep tool engagement constant in a high-feed approach with shallow radial cutting depths.

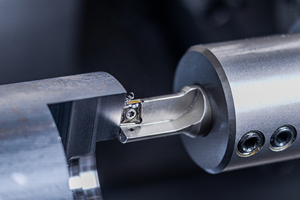

Of course, similar to other manufacturing strategies, efficiency depends on more than a single element in the process (the tool path in this case). As such, developments in one area tend to lead to developments in another, and this is no exception. Among the suppliers offering milling tools designed to work with these tool paths is IMCO Carbide Tool (Perrysburg, Ohio). In a recent conversation about the cutting tool manufacturer’s newly reengineered EnDuro line of end mills, company president Perry Osburn revealed some basic insights about key design considerations for such cutters.

First, however, a note about the strategy—the primary advantage of keeping tool engagement constant throughout the cut is that it avoids sudden changes in direction that cause the load on the tool to fluctuate. For example, the tool load increases dramatically when entering a corner, often resulting in premature wear. Keeping a constant load enables even lighter, lower-horsepower machine tools to effectively machine hard materials, Mr. Osburn says.

Expected to enter full production this month or next, EnDuro encompasses five different types of end mills that cover the gamut of machining methods, from the new high-feed techniques to traditional strategies. One feature common to those designed for constant engagement tool paths is a higher number of flutes. At the lower radial cutting depths that characterize constant-engagement tool paths, more flutes are needed to achieve sufficient metal removal. Of course, the tool must move faster across the workpiece as well—hence the high feed rates common to this strategy.

Another important factor is flute spacing. EnDuro end mills are designed with variable edge spacing, which means the flutes are not evenly spaced around the tool. Some amount of vibration is produced each time a flute hits the workpiece. Flutes that are evenly spaced produce vibrations at regular intervals—vibrations that essentially feed off one another and make the problem worse. Irregular flute arrangement alleviates this effect, providing improved balance, smoother, more precise cuts and longer tool life, Mr. Osburn says.

Naturally, including more flutes means less space between the flutes, which can cause problems with chip evacuation. (Titanium, especially, is a poor thermal conductor, so driving heat away with the chip is of great concern in this material.) That’s where the form of the flute itself comes into play. While remaining tight-lipped on specifics, Mr. Osburn says minute adjustments—invisible to the naked eye—in how the angles and other geometric features are formed helps optimize chip evacuation. Coatings such as AlTiN, a common choice for titanium, also aid in resisting heat.

One key consideration in this area is the relief angle, which is engineered to keep the flank of the tool from banging against the side of the workpiece as the cutting edge passes through it. A proper relief angle is key for cutting titanium, which tends to "push" away from a tool rather than shearing cleanly, Mr. Osburn says.

Similarly, the effectiveness of the cutting edge also depends on minute adjustments during honing and micro-finishing. The intent is to ensure that the edge doesn’t break down when the tool enters the cut. "When the tool contacts the workpiece, it forms a little wear land on that edge," Mr. Osburn explains. "What we and other manufacturers try to do is pre-form that wear land during edge preparation."

However, the high-feed, constant-engagement technique is only one of many strategies for machining titanium and stainless steel. As such, the EnDuro line also includes tools for more traditional techniques, including a five-flute end mill designed for heavy hogging at high radial cutting depths. A shop might choose to rough with this tool before finishing with the EnDuro high-efficiency mill or seven-flute mill, or it might cut the entire part with one of the latter products using constant-engagement tool paths. "The intent is to have a family of tools that pretty much any shop could use to machine titanium or stainless," Mr. Osburn concludes.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreNew Modular Tool Options for Small Spindle Milling

Tooling options have been limited for small spindle milling applications. Now modular, indexable systems are available that provide broad flexibility to get the right cutter for the job with less inventory and at lower cost.

Read MoreChoosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read MoreCeratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)