What Capabilities Do You Need for Medical Machining?

Sponsored ContentMachining orthopedic implants, instruments and tooling places special demands on machining centers. Here’s what to look for to achieve the highest quality and most efficient machining processes.

Share

Read Next

Machining parts for the orthopedics industry is demanding. Whether it’s joint implants, surgical instruments, molds or forging dies, the materials are difficult, the geometry is complex, and the quality standards are second to none. Moreover, the business grows more competitive by the day, and manufacturers must be both technically proficient and production efficient to remain viable suppliers to this market.

Well known machine tool builder Makino has specialized in serving the medical industry for many years, and along the way has acquired a great depth of process knowledge in 3D machining of common medical industry materials such as titanium alloys, cobalt chrome, and stainless steel, as well as hard tool steels 60 HRC and beyond. Here’s what Makino recommends to produce these difficult parts to the highest levels of quality and efficiency.

Achieving High-Quality Surface Finishes

Achieving dimensional accuracy is important to a point with orthopedic implants but the biggest challenge is usually the surface finish. For this reason, post-machining hand finishing is still usually required with belt grinding, polishing and buffing. And it’s time consuming. These finishing processes can take 45 minutes for a single part. Unfortunately, no practical machining process today eliminates the need for hand finishing of these parts, but a high-performance machine and stable machining process can dramatically cut that time and machining cycle time as well.

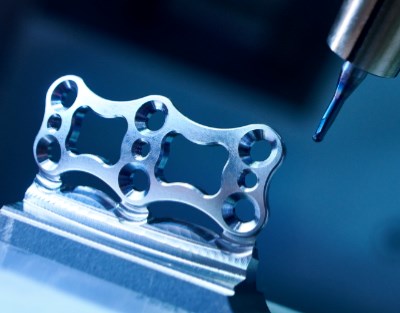

This titanium alloy bone plate is machined on a DA300 machining center in just over 22 minutes. Machining 4 parts in a setup reduced total cycle time over 12%.

How do you do that? Improved surface quality can be achieved through the combination of engineered cutting parameters and proper toolpath strategies. For example, on a performance-based machining center, moving from a 25 Ra surface finish up to a 32 Ra could reduce your cycle time by 50% for a femoral implant, providing consistent, predictable results. Providing a precise and predictable surface finish allows end users to develop more efficient and effective secondary finishing processes, which can reduce these operations by as much as 50%.

To help find the sweet spot of machine time vs. finishing time, Makino application engineers have developed strategies that look first at the required output surface finish and then create machining parameters accordingly. That, of course, could be done with any machine. But to move the needle to a more efficient process overall is to apply machining technology that is very fast, accurate and stable over long process runs so you can reduce finishing without having to pay a heavy penalty in machining time.

Five-Axis Machining is a Given

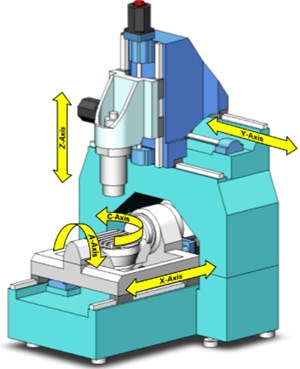

Generating 3D part and tooling shapes common in the orthopedics industry essentially dictates the need for five-axis machining. This can be accomplished with a 3-axis mill fit with a tilt/rotary table in a 3+2 configuration, but there typically will be a sacrifice in speed, surface finish and precision compared to a fully integrated five-axis machine.

On a good two-axis auxiliary table, you might typically see positioning accuracy of ±3-5 arc sec. and 30 to 50 rpm in speed. By comparison, Makino’s DA300 five-axis machining center, which is used widely in the medical industry, uses direct drive servo technology on its tilt/trunnion table and can achieve positioning accuracy and repeatability of ±2 arc. sec. on the tilt and a contouring speed of 100 rpm. The rotary axis is accurate to ±1 arc. sec. and can achieve 150 rpm. Combine that with X-Y-Z axes that can feed up to 1968 ipm and a 20,000 rpm spindle and you have a much more capable platform for high speed 3D machining.

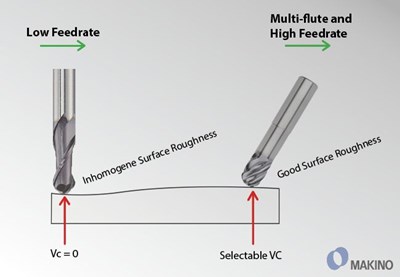

On the left, trying to cut with the tip of the tool where there isn’t any velocity. By tipping the tool, you use a larger portion of the of the diameter to get good cutting conditions.

Being able to accurately feed and articulate the tool to workpiece so quickly also enables much more efficient use of cutting tools. With simultaneous five-axis machining you can maintain a constant tool vector to a 3D workpiece surface, which with a ball nose end mill should not be a vertical orientation. When feeding a ball mill vertical to a workpiece surface, you are essentially dragging the tip of the tool across that surface at zero rpm, which is hardly an efficient cutting process.

By tilting the tool relative to the surface you utilize the effective flute length, of the tool efficiently. This effectively increases the surface footage of the tool and can boost metal removal rates by as much as 40-50%, yet still generate better surface finishes and blends.

It’s also important not to scrimp on the quality of the tooling. Precision ground tools generate less vibration to produce better surfaces, and last longer too. Toolholders are also extremely important to minimize tool runout, which also degrades tool life and finish quality. For high speed machining in these difficult materials, a shrink fit may not be mandatory, but it is recommended. You can get a payback in the range of 20% improvement in tool life.

Critical CNC Functions for 3D Machining

It’s this combination of rigidity, speed, accuracy and freer cutting action that renders a machining process much more capable of efficiently generating surface blends and matches with dramatic reductions in cycle time and post-machining finishing work. However, this increased machining speed and multi-axis freedom of movement create two new concerns. How do you reduce the risk of tool collisions at high feed rates? And how do you manage the tool path so that you actually achieve the quality surfaces that you think you programed in CAM? Makino addresses these concerns with additional software features available on its Pro 6 control:

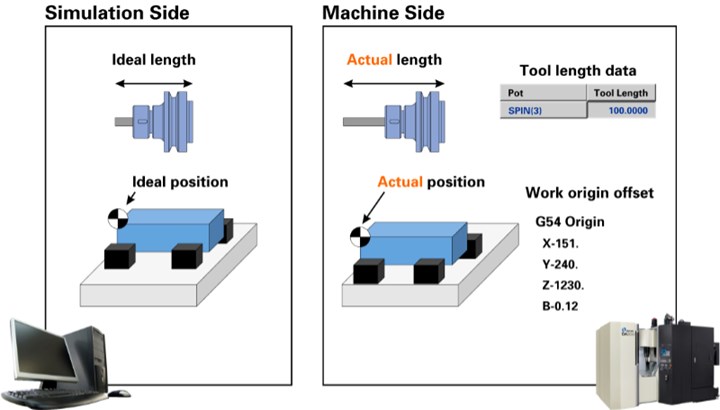

Collision Safe Guard (CSG) – Because of the dynamic nature of moving both the spindle and the workpiece in a five-axis environment, unintended tool, workpiece and fixture collisions are a real danger. For this reason, it is recommended that a full solid model simulation of the part program be done in an application such as CGTech’s Vericut. Makino’s proprietary Collision Safe Guard (CSG) then takes that model a step further and replicates the full simulation in the machine control, also taking into account the workpiece and tooling offsets and other physical setup alterations made at the machine. The actual workpiece, fixture and tool features (length and diameter) can easily be discovered with an automatic probing routine. Then the software looks ahead in the part program, and when collision points are detected, it shuts down the machine before a crash occurs.

With Collision Safe Guard, you import a part program simulation into the Pro 6 CNC; then CSG applies actual tool and workpiece offsets, and looks ahead in the program to discover any interference issues with the real world setup. It then stops the machine before a collision occurs.

SGI Smoothing – There are a variety of factors that can mar the surface finish of a workpiece: dwells, axis over-shoot/under-shoot, sudden axis stops and reversals, vibration and more. Makino’s proprietary Super Geometric Intelligence (SGI.5) software mitigates these conditions by providing optimum feedrates that generate higher quality surfaces while also reducing cycle time.

SGI can maintain high feed rates based upon a blend of chordal tolerance, block length, number of points, look-ahead and M-codes, establishing tolerances to maintain higher feed rates even during abrupt directional changes in the tool path. Rather than having to program for the worst-case scenarios, you can establish a faster feed rate and the control will automatically compensate where corners or intersections could compromise the accuracy of the cut. Or, in applications using high feed milling techniques, this capability will better ensure the actual toolpath is sustained at the programed feed rate.

This comparison shows the quality of surface finish without (left) and with SGI Smoothing. See full size image.

Maintaining Process Stability

Symmetrical machine design is an important factor in mitigating the ill effects of thermal distortion. Also important is providing equal support across the entire axis travel ranges, as show in this rendering of Makino’s DA300 five-axis machining center.

It is one thing to machine to high standards under optimal conditions, but quite another to do it all day long and over extended periods of time. For successful medical machining, that means achieving process stability that is maintainable without undue human intervention. Two critical and interrelated factors here are the inherent geometric accuracy of the machine and the thermal stability of the machine.

Common practice for machine tool builders is to address geometric inaccuracies in the machine with electronic compensation in the control. For example, say the run of an X axis isn’t perfectly straight or there is pitch, yaw or roll as the axis traverses from one limit to the other. These inaccuracies can be mapped and compensated for in the CNC’s motion. However, this methodology can become increasing unstable as the machine heats up because the compensation may no longer be accurate in a state of thermal distortion with some machines.

Rigid workholding is an important factor in achieving low-vibration process consistency, and can be challenging with the organic workpiece shapes in medical machining.

Makino’s answer for this is to build machines with symmetrical designs that minimize thermal distortion and apply active thermal management systems to keep the machine thermally stable in the first place.

A variety of factors combine to deliver high positioning accuracy (±0.000060") in the DA300 and other models designed for medical machining, including core-cooled, fine-pitch ballscrews with 0.05 micron scale feedback. The high-speed spindle enables fast machining of fine features with small tools. The spindle is also thermally controlled providing optimum performance over extended periods, ensuring exacting cutting conditions from start to finish to produce tight-tolerance, high-quality workpieces.

Stable Processes Enable Unattended Machining

Today’s medical manufactures are under increasing pressure to become more efficient without sacrificing quality. Doing that effectively requires investing in more capable equipment, which, of course, comes at a cost. From a financial perspective, the top companies are thinking much more like high-volume production manufacturers with greater consideration of factors such return on investment, equipment utilization rates and labor costs. You can’t just be good at making parts anymore; you must also be efficient to be successful as a business.

Once process stability is achieved, it becomes possible to automate medial parts machining. Shown here is Makino’s DA300 integrated with an Erowa automatic pallet changer.

Makino’s background in production machining is very helpful in this regard as they bring this thinking to how they approach medical manufacturing solutions. It’s not just about machining 3D surfaces faster and to higher standards, though that is indeed important. It’s also about compressing the total time to manufacture medical parts and getting the most out of your considerable investments in technology and skilled people.

It’s little surprise, then, that automation is becoming increasingly common in leading medical manufactures and that Makino’s five-axis machining centers are all designed for easy integration with both third party and Makino-built automation solutions. For example, the DA300 and other 5-axis machines are designed to integrate with Erowa’s robotic loading systems. These systems can bring high production-like efficiency to an orthopedics manufacturing shop, even the ability to machine unattended. That’s a great way to maximize five-axis machining processes plus get the most out of your technology and people. It’s also a great formula for building a very profitable medical manufacturing business.

Go here for more information on Makino’s DA300 or their entire line of Vertical Five-Axis Machining Centers.