Master Fluid Solutions Introduces Emulsion for Grinding and Cutting Operations

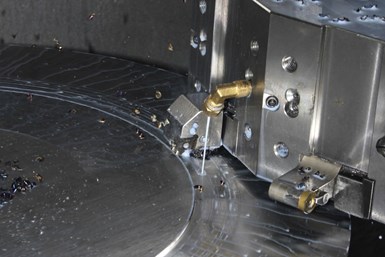

Trim E860 is said to be an ideal solution for heavy-duty and general machining.

Master Fluid Solutions announces the newest emulsion to join their signature North American Trim line, Trim E860. The fluid is said to be compatible with a broad range of ferrous and nonferrous metals and adept in both grinding and cutting operations. The new product is designed for precision parts manufacturers, as well as any customers looking for consistent performance.

With a balance between lubricity and cooling ability, E860 is said to be an ideal solution for heavy-duty and general machining. It also meets the needs of manufacturers utilizing a wide range of materials and operations. The long sump life formula is free of biocides, phenolic compounds and sulfur for easy disposal and wide material compatibility, as well as being able to perform optimally in hard water environments. E860 is naturally resistant to tramp oil and maximizes separation in the sump for easy removal, reducing overall fluid maintenance times. During use, the fluid leaves a light residue to prevent corrosion.

“Trim E860 is the perfect addition to our family of emulsions, providing excellent reliability and finish quality for a wide range of drilling, milling, turning and tapping operations,” Justin Geach, global OEM/MTB and NA NBD manager says. “The fluid offers a tight emulsion for low carry off and excels in heavy-duty operations on all materials, offering excellent tool life and surface finishes.”

Related Content

-

Rego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

-

Jorgensen's Coolant Collection System Eliminates Sludge Build-Up

The PermaClean system adds agitation to the coolant collection system or holding tank and prevents particulates from settling.

-

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.