Quick Fixture Changing System for Heavy-Duty Machining

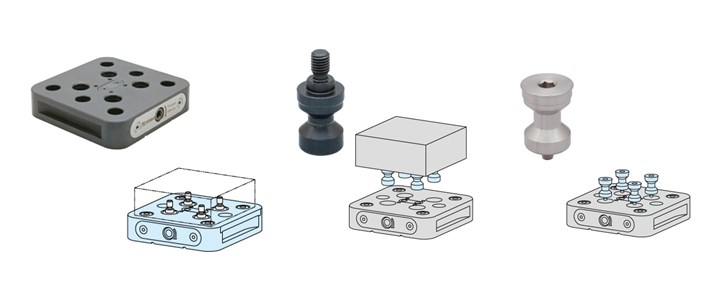

IMAO Fixtureworks' Flex Zero clamping system reduces downtime during fixture changes. It is designed for quick change of pallets, workpieces and vises in five-axis and vertical machining centers, and the strong clamping forces enable heavy-duty machining.

IMAO Fixtureworks, a manufacturer and supplier of workholding components, has introduce a new mechanical zero-point system, Flex Zero, for clamping and precision locating in a single operation.

With one tightening operation on the side of the base, four-point clamping is achieved by two jaws. The jaws locate and clamp the pins for precise and fast fixture changes, which is said to reduce machine downtime during fixture change operations. The compact Flex Locator Bases are available in 150 mm and 240mm sizes with +/- 0.005 mm repeatability and 2,700 lbs of clamping force.

Designed for quick change of pallets, workpieces and vises in five-axis and vertical machining centers, and the strong clamping forces enable heavy-duty machining. With the pull clamp design, the clamping pins are attached to the underside of the fixture plate, which IMAO Fixtureworks says maximizes space on the fixture plate for multiple workpieces.

IMAO Fixtureworks manufactures and supplies a wide range of industrial products that range from modular fixturing components and workholding devices, including clamps, workholding gripper inserts, supports and locators, to standard machine elements, including pins, material handling rollers and bumpers, fasteners, adjustable handles, cam levers and more.

Related Content

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.