Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Reader Question:

We’re receiving a lot of orders where a custom workholding solution is required. Some ideas have worked, but others required more trial and error. Do you have some ideas to help us develop more effective solutions when a vise or soft jaw simply won’t work?

Regardless of the material, shape or tolerance of the part, there are some basic tenets every good workholding solution should follow.

First, the fixture should be easy for the operator to load, and difficult for them to load incorrectly. We want to set up a scenario where the operator can be as successful as possible. This means a consistent quality grip on the part, and possibly doing so quickly in a production scenario. Things like poka-yokes are important for proper part orientation and should be used. Do your best to make them clever and simple. It should not be an excessive burden to the operator where they may feel compelled to bypass them.

Second, the fixture is designed with the part print in mind, but also optimized to reduce the number of set ups. Ideally, every fixture will use fixed locators of some type for critical datums to rest against. This ensures mechanical repeatability for positional tolerances. Realistically though, this can sometimes force us into more operations. Therefore, use hard datums if you can, but use the machine probe or an in-process tolerance as needed to reduce part handling and still maintain tolerances.

Lastly, the clamping should be strong enough for roughing operations, but also limit distortion imparted on the part. You should be thinking about how clamping forces will impact the part as a raw billet, and when it is finished and weaker. The challenge is to clamp the part where it is strong and with enough force that it doesn’t move away from critical datums during heavy roughing, while also soft enough that it won’t distort the geometry of the weaker, finished part.

Sticking to these tenets will greatly improve custom workholding success, but they are not actual solutions, they are simply rules to live by. The actual workholding solution can take on infinite forms and all would be correct to some degree. Therefore, without seeing your specific parts, here are some ideas I would consider as you work on your designs or improve upon them:

The most obvious is modulating how much force you use to clamp the part. If the part is at risk of movement, consider more clamping force. If it is at risk of distortion, do the opposite. This could be using a torque wrench to limit the holding force of each clamp and create consistency from operator to operator. It can also mean that multiple clamps on the same part don’t necessarily need to hold the part with the same force. If you can get a better grip on the part in a stronger area, take it and limit the amount of force on a weaker area.

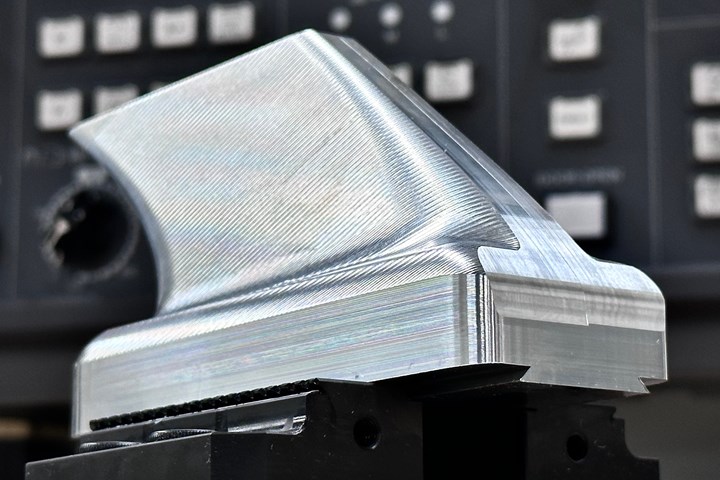

Consider the shape that we touch the part with. This applies to the clamp and the locator. This could be a point load or spread over a wider area. A smaller clamp point load may penetrate the surface of a softer metal and then provide some mechanical locking on the part. Or, if you’re trying to reduce deformation, consider a wider surface to reduce localized distortion. In either case, the same overall clamping force can yield very different results.

Equally important is the direction that we apply the force. Ideally, all forces should be pushing into a hard stop of some type. But if you are concerned about the part lifting, you could take a sideload and instead come from the top or an angled force to equally push and trap the part.

Often, workholding is smooth metal on smooth metal and no matter the amount of force, a part can still slide. This is where friction can be your friend. This can be done with grip tape, laser texture or a serrated clamp. In each case, we increase the effective holding force with the same amount of clamping force. Distortion is not increased, but part movement during machining is greatly reduced.

If you believe you’ve optimized all the above as best you can, but are still struggling, there are two troubleshooting techniques I like to use when diagnosing a fixture issue. First is putting a dial indicator on the part and watching its movement in critical areas during the clamping process. The movement could be shift in the part as it nests itself into the fixture, or it could be distortion imparted by the clamping forces or direction. Second is utilizing the machine probe to track movement of the part throughout the machining process. You can set up a quick positional check of a known feature at the beginning of the process, then after the bulk of the roughing. Based on the results, if you believe there to be part movement, you can then get more granular and run the same check tool by tool to find the culprit and adjust the magnitude of the forces (feed, depth of cut) or the direction of the forces (into hard locators versus away) as needed.

Custom workholding is not ideal for most job shops simply because of the cost and time and risk involved to develop a solution for such a small number of parts. Even in very high-volume production, a custom solution is necessary, but costly and risky as there’s only one chance to get it right. In either case, the best chance for success and mitigating risks is a well thought out plan. Follow the tenets, be creative and be ready for some troubleshooting for the highest chance of success.

Related Content

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreMoving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)