SETCO

2255 Global Way

Hebron, KY 41048 US

800-543-0470 | 513-941-5110

setco.com

IS THIS YOUR COMPANY?

Video Gallery

SetcoRunOffRoom

Setco Spindles.

Setco- SEGVideo v4 Spark Erosion Grinding

Setco SEG 125 Spark Erosion Grinding - the industry standard to machine honeycomb seals and rings for jet engines. The Setco ...

Kessler Spindle Runoff

Kessler Spindle Runoff - 24000 rpm, HSK63 spindle.

Franz Kessler spindle repair during Tool orient testing.

Franz Kessler spindle repair, during Tool orient testing closed loop on Siemens drive.

As Seen On Modern Machine Shop

SETCO Supplies the Following Products

Trade Names Offered by SETCO

- SETCO

- MASTER

- SETCO / MASTER

- MASTER / SETCO

- FlexCenter

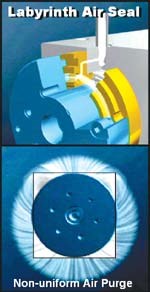

- AirShield

.jpg;maxWidth=400;quality=90)