Additive Manufacturing and 3D Printing in Metalworking

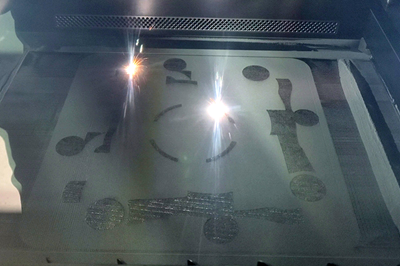

Additive manufacturing (AM) refers to the application of 3D printing to create functional, industrial components including prototypes, tooling and end-use production parts. AM’s advantages include the freedom to produce small batches of intricate parts cost-effectively, as well as the freedom to realize part designs that would not be manufacturable in any other way, and in some cases to use materials that otherwise would be impractical to apply. The range of processes finding industrial applications includes direct metal deposition, electron beam melting, polymer processes such as fused filament fabritcation (FFF), and select laser sintering (SLS) or melting (SLM), among others. Some hybrid machine tools combine additive manufacturing with subtractive CNC machining. Modern Machine Shop has a sister magazine, Additive Manufacturing, that focuses on AM.

ESSENTIAL READING

VIEW ALLGo Digital: How to Succeed in the Fourth Industrial Revolution With Additive Manufacturing

The digitalization of manufacturing is set to transform production and global supply chains as we know them, and additive manufacturing has been leading the way in many industries.

Read More4 Ways 3D Printing Is Changing Medical Implants

Additive manufacturing provides new ways of making medical implants, but its impact is greater than this. How 3D printing is changing medical manufacturing and improving patient outcomes.

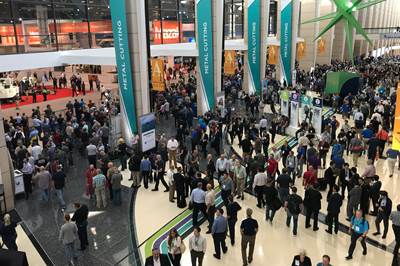

Read More5 Tips for Getting the Most From the Historic Return of North America’s Biggest Manufacturing Event

Plan. Explore. Think of the future. And oh yeah, the shoes. Here is how to get the most from the major manufacturing event that none of us have experienced in four years, and that many will be experiencing for the first time.

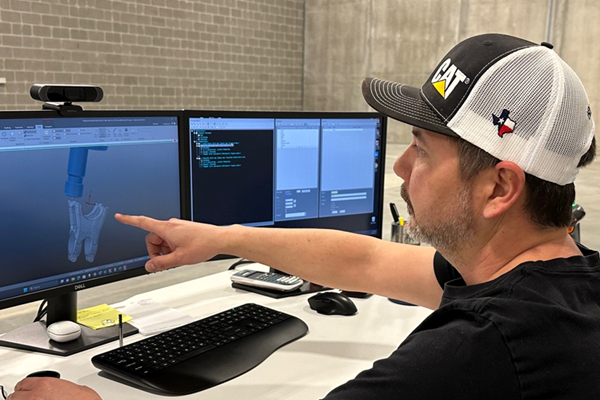

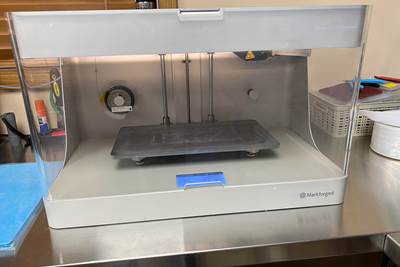

Read More3 Uses for a Composite Polymer 3D Printer in a CNC Machine Shop

When RPG purchased its metal 3D printer, a polymer printer was part of the deal. Three uses this job shop has found for this fused filament fabrication system.

Read More4 Ways Robots and 3D Printing Intersect

Four examples of how robotic automation and additive manufacturing both help and are helped by each other.

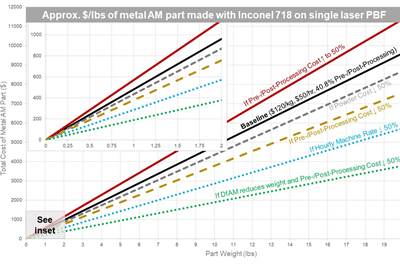

Read MorePlotting a Pathway to Profitable Additive Manufacturing

The cost per pound for a metal AM part may be shocking, but that knowledge is essential to plan a journey to success with Additive Manufacturing.

Read MoreLatest Additive Manufacturing News And Updates

JTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

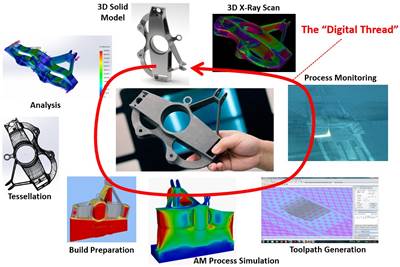

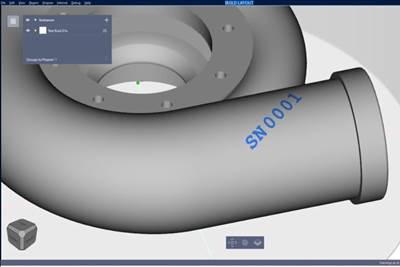

Read MoreDigital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

Read MoreVelo3D Software Enhances Control Over 3D Printing Process

The software’s new features include user-selectable core parameters, preprint analysis to identify potential costly and time-consuming errors, and rapid resequencing for multipart prints.

Read MoreUltiMaker 3D Printer Supports Production Applications

The printer features a temperature-controlled heated build chamber and heated build plate, enabling users to print large production parts with manufacturing-grade ABS.

Read MoreVolkmann Depowdering Station Removes Toxic Materials

The Volkmann additive manufacturing technology is designed to safeguard workers and boost efficiency.

Read MoreFeatured Posts

5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

Formnext Forum: Austin, a two-day event at the end of August focused on additive manufacturing for production, includes a conference exploring important ideas in AM related to supply chains, bridge production, enterprise transformation and more.

Read MoreThe Cool Parts Showcase Seeks Innovative 3D Printed Parts

Do you solve problems with 3D printing? Enter your 3D printed parts in this contest from The Cool Parts Show.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreA Fond Farewell to My Additive Friends

In his final “Additive Insights” column, Tim Simpson reflects on how additive manufacturing has progressed in the last six years. Standards and software are two examples.

Read MoreGo Digital: How to Succeed in the Fourth Industrial Revolution With Additive Manufacturing

The digitalization of manufacturing is set to transform production and global supply chains as we know them, and additive manufacturing has been leading the way in many industries.

Read More4 Ways 3D Printing Is Changing Medical Implants

Additive manufacturing provides new ways of making medical implants, but its impact is greater than this. How 3D printing is changing medical manufacturing and improving patient outcomes.

Read MoreFAQ: Additive Manufacturing

What is additive manufacturing?

“Additive manufacturing” (AM) describes the use of 3D printing to make functional components, including tools and end-use production parts. Unlike “subtractive manufacturing” processes such as machining, where parts are created by removing material, additive manufacturing builds geometries by “adding” feedstock such as filament, wire or powder.

Depending on the 3D printing process and application, additive manufacturing can utilize a growing catalog of materials including metal alloys, thermoplastics, thermoset polymers and composites.

Source: What is Additive Manufacturing?

Is additive manufacturing the same as 3D printing?

Some say yes and we say no! AM and 3D printing are overlapping terms but not synonyms. 3D printing is the operation at the heart of additive manufacturing, just as “turning” or “molding” might be the operation at the heart of a conventional manufacturing process.

In a nutshell, 3D printing is one step in an overall additive manufacturing workflow that also includes design, build preparation, postprocessing, business considerations and more.

Importantly, “3D printing” does not describe just one type of technology. Per ISO/ASTM, there are seven different “families” of 3D printing processes and a growing number of material and machine options.

Source: What is Additive Manufacturing?

Why use additive manufacturing?

Some associate AM with prototyping, but this is outdated. 3D printing has become well-established as a means of creating tooling for a range of conventional processes. And, manufacturers are increasingly adopting AM for production, including full-scale production.

Source: What is Additive Manufacturing?

What are some trends in additive manufacturing?

- Artificial intelligence and machine learning.

- Decentralized or distributed manufacturing.

- Robots and automation.

- Simulation.

- Sustainability.

Source: What is Additive Manufacturing?

What is Formnext Chicago?

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois.

Formnext Chicago is part of a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

Here is the full lineup of Formnext events in North America:

- Formnext Forum Austin took place in August 2023 and will return to Texas in 2026.

- Additive Manufacturing Sector Powered by Formnext at IMTS in 2024

- Formnext Chicago in 2025

Additive Manufacturing Supplier Categories

- for Ceramic Parts

- Material Extrusion

- Ceramics

- Training & Consultancy for Additive Manufacturing

- Job & File Management Software

- Vat Polymerization

- for Metal Parts

- Part Design Software

- Directed Energy Deposition

- Safety Equipment for Additive Manufacturing

- Sheet Lamination

- Material Handling Equipment

- for Polymer Parts

- Part & Tooling Production Services

- Composites

- Powder Bed Fusion

- Postprocessing Equipment

- for Composite Parts

- Polymer

- Binder Jetting

- Hybrid AM Machines

- Material Jetting

- Metal

.png;maxWidth=300;quality=90)