Workholding

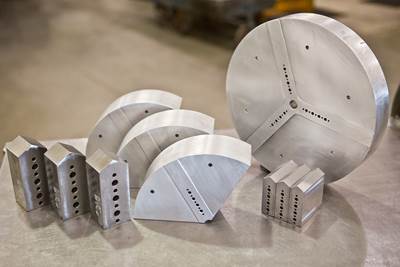

Dillon Reversible Hard Jaws Provide Secure Parts Gripping

The company’s reversible hard jaws are designed to decrease the time and cost of tool setups.

Read MoreDestaco Electric Power Clamps Enable Flexible Production

The 92W series electric power clamps feature integrated intelligence to reduce the need for additional components.

Read MoreDillon Pin Location Jaws Hold Sensitive Parts Without Deformation

Each jaw is CNC milled to provide maximum accuracy of workpiece location, enabling air chucks to hold sensitive workpieces firmly.

Read MoreStafford Shaft Collars Enable Adjustments Without Tools

Stafford shaft collars and mounts feature handles and thumb screws to convert standard shaft collars to quick-adjust types.

Read MoreSMW Autoblok Vise System Provides Omnidirectional Clamping

The Plus5 V5 Zero Point Vise system interfaces with all industry-standard products using 52 mm or 96 mm pin spacing, enabling it to readily become part of existing workholding systems.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreFixtureworks Pneumatic Clamping Locators Reduce Setup Time

The AMWF-W and AMWF-L pneumatic clamping locators are zero-point systems, enabling quick, precise clamping.

Read MoreCeratizit Product Update Enhances Cutting Tool Solutions

The company has updated its MaxiMill 273-08 face mill, WPC – Change Drill, as well as the HyPower Rough and HyPower Access 4.5-degree hydraulic chucks.

Read MoreFairlane Workholding Components Enable Modular Positioning

Fairlane Products Inc.’s Swivots workholding components swivel, pivot and tilt to compensate for angles and irregularities of the workpiece.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

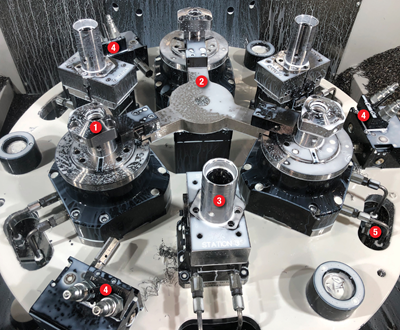

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read More