Medical Machining

Medical Machining refers to all of the CNC machining related to surgical implants, orthotic devices and medical instruments. Challenges include small-scale machining or micromachining, because implanted devices often consist of very tiny components, and machining titanium, a material often used in medical devices because of its non-reactivity with the body. Efficient small-batch machining of complex parts is also important because new medical devices are developed quickly and refined through many iterations. Moreover, for implantable parts, shows must receive FDA approval of their machining processes.

Latest Medical Articles

VIEW ALLKyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

Read MoreTungaloy-NTK PCD Grade Optimizes Dimensional Accuracy

The DX200 is an effective tool for machining application-specific components that demand high levels of material purity, such as metal medical implants and sputtering targets for semiconductor applications.

Read MoreThe Producto Group Appoints New Member to Board of Directors

Dean Schauer, the newest appointee to the company’s board of directors, is the current CEO and president of Confluent Medical Technologies.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreEDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreGF Machining Solutions Plans to Open New Medical Manufacturing Facility

The new center will provide medicamanufacturers with applications support and production technologies, including precision milling, EDM, laser texturing, micromachining and automation

Read MoreLatest Medical News And Updates

Ametek EMC Laser Cutting System Offers Through-Part Cooling

The new laser cutting system offers comprehensive Swiss machining capabilities, as well as through-part cooling and automatic part-handling options.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read More4 Ways 3D Printing Is Changing Medical Implants

Additive manufacturing provides new ways of making medical implants, but its impact is greater than this. How 3D printing is changing medical manufacturing and improving patient outcomes.

Read MoreANCA Introduces Tool Loading System for Medical Drills

ANCA’s dental drill loading kit includes tailored RoboMate pallets for FX machines using a FANUC 200iD robot loader.

Read MoreYCM Alliance Hits IMTS

YCM Technology has joined with other like-minded machine tool manufacturers to take a solutions-based approach to manufacturing.

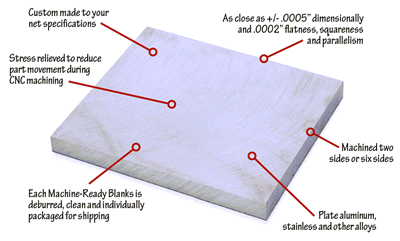

Read MoreMachine-Ready Blanks Help Shops Reduce Setup Time and Scrap

Machine-ready blanks from TCI Precision Metals are designed to help shops shorten setup time and reduce amounts of scrap. These blanks are ready to ship but can also be custom ordered.

Read MoreFeatured Posts

Beyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

Read MoreView From My Shop, Episode 2: 3D Printing and Postprocessing With Tangible Solutions

Collaboration between Tangible Solutions’ additive and machining departments simplifies their work. Learn more in this episode of The View From My Shop.

WatchFive-Axis and Clever Controls Support Medical Manufacturing

Kern’s Micro Vario and Heidenhain’s TNC 640 control give M5 the precision and accuracy it needs to successfully micromachine medical parts.

Read MoreIncrease Profitability 17% with Exporting

This short tutorial will empower you to find the right market for your product, ensure you get paid, and provide resources to get started. (Sponsored)

WatchHigh-Pressure Coolant System Reduces Cycle Time More Than 6 Hours

A suite of systems from LNS has enabled Velco Tool & Die to reduce cycle times and increase its throughput.

Read MorePutting People First: a Profitable Strategy

Treating people fairly and valuing their contributions isn't only the right thing to do. It’s also a direct path toward greater profitability, as shown by this Top Shop.

Read More

.png;maxWidth=300;quality=90)