June 2001 Issue

June 2001

Features

Featured articles from the June 2001 issue of Modern Machine Shop

Technology Makes Machine Shop A Success

This month's column features Modelwerks, Inc. , located in Seattle, Washington.

Read More

Training Time

The graying of skilled metalworkers adds impetus to the growth of standardized training programs.

Read More

The Dynamics Of Better Drilling

Vibration is at the heart of a variety of common problems in machining holes. Mathematical analysis is helping to bring about a better understanding of hole-making processes...including how these vibrations behave, and what steps to take to bring them under control.

Read More

Reclaiming The Hole-making Process

A shop that had been farming out hole-making operations on oversized components brought this work back in-house after acquiring a large-format, CNC drilling machine. The process now can be done more quickly, at lower costs and on schedule, with many workpieces machined as assemblies instead of separate pieces

Read More

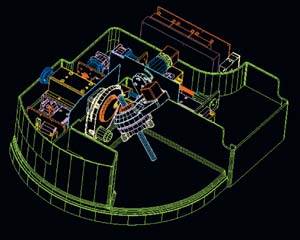

Multi-Axis Drill Sharpening Made Easy

Today, metalworking is privy to some very remarkable performances by the combination of things mechanical and things electronic--mechtronics. We've seen the reality of lights out shift operations. Programming systems that make what was state of the art 5 years ago seem like writing with a hammer and chisel. An example of the melding of mechtronics is this new drill sharpening system.

Read More

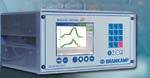

Monitoring Devices Head Off Disaster

Whether you are a job shop running one-of-a-kind parts or a large manufacturing plant producing parts by the hundreds of thousands or millions, a machine tool crash can mean missed deliveries, lost production time and expensive repairs. The chances of such crashes are increasing as companies strive to get maximum utilization from their CNC machines by running them 24/7.

Read More

Virtual Tools For Real Training

In machine shops across the nation, operators increasingly rely on virtual part data instead of blueprints. Given their prowess in manipulating three-dimensional objects and simulating mechanical operations, why couldn't computers also be used to provide aspiring metalworkers with their own pre-flight training?

Read More

Looking Beyond Inspection

For this shop, the only fly in their ointment was quality inspection. When the shop first started producing parts in the summer of 2000, punched blanks had to be sent a few miles up the road, where quality technicians could check setups with a coordinate measuring machine. The round trip could take as much as 2 days.

Read More