September 2014 Issue

September 2014

Features

Featured articles from the September 2014 issue of Modern Machine Shop

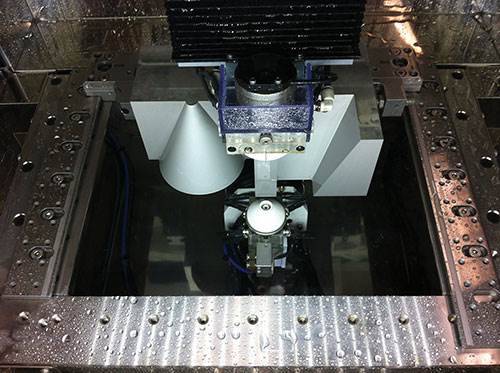

Ultrasonic-Assisted Machining with Standard Machines and Tools

A system to be marketed in 2015 will apply ultrasonic vibration from within the toolholder to reduce cutting force and improve the performance of the cut.

Read More

Swiss-Type Lathe Features Integral Laser Cutter

An integral laser cutter brings another capability to this multifunction machine platform.

Read More

From Media to Manufacturing

Video producers with no previous knowledge of CNC discover the power and possibilities of modern machine tool technology. Their example says something about where manufacturing talent might come from, and also about the importance of manufacturing as a whole.

Read More

What It Takes to Be a Top Shop

Leading machine shops share signature traits. This year’s Top Shops benchmarking survey reveals what some of those traits are.

Read More

Start with the Specs

Techspex has a new website and new capabilities. In place of a word-based search engine, this free utility aims to be the logical starting point for searches aimed specifically at finding the right machine tool.

Read More

Improvement Is Not Optional

No matter how busy this shop gets, it continues to pull teams of employees out of production so they can focus on solving problems to make incremental process changes. The advances add up. Today, this is a very different shop than it once was.

Read MoreThe Secret Robot

A manufacturer struggles over its employees’ potential reaction to automation. The struggle itself says something important.

Read More