Considerations for Adding CMM Capabilities to Your Shop

CMMs may provide simple efficiency gains, but if you look deeper, the machine unlocks more complex work for your shop.

Reader Question:

Our shop has grown from making boutique products to now doing prototyping and production. We see an important role for the coordinate measuring machine (CMM) in our operations. How do you view the implementation of a CMM for a growing shop? What are some of the requirements you foresee and when would you implement it?

Miller’s Answer:

Purchasing your first CMM can be a difficult decision for any shop. Personally, I am nearing this decision point in my own operations, but even after purchase it can be a challenge to implement properly. I’ve said in a previous article that capital equipment purchases can achieve three main goals: Do more of the same type of work (for example, a second VMC), do new types of work (for example, a new five-axis) or make current work more efficient (for example, automation). Most shops view the CMM as the latter, as it makes measurement more efficient. However, I’d challenge shops to view the CMM as the second and think about the CMM as an entirely new capability to realize its full potential.

Adding CMM capabilities is a challenge for some shops. After all, measurement in our industry is a given, so why spend so much on something to check the same things that you already do with calipers and micrometers and height gauges. The point of the CMM is that it’s gathering several data points all at the same time. When it checks a bore, it’s measuring size, position and roundness all at the same time, and saves these data points for later use.

This might look like a simple efficiency gain — which it is — but if you look deeper, a CMM unlocks more complex work for your shop. It was probably not the machine, the talent or the CAM system holding back your shop from trying more complex work. It was the ability to properly verify the combination of all these skills that a CMM achieves.

Another capability that the CMM unlocks is volume. You may have the best QC staff on earth, but only so much work can be achieved in a 24-hour period on a surface plate. Automating your measurement process means QC can better keep up with the machines making parts. Issues are found as they happen, data is kept to understand trends and suddenly the jump from small-lot prototypes to full-scale production volumes seems much less scary.

Lastly, the CMM delivers consistency. As a machinist, I can appreciate just how repeatable our systems can be. If we put care into the setup, the tools and the programs, a machine will run its program largely without flaw day and night. Why not remove the last source of human error from that system by utilizing a CMM? Even when just utilized for simple tasks like measuring holes, a CMM can eliminate chordal error and parallax error.

There are several technical considerations when implementing a CMM for the first time. Knowing them now and preparing for them will hopefully save a lot of effort during implementation. There are the obvious things like learning probe selection, proper calibration of said probes and programming/alignment. As a person on the metal cutting side, I’ll allow a measurement expert to comment on those. However, from my perspective, there are some mistakes I see that you’ll want to avoid. The first is trusting the CMM too much at the beginning. It’s easy to do given its overall accuracy and capability, right? Remember, as you’re learning the CMM, mistakes will be made just like a new machinist whiffing on an offset adjustment. You can rub the shank of the probe on the part and get an erroneous reading or make a mistake with the datum structure that throws all positions out of tolerance. Therefore, if you think a measurement is bogus, it might be. Double check your program, watch the probe take its points and be sure to keep the hard gauges handy. Don’t overreact to a bad part until you can confirm the CMM readings.

The most successful implementation of a CMM mimics all the things you already know about your machining centers. And like your machining center, there is money involved in all these steps. Plan accordingly for not just the price of the machine, but cost associated with implementation.

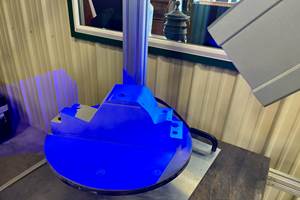

From there, it’s straightforward. Like many metal cutting machines, CMMs require a certain type of pad to sit on. They need an adequate power and an air supply. Finally, much like your CAM system for the machine, the CMM needs software to drive it.

The most overlooked part of implementation is the environmental controls. A properly clean, relatively cool and well-ventilated area is a must to host the CMM. We are asking the CMM to be substantially more accurate than the CNC in order to measure parts with the proper scrutiny. While you may not need a dedicated room, just understand that anything you do to improve the conditions will assist in your measurement consistency and long-term success.

To put a final thought on whether the time is right to for you to invest in a CMM, I would answer these questions. Are you committed to treating this as an asset and a new capability? Do you have a team willing and capable of proper training and implementation? Does the expenditure make sense monetarily? If the answer to all three is yes, then now is the time. Beep!

Do you have a machining question? Ask the expert. John Miller leans on more than a decade of industry experience to answer machining questions from MMS readers. Submit your question on the form webpage.

Related Content

Determining Out-of-Roundness at the Point of Manufacture

George Schuetz, Mahr Inc.’s Director of Precision Gages, offers these techniques for measuring roundness on the shop floor.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreChoosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)