From Manufacturing Circle To Victory Circle

For some time now, this manufacturing company has focused on optimizing engine performance by making ports as efficient as practical so as to reduce turbulence and improve air flow.

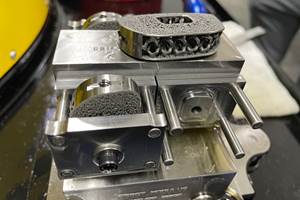

Airflow Research is a Los Angeles-based company that manufactures aluminum cylinder heads and related parts for the high performance automotive industry. For some time now they have focused on optimizing engine performance by making ports as efficient as practical so as to reduce turbulence and improve air flow. Better air flow means more air/fuel mixture into the cylinder, an increase in combustion efficiency, and more effective exhausting of burned gases, which in turn creates more horsepower.

The problem was this: The company used to do all of their cylinder head porting by hand, with an electric grinder. It took a highly skilled individual up to 40 hours to do the job. They knew the alternatives would be to machine the ports to the desired shape and finish, but the free-form surfaces were just to complicated for any of the affordable CAD/CAM systems, and the very high-end systems were difficult to use.

Until they got into CAM, all of their two- to four-axis tool paths were done by manual code writing. The heads had to be positioned at different angles in order to reach and machine undercuts from different directions. It took hours of trial and error. But today, this same job takes only eight hours and part-to-part repeatability is greatly improved.

Finally, when they acquired the ability to digitize finished cylinder head port designs using probes and software, they needed a useful way to manipulate and process the data. Their primary focus was to digitize cylinder heads, import the data into a CAD/CAM system, create surfaces from those digitized points, and generate programs to machine a variety of port designs.

After interviewing several leading mid-range CAM companies, they chose SURFCAM for its ease of use, speed and power. One thing that made a great impression was Surfware's commitment to offering solutions to their specific problems (for example, posts for strange and unique applications) as well as excellent customer support.

Implementation of normal two- to five-axis surface machining was said to be a snap. However, any time you are dealing with digitized data and trying to create surfaces to be machined simultaneously using five-axis, you are dealing with a learning curve that is nearly vertical.

Having a CAM system has allowed Air Flow to generate their own tooling for their foundry. Previously it was subcontracted out, but with the in-house capability, they have more control over design and manufacturing process. Increased accuracy yields castings that require less final machining time.

Using SURFCAM's Verify feature they can pre-run all of their programs graphically, identify any problems, and make the necessary corrections before they get to the machine tool. This means they don't have to use expensive machine time to prove that the tool paths were correct. The former is profit, the latter is overhead.

Air Flow uses a Haas five-axis HS1R horizontal machining center (HMC) to machine the cylinder heads, and for full five-axis porting work. They also have a Millac 2 three-axis (manual fourth and fifth) HMC, a Mori Seiki Mv35/40 four-axis (manual fifth)vertical machining center (VMC), and a Fadal 6030 five-axis VMC.

The Haas machine provides true simultaneous five-axis machining, in a stable environment because it has an integral fourth axis, and a Haas rotary table for the fifth axis. Many five-axis machines stack two rotary tables one on top of the other for the fourth and fifth axes.

The eight megabytes of memory in the Haas control will actually accept about a 12-megabyte program created off-line on the SURFCAM system. That's because the Haas control strips out all the line feeds, spaces and other unnecessary information. The control executes up to 1,000 blocks per second, an important feature for true simultaneous five axis machine motion. In addition, it considers the whole line of code—defining X,Y,Z,A, B and feedrate—as one block. Because SURFCAM creates simultaneous five-axis code, and the Haas control executes it efficiently, many functions are enabled that are locked away inside the machining center's control, giving them more efficient programs and shorter run times.

Gary Tripp started with Air Flow Research working with manual machines. Today, he is called upon to design and implement new manufacturing methods.

Related Content

Best Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreBuilding a 5-Axis Cell

5-axis machining has taken over the metalworking industry, but what goes into a high-functioning 5-axis machining cell?

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)