From Solid Models To Solid Machining Performance

Efficient model importing and toolpath generation help this shop deliver accurate parts more quickly.

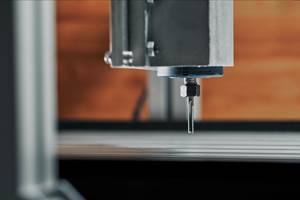

Innovative Precision LLC., located in Ogden, Utah, specializes in tool making, prototyping and production machining for medical, aerospace, military and automotive customers, providing short-run, high-precision machining services. Housed at its facility are a four-axis wire EDM, a sinker EDM, an EDM drilling machine, three CNC turning and four three-axis milling centers. Two of the mills and one lathe were added in the last year alone.

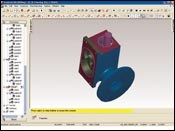

To provide services in a timely and accurate manner, the company needs the capability to import its customers’ solid models, generate CNC code for lathes and mills directly from the models and quickly return the correct prototype or initial parts to customers at a competitive cost. To perform these functions, the company uses FeatureMill 2.5D, FeatureMill 3D and FeatureTurn from Delcam USA (Salt Lake City, Utah).

According to Eric Rosander, CNC programmer and machine operator at Innovative Precision, by using CNC milling, turning and grinding, the company can produce precision parts in virtually any shape, size or form to tight tolerances. The company uses various materials, including aluminum, mild steels, stainless steel, plastics and tool steels.

“Our shop focuses on accomplishing tight tolerance, intricate work with a quick turnaround,” Mr. Rosander says. “Typical tolerances range from 0.0003 inch to 0.0005 inch on the turning centers and 0.0005 inch to 0.002 inch on the machining centers and mills.” Operations include 3D surfacing, locating holes to other features, including ID and OD, as well as machining grooves, pockets, bores, bosses and threads.

FeatureCAM has been beneficial to Innovative Precision in several ways. The software has allowed the company to increase productivity, shorten programming time and customize programs as needed when dealing with high-precision work. If the company adds a tool that is not found in the software’s tool library, then the information for the new tool can be added to a tool crib specific to Innovative Precision.

Designed for ease of use, the Windows-based software includes wizards to walk users through several of the processes. According to Mr. Rosander, geometry tools enable him to create parts completely within the software because he can import customer files with no trouble.

“A lot of our customers come to us with solid models—IGES, Parasolid and SolidWorks files,” he continues. “FeatureCAM recognizes the features and helps to quickly move us through the programming for those parts, in turn saving us time. We can keep turnarounds to a minimum. So, we can produce custom parts cost-effectively.”

The software’s feature-based approach to CAM can also speed part generation. Other CAM systems are operations-based and require programming for each operation (one at a time) to create parts, the manufacturer says. Because manufacturing details are left to the machinist, users must specify the details for each tool and machining pass, which is a time-consuming process that may take days to complete. With FeatureCAM, users can employ automatically programmed operations to generate parts with features such as tapped holes, bosses, turned grooves and more. To modify any element of the part program, users need only change a few settings on a feature to create a whole new set of operations.

“We also like the fact that the new software helps us achieve significant increases in calculation speeds for 3D tool paths and improved surface finish,” Mr. Rosander adds.

The feature recognition model import capabilities are a big help to the company.

“The CAM software recognizes features and patterns in the solid model, such as holes and surfaces,” Mr. Rosander continues. “It can pull the geometry for you and write most of the program; and then you are done. For example, if I write a facing program, it might take about 15 minutes to write the program and ensure that all of the XYZ coordinates are correct. With the new package, the same type of work would take about 30 to 60 seconds to finish.”

One by-product of implementing the software has been identifying the optimum way to run parts, the company says. Like many shops, Innovative Precision works primarily with geometries. FeatureCAM selects the appropriate tool speeds, feeds and tool paths. Mr. Rosander relays an example of how it all ties together:

“I am working on an automotive part right now that the customer sent us as a solid model,” he explains. “This job entails work on all six sides, with holes that intersect with other holes and features. The software allows me to see that, to determine which feature to run first. The program makes it easier on me because I know that the numbers in the program for the part will match the solid model. I can view each hole and how it compares to the solid model. After that, all I have to do is put the part in and hit the ‘go’ button on the machining center.”

Mr. Rosander adds that personnel with no prior programming experience have been able to successfully program jobs within a week’s time.

In addition, Feature3D milling strategies can prolong tool life by keeping the load on the cutter as consistent as possible. The strategies can also help minimize sudden changes in the cutting direction that would put excessive load on the tool or require a slower feed rate. Strategies include arcing moves, a finishing combination, a spiral tool path and rest finishing.

With the rough and finish machining strategies, operators can use arcing moves when approaching and leaving the job. Similarly, arcs can link the various cutting moves. This is an alternative to the traditional approach of using right-angle moves that often require reduced cutting speeds and leave dwell marks.

Arcs can be inserted automatically into roughing tool paths as the tool approaches any steep face. Without the arc, there can be a sudden increase in the load on the tool as it engages the steep surface. To prevent damaging the tool, the feed rate must be reduced, thus increasing overall machining times. With the arcs added, the resultant smoother tool path can be run at higher speeds and with less tool wear, the manufacturer says.

With intricate parts that often come in the door as solid models and a complement of machine tools including lathes and mills, Innovative Precision relies on the FeatureCAM suite to quickly turn ideas into prototypes and prototypes into production.

Related Content

Five Safety Considerations for CNC Machinists

Safety in CNC environments is essential for users – and for productivity. Consider these 5 points to avoid injury, part failure and downtime.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreUnderstanding G27, G28, G29 and G30

Take a closer look at these reference position commands.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)