Getting High Part Yield, Rigid Part Clamping And Low Workholding Cost

JBJ Manufacturing mostly machines heavy parts of iron and steel used in drive trains and other systems for construction and agricultural equipment. The parts range from an inch square to parts longer than two feet. The company machines them in runs of just four or five parts up to 500 pieces. To be efficient and profitable with this kind of work, JBJ needed to take a creative approach with its workholding to be fast and flexible.

JBJ Manufacturing (Faribault, Minnesota) mostly machines heavy parts of iron and steel used in drive trains and other systems for construction and agricultural equipment. The parts range from an inch square to parts longer than two feet. The company machines them in runs of just four or five parts up to 500 pieces. To be efficient and profitable with this kind of work, JBJ needed to take a creative approach with its workholding to be fast and flexible.

"There are a lot of good multiple clamping systems on the market, but most of them are designed to hold parts made of softer materials such as die castings or small, rectangular parts that clamp rigidly and easily," says Bill Vos, one of the founding partners at JBJ Manufacturing. "Our work machining iron and steel requires aggressive milling cuts, so we looked for a part-holding system which was precise, quick to operate and had the extra rigidity we needed."

Mr. Vos and his partners (Jerry Vold, Jim Krueger and John Mickelson) set out to build a shop that was innovative and could respond to customers' needs. That meant running 24 hours a day, five days a week. They used dozens of standard vises on many of their machining centers, but they wanted something special. Early on, the four partners saw some limitations in standard, single station, screw type vises which were rugged enough but couldn't provide the size versatility needed for certain short run work that had to be produced and delivered quickly. Even multiple station vises weren't quite what JBJ Manufacturing wanted to rigidly clamp the iron and steel parts with the fast turn around that customers required.

Mr. Vos knew and used standard vises from Kurt Manufacturing Company (Minneapolis, Minnesota) throughout his manufacturing career and looked to Kurt for a solution. In talking to Kendeco Tool Crib (St. Cloud, Minnesota), a Kurt dealer who sold JBJ Manufacturing most of its vises and tooling, Mr. Vos became aware of the Kurt MoveLock, a two-piece vise that employs the AngLock concept for part clamping. The MoveLock's two components are the movable jaw and the base that covers the clamping mechanism.

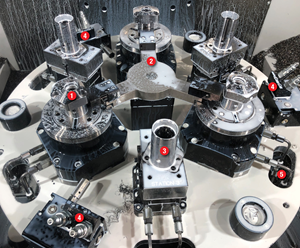

What turned Mr. Vos on to the MoveLock was its clamping rigidity, its potential to handle a very wide range of part sizes in multiples, and its ability to clamp up quickly just by tightening a single hex nut.

The Kurt MoveLock uses the AngLock concept for precision clamping. When the vise screw is tightened, the vise piston is driven forward locating on an internal segment. The lateral force clamps the part, while downward pressure is applied to the movable jaw. The downward pressure minimizes or prevents part lift. For every pound of clamping force on the part, there is a half-pound of force exerted down on the movable jaw. The MoveLock piston produces a repeatable 5/16-inch stroke at up to 4,000 pounds clamping pressure and affords quick and easy exchange of parts.

The Kurt MoveLock vise is made of 80,000 psi ductile iron to provide the strength and rigidity for tough, high horsepower machining cuts while it absorbs and damps any machine vibration that can occur.

Mr. Vos customized his MoveLock setup by designing mounting plates to fit the two Daewoo (Model DMV 400) pallet changer tables. Each plate (24 inches wide by 22 inches deep) was designed with 12 mounting slots machined into it allowing for infinite adjustment within the range of the machine table. Two of the MoveLocks are used on each vise table for holding two small parts or a single large part. Two parts of different sizes or different sides of similar parts can be held in place to maximize the three machining axes of the Daewoo machining center. The two-pallet setup allows for load-unload operations on one pallet while the machine is finishing the part(s) on the second pallet.

The part clamping setup is straightforward and manually operated so it has no pneumatic or other hookups to get in the way. It also has a low profile with no swivel handles to protrude or cause clearance problems when pallets rotate.

JBJ's setup can handle parts in the 500 to 1,000 pound class with the 180-degree rotating pallets indexing in 5 seconds. The machine is heavily ribbed, has Meehanite castings, integral box ways, oversized AC servos and powerful spindle motors. When equipped with the Kurt MoveLock workholding, JBJ gets the heavy cuts with tenths accuracy and mirror finishes when necessary.

Related Content

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreWhen To Use A Collet Chuck

Don't assume the standard chuck is the right workholding for every lathe application.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More