How Summer Heat is Affecting Your Parts

All machines have thermal shift. Follow these tips to keep your tolerances tight even as shop temperatures flucatuate in the warmer months.

Reader Question:

Our shop is taking in more tight-tolerance work, but we’re finding inconsistencies with our parts as it’s coming up on the warmer summer months. Can you offer some thoughts to help us maintain these tight tolerances even as our shop temperatures change?

Miller’s Answer:

Thermal issues are one of the hardest issues for any shop to face, and despite many advancements in CNC controllers and “thermal-friendly” design concepts, it’s still a constant in an industry as precise as ours.

One truth I’ve learned about this through the years is that all machines shift with temperature. I’ll repeat: all machines have thermal shift, no matter how expensive, what you were told by sales or what fancy marketing strategy was employed. The difference, however, is to what severity do they shift, and what is the nature of that expansion.

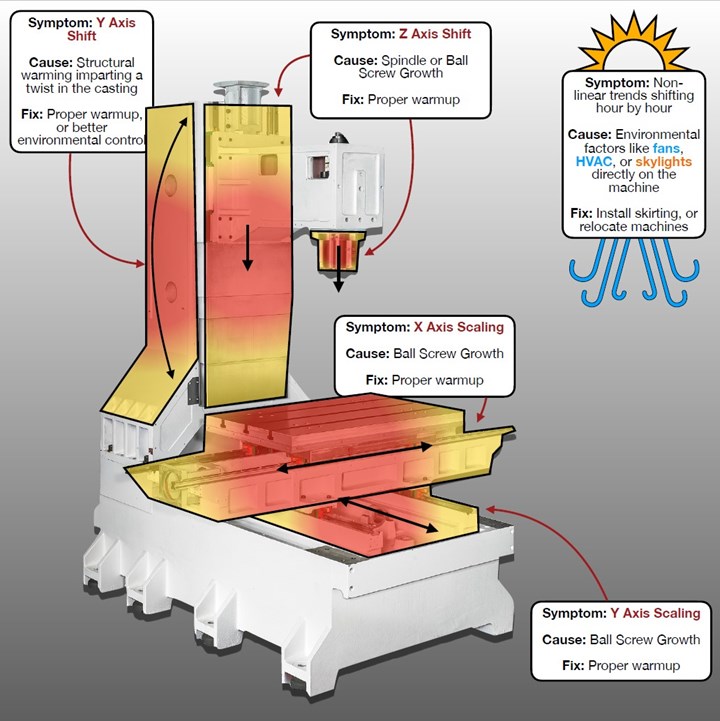

Most shops are familiar with spindle elongation and it’s the simplest to understand. The spindle — being the most energetic part of the machine — warms up over time, and due to the nature of the metals used to construct it, that structure grows along the Z-axis. As a result, tools cut deeper than they would have previously. This can also apply to the axes. As the ball screw warms through movement, it elongates. Lastly, as all this heat eventually saturates through the structure of the machine, we may see the structure warp and twist. All this is generally happening in the scale of 0.100 mm (0.004") or less. Enough to make previously good parts into scrap.

There is an important distinction to be made as all these components warm up. Some exhibit signs of scaling, while others may just be a shift. Scaling implies we cut things larger than we did with a cold machine. Shift means locations of part features may be in a different position than they were previously. Scaling occurs from spindle and axes warming, while shift typically occurs from the structure warming. Studying these differences and collecting more frequent part data will direct you to what is happening, and perhaps how to make the right offset moves to mitigate its impact.

After you understand how the machine is behaving, identifying the source is also important. There are two primary sources of heat for a machine: the environment and the machine itself. Machines can be impacted by many environmental factors, including the sun through a skylight, drafts from open bay doors or nearby equipment like compressors and parts washers. If you already have a well-maintained shop temperature and fair surrounding conditions, then the machines thermal shift is probably self-induced.

If you find the environment is to blame, then relocation of the machine or the sources may be the answer. If the machine expansion is determined to be self-induced, then next we need to implement proper machine warmup protocols.

With regard to the machine’s self-warming, the best way to reduce its impact to part quality is with a proper machine warmup. Most machines will have a bare-minimum spindle warmup time, for example less than 1,000 rpm for five minutes. However, this is much more a lubrication exercise than a temperature one. If you want to cut your most accurate parts, a warmup routine is a must. This routine should move all the axes at a reasonable feedrate common to your parts, with the spindle turning at an rpm, again, common to your parts for 30 minutes to an hour. I’ve found this timeframe is where most machines will reach their saturation. This means all the heat created by the machine is matched by the machine’s cooling accessories and the environment it is in, and the opportunity for further thermal expansion or shift is at the reasonable limit. It’s also a good strategy to do this warm up before your first article parts. In this way, your offset adjustments reflect a machine ran in its most median state.

Do not try to shortcut this warmup. Running the machine at full rapid across the full strokes for five furious minutes at full rpm will not shorten this process. This will more likely overshoot the heat that the machine would make in a normal cycle, and you’ll see thermal shift from the machine cooling down to its normal operating temperature.

When it comes to the machine itself, most commodity machines will not have very much in the ways of mechanical cooling, meaning chillers, or oil recirculation that you see on higher end machines. All machines these days will have some type of “digital cooling” or a thermal algorithm running in the background. This algorithm is meant to add or subtract the right amount from the programmed values to compensate for the heat induced. In my experience, some of them work great, and some do more harm than good through over adjustments or inconsistent adjustments because it was trained in conditions that are different than what you are running. If it’s possible, try turning it off or reducing it to quiet the noise you may be seeing in your data.

With regards to the parts themselves, the material they are made from can behave differently. Generally, iron and steel parts will track with the machine because it is made of the same materials. A well-saturated machine in a stable temperature environment can be adjusted 1:1 based on the inspection report. Aluminum or plastics will not behave the same, so it’s important to check the parts themselves in a stable environment with gauges that are also saturated in that environment before making any critical adjustments.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)