How to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

When determining the dimensional length of a part, there are probably hundreds of tools available, starting with a simple vernier caliper up to a high-end coordinate measuring machine (CMM). These tools — and everything in between — can produce a result but it may not be the best result in terms of ease of use, cost and practicality for the dimension being checked.

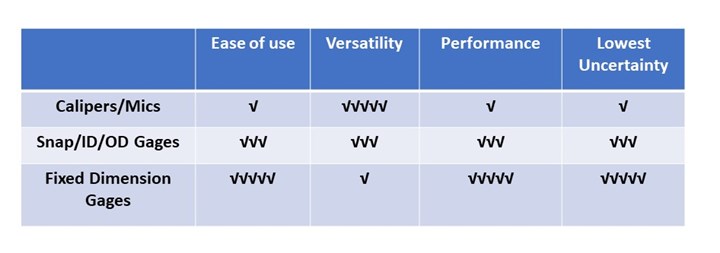

Much depends on the accessibility and tolerance of the dimension, how many parts need to be checked and by whom. Oftentimes, in the real world — where the part is being produced — a good, better or best guide can be helpful. There is never a logical decision tree for making these choices, but by understanding some principles and asking the right questions, good results can be obtained faster.

When versatility is required and tolerances are not too tight, one can achieve good results by measuring a part with hand tools such as calipers and micrometers. These hand tools are referred to as measuring instruments because they have the standard or reference scale integral to the instrument. With a mechanical micrometer, the standard is the screw thread in the thimble, while with digital micrometers or calipers, it is the electronic scale or encoder within the tool.

With these tools, the part is measured against the internal standard. These measuring instruments offer a lot of versatility since they have a very long measuring range, but on the other hand, they will be slower to use and require more operator skill to obtain the best result. For basic measuring tasks, nothing beats the versatility of a caliper or micrometer. But once we start to get into a higher production environment with tighter tolerances, there is a better way.

An adjustable gaging instrument is the first step towards getting better results that are faster, easier to use and more precise. Instead of being universal with an internal scale, this gage class is more dedicated to the task. Snap gages of outer diameters (ODs) or bench inner diameters (ID)/OD gages fall into this group. They are dedicated to the specific task and use an external standard from which the part is compared. Thus, they are often referred to as comparative gages. These typically have a large adjustable range but a very short comparative range, and tend to have much higher resolution for the result.

With these gages, the instrument is adjusted and set to size using a master ring or disc. The gage is then locked into place for the dimension and sample parts are compared — smaller or larger — to the master setting. Since this dedicated gage is now set for one dimension, it becomes very fast and easy to use for the operator. The part can go into the gage only one way; often, the part can be placed in the gage and released by the user, producing a result free of any operator error. And depending on the readout device and construction of the comparative gage, high-precision results are obtained.

However, for the best results in a production environment, a comparative gage with the benefits above is made, but dedicated to the specific size being checked. This gage class would include air gaging for IDs or ODs or a fixed-size, mechanical-plug gage. Because these gages are dedicated to the specific dimensional check, they are by far the fastest and easiest to use. Since they are still comparative gages, an external master of the nominal size is required to set the reference the parts are compared to.

The part can be measured only one way, it goes onto the gage quickly, and there is absolutely no operator influence. Therefore, the comparative gaging results tend to be the best in terms of repeatability, precision and overall certainty of measurement because they eliminate most of the user-influenced and gage-design errors.

There are many factors to consider when choosing the correct measuring or gaging solution that best meet the application; however, once these factors are known, along with the performance characteristics of the gaging options, the best choice for the task can be made.

Related Content

How to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreBuilding an Automation Solution From the Ground Up

IMTS 2022 provides visitors the opportunity to meet with product experts to design automation solutions from scratch.

Read MoreDetermining Out-of-Roundness at the Point of Manufacture

George Schuetz, Mahr Inc.’s Director of Precision Gages, offers these techniques for measuring roundness on the shop floor.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)