Inner-Diameter Part Clamping Offers Lathes Complete Outer-Diameter Access

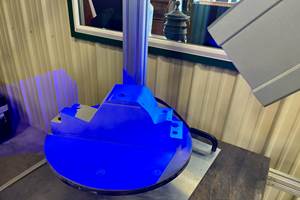

Royal Products' CNC expanding mandrels provide access to the entire outer diameter of the workpiece.

Gripping a workpiece by its inner diameter (ID) rather than its outer diameter (OD) is a workholding option that many job shops fail to consider when turning or grinding parts. However, this technique offers a number of advantages, especially in the machining of workpieces with complex surfaces. Royal Products (Hauppauge, New York) produces a series of CNC expanding mandrels designed for a range of spindle types that it says offers more flexibility in workholding than people might think.

According to Tom Sheridan, Royal’s vice president of marketing, expanding mandrels can be used to grip any workpiece that has a suitable inner bore diameter and which lends itself to being completely machined on the outside. The suitability of a workpiece’s inner bore is application-specific; Mr. Sheridan generally advises that there be, at most, a 3:1 length-to-diameter ratio of the inner bore. However, it is possible to accommodate higher ratios depending on a variety of factors, such as the type of material being machined or the aggressiveness of the cut. Expanding mandrels are especially useful when a workpiece requires secondary machining operations because these devices enable external diameters to be turned in a single operation, increasing concentricity between the two operations. They also prevent damage to previously machined surfaces, which is why expanding mandrels are often used on lathe subspindles. The access they provide to a workpiece’s entire outer surface also makes them well-suited for use on lathes with live tooling.

Another possible application is when a part has a lot of external features or there are changes in its diameter. In this case, the available gripping length on the OD may be limited. However, if the workpiece has a suitable inner bore, an expanding mandrel can be used to grip the workpiece along a significant length on the ID, therefore increasing engagement with the mandrel and rigidity of the hold. This is especially applicable in industries such as gear-making, Mr. Sheridan says.

Royal’s expanding mandrel systems are made of three major components. The first is the body, which acts as the interface to the machine tool and contains a threaded piece called the drawtube connector. This connector is custom-machined for each individual machine’s drawtube. According to Mr. Sheridan, this helps to simplify installation of the mandrel system onto the machine. The second major component contains three individual parts: an adapter that connects an expanding pin to the drawtube connector, the expanding pin and the mandrel itself. The mandrel contains a male taper that corresponds to a female taper on the third main component of the system, which is the expanding sleeve. The system works by sliding the expanding sleeve over the mandrel, locking it into place with a pin and drawing the mandrel back axially using the machine’s drawtube. This motion pulls the expanding sleeve further back onto the mandrel, causing the two tapers to interfere and the mandrel to expand.

Mr. Sheridan says one key feature of Royal’s line of CNC expanding mandrels is that the segments of the sleeve are able to expand parallely, maintaining contact with the workpiece over their whole length in order to eliminate the risk of distortion, particularly with thin-walled parts. This parallel grip also increases accuracy, grip force and torque transmission.

However, it is the combination of features that makes Royal’s expanding mandrels stand out, Mr. Sheridan says. The line is standardized on the most common gripping ranges and spindle types, and the company maintains a database of machine tool spindles and drawtubes to enable customization of drawtube connectors. Additionally, Royal offers a number of specialized systems to fit each company’s individual needs. Royal can supply systems with multiple expanding sleeves or mandrels that can support workpieces with IDs as large as 25 inches. Although typically used in turning or grinding applications, Royal’s expanding mandrels can be adapted for use on milling machines with special fixtures, as well.

The standard line of expanding mandrels consists of five possible mandrel models with four different body assemblies. The mandrel models are determined based on the ID of the workpiece and its corresponding gripping range, while the body assemblies are based on the four most common spindle types: A2-5, A2-6, 140 mm and A2-8. Model A features a gripping range of 0.479 to 0.640 inch, model B ranges from 0.620 to 0.901 inch, model C ranges from 0.870 to 1.151 inches, model D ranges from 1.120 to 1.651 inches, and model E ranges from 1.620 to 2.526 inches. Expanding sleeves are sold separately in a variety of gripping ranges. Optional part locators are available if required.

Related Content

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreSimple Workholding for Robotic Automation

Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)